Road pipe trench quick backfill material produced with building wastes and construction technology thereof

A technology for construction waste and pipe trenches, which is applied in the field of low-strength concrete, and can solve problems such as unfavorable manual excavation and difficult backfilling materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

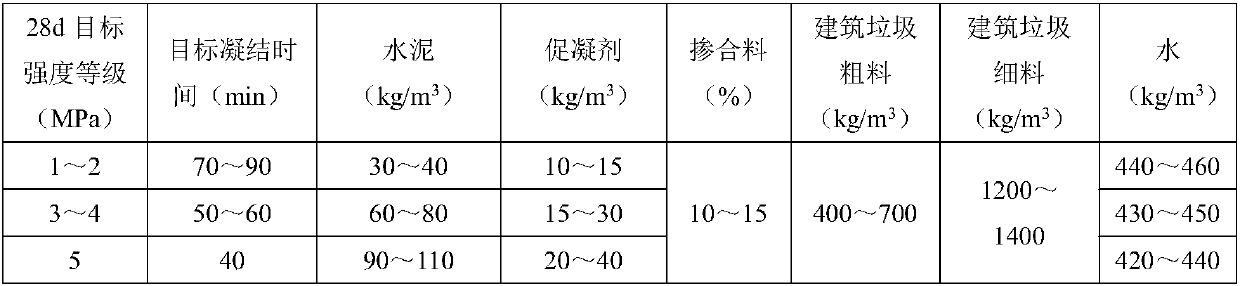

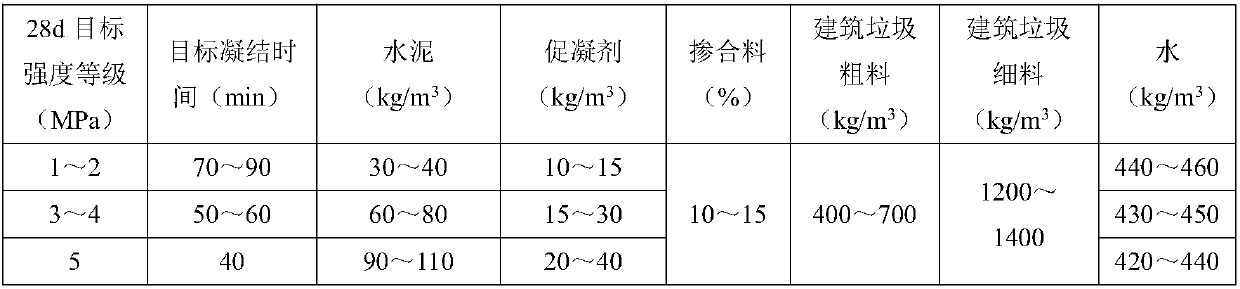

Method used

Image

Examples

specific Embodiment approach

[0087] Due to pipeline protection and narrow building boundaries, large-scale compaction machines cannot be used for backfilling construction of road trenches in a certain city. At the same time, due to traffic conditions, traffic needs to be opened as soon as possible. Adopt the quick backfill material of urban road trench that utilizes construction waste production factory to mix type provided by the present invention as backfill material, and specific implementation is as follows:

[0088] Construction materials: The cement used is ordinary Portland cement with a strength grade of 42.5R; the recycled construction waste aggregate is produced by a recycling plant, and the moisture content of the recycled coarse material is 3%, and the moisture content of the recycled fine material is 3%, which meets the above recycling requirements. Aggregate technical requirements; fly ash is Class F Class I, with a moisture content of 2%, and its quality complies with national technical stan...

Embodiment 2

[0098] There is a road surface collapse in a certain urban road, which needs to be backfilled. The urban road pipe ditch fast backfill material provided by the invention is used as the backfill material, and the specific implementation method is as follows:

[0099] Construction materials: The cement used is ordinary Portland cement with a strength grade of 42.5R; the recycled construction waste aggregate is produced by a recycling plant, and the moisture content of the recycled coarse material is 4%, and the moisture content of the recycled fine material is 4%. Aggregate technical requirements; fly ash is class F class Ⅲ, moisture content is 5%, and its quality is in line with national technical standards; water is potable tap water.

[0100] construction process:

[0101] 1. Clean up the foundation pit: remove the dross, floating soil and other sundries in the foundation pit, and tamp and level it, and the edge parts are cut neatly.

[0102] 2. Construction machinery: 2 man...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com