Rust-proof corrosion-resistant non-shrinkage concrete for blast furnace and preparation method thereof

A non-shrinkage, concrete technology, applied in the field of building materials, can solve the problems of high cost and increased risk of use, and achieve the effects of improved corrosion resistance, easy control of construction time, and good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Preparation of concrete

[0044] Relying on the general contracting project of No. 1 and No. 2 blast furnace projects of Vietnam Formosa Ha Tinh Iron and Steel Industrial Co., Ltd. By selecting raw materials such as Vietnam's local concrete cement, sand, stone, and admixtures, the concrete mix ratio is designed, mainly by adding a certain amount of rust inhibitor, furnace stone powder and expansion agent to the concrete mix ratio. Because the project is located in Ha Tinh, Vietnam In the coastal area of Qiying County, the geological survey report shows that the groundwater in the blast furnace area contains a large amount of chloride ions and sulfate ions. The high corrosion resistance requirements of buildings in coastal areas can be met by adding rust inhibitors, and the design strength level is C45.

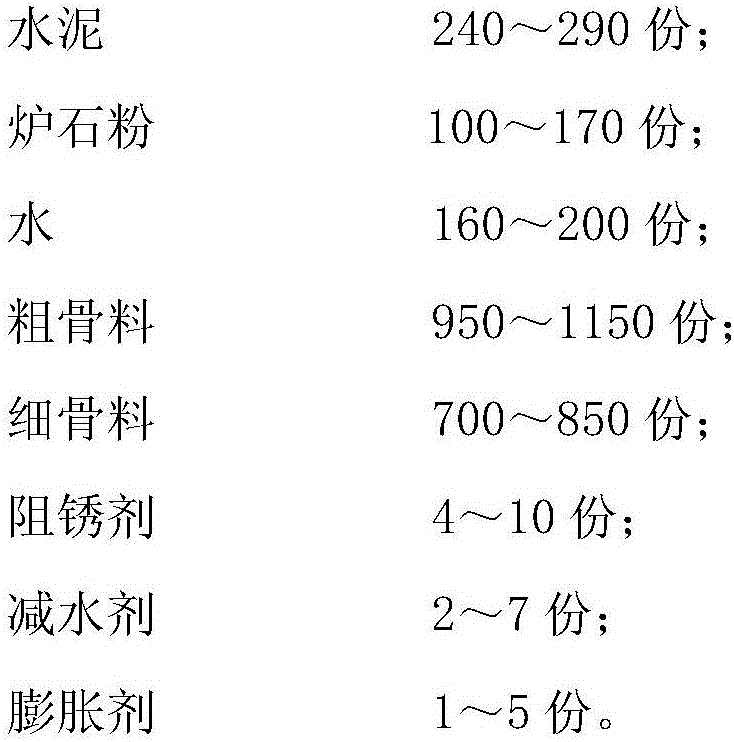

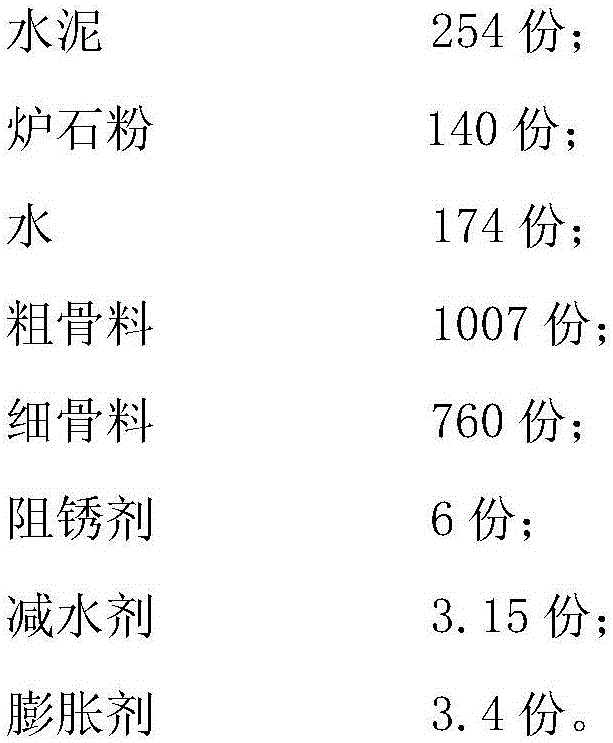

[0045] Table 1 Components and their weight ratios

[0046]

[0047] The raw material cement in the embodiment adopts PCB40 cement (equivalent to domestic commo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com