Alkali-activated cementing material capable of controlling setting time as well as control method and application thereof

A technology for setting time, cementitious materials, with applications in climate sustainability, sustainable waste treatment, cement production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

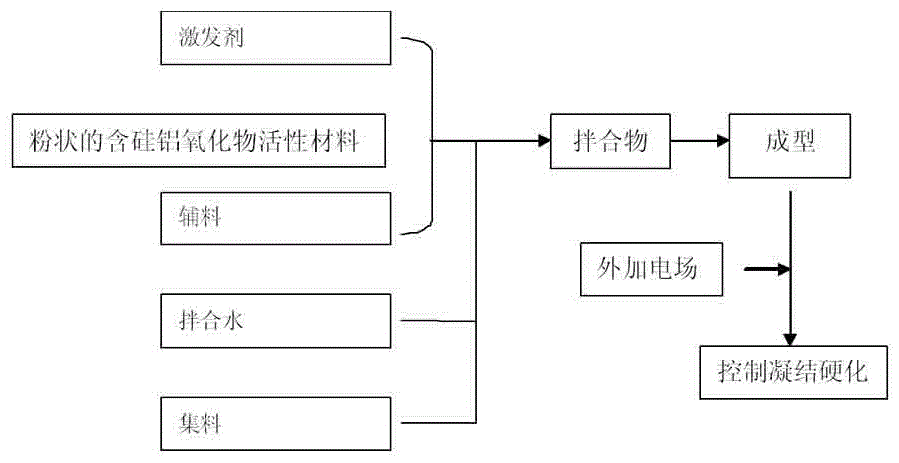

Method used

Image

Examples

Embodiment 1-6

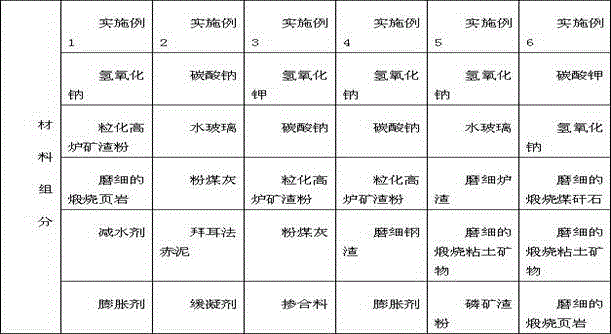

[0033] Embodiments 1-6, an alkali-activated gelling material that can control the setting time, the specific components of each embodiment are shown in the following table:

[0034]

Embodiment 7

[0036] A kind of alkali-activated gelling material that can control the setting time, the mass composition range of the gelling material is: 60 parts of powdery silicon-containing aluminum oxide active materials, with Na 2 O+0.658K 2 3 parts of activator calculated by O, 2 parts of water reducer and 3 parts of retarder.

Embodiment 8

[0038] A kind of alkali-activated gelling material that can control the coagulation time. The mass composition range of the gelling material is: 80 parts of powdery silicon-containing aluminum oxide active materials, with Na 2 O+0.658K 2 O calculated activator 5 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com