Preparation method of low-alkali polymer high-efficient liquid setting-accelerator for sprayed concrete

A technology of liquid quick-setting agent and sprayed concrete, which is applied in the field of building materials, can solve the problems of large amount of slurry falling and rebound, physical hazards of construction workers, and single performance, so as to reduce the amount of rebound and dust, and improve all aspects performance, no irritating odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

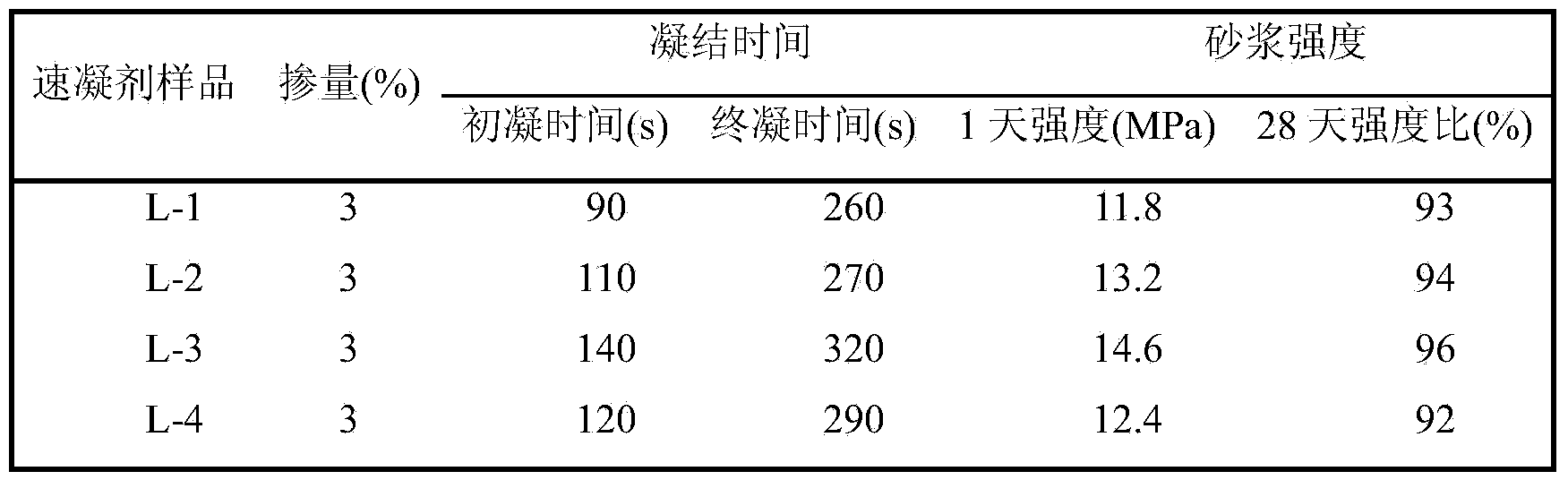

Examples

Embodiment 1

[0029] The preparation method of low-alkali polymer high-efficiency liquid accelerator for shotcrete is realized through the following steps: 1) Preparation of aluminate mother liquor

[0030] Add 35% potassium hydroxide and 45% aluminum hydroxide to 20% water by mass, and stir with an electric stirring bar for 3 hours at a temperature of 120°C to prepare an aluminate mother liquor;

[0031] 2) Preparation of modifier

[0032] Dissolve 20% sodium carbonate in water, heat to 70°C, then add 40% sodium silicate, react for 0.5h, and form a transparent solution, which is the modifier;

[0033] 3) Preparation of low-alkali polymer high-efficiency liquid accelerator

[0034] Add the aluminate mother liquor obtained in step 1) into a three-necked flask, perform high-speed shear stirring at 500rpm / min, and simultaneously add the modifier prepared in step 2) to obtain a mixed solution. The modifier and aluminate The mass ratio of the mother liquor is 1:2, and the temperature is 60°C. ...

Embodiment 2

[0035] The preparation method of the low-alkali polymer high-efficiency liquid quick-setting agent for shotcrete is realized through the following steps:

[0036] 1) Preparation of aluminate mother liquor

[0037] Add 35% potassium hydroxide and 45% aluminum hydroxide to 20% water by mass, and stir with an electric stirring bar for 3 hours at a temperature of 120°C to prepare an aluminate mother liquor;

[0038] 2) Preparation of modifier

[0039] Dissolve 16% sodium carbonate in water, heat to 70°C, then add 30% sodium silicate, react for 0.5h, and form a transparent solution, which is the modifier;

[0040] 3) Preparation of low-alkali polymer high-efficiency liquid accelerator

[0041] Add the aluminate mother liquor obtained in step 1) into a three-necked flask, perform high-speed shear stirring at 500rpm / min, and simultaneously add the modifier prepared in step 2) to obtain a mixed solution. The modifier and aluminate The mass ratio of the mother liquor is 1:1, and the...

Embodiment 3

[0043] The preparation method of the low-alkali polymer high-efficiency liquid quick-setting agent for shotcrete is realized through the following steps:

[0044] 1) Preparation of aluminate mother liquor

[0045] Add 30% sodium hydroxide and 45% aluminum hydroxide by mass to 25% water, and stir with an electric stirring bar for 3 hours at a temperature of 120°C to prepare an aluminate mother liquor;

[0046] 2) Preparation of modifier

[0047] Dissolve 16% sodium carbonate in water, heat to 70°C, then add 30% sodium silicate, react for 0.5h, and form a transparent solution, which is the modifier;

[0048] 3) Preparation of low-alkali polymer high-efficiency liquid accelerator

[0049] Add the aluminate mother liquor obtained in step 1) into a three-necked flask, perform high-speed shear stirring at 500rpm / min, and simultaneously add the modifier prepared in step 2) to obtain a mixed solution. The modifier and aluminate The mass ratio of the mother liquor is 1:1, and the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com