Super-early-strength type ultra-high performance concrete and preparation method thereof

An ultra-high-performance, ultra-early-strength technology, applied in the field of building materials, can solve problems such as inability to repair quickly, and achieve the effect of improving compactness, long working time and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

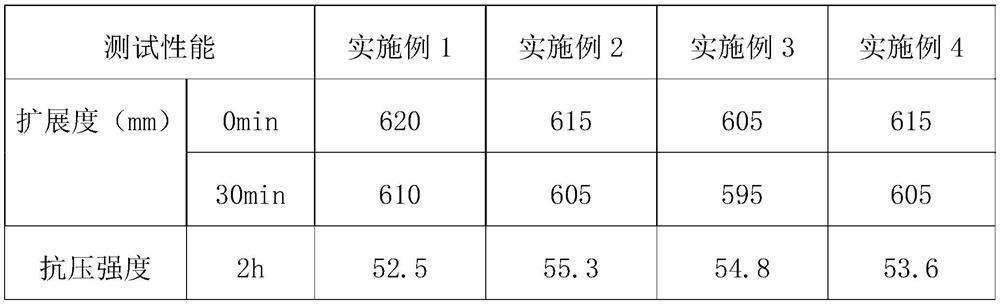

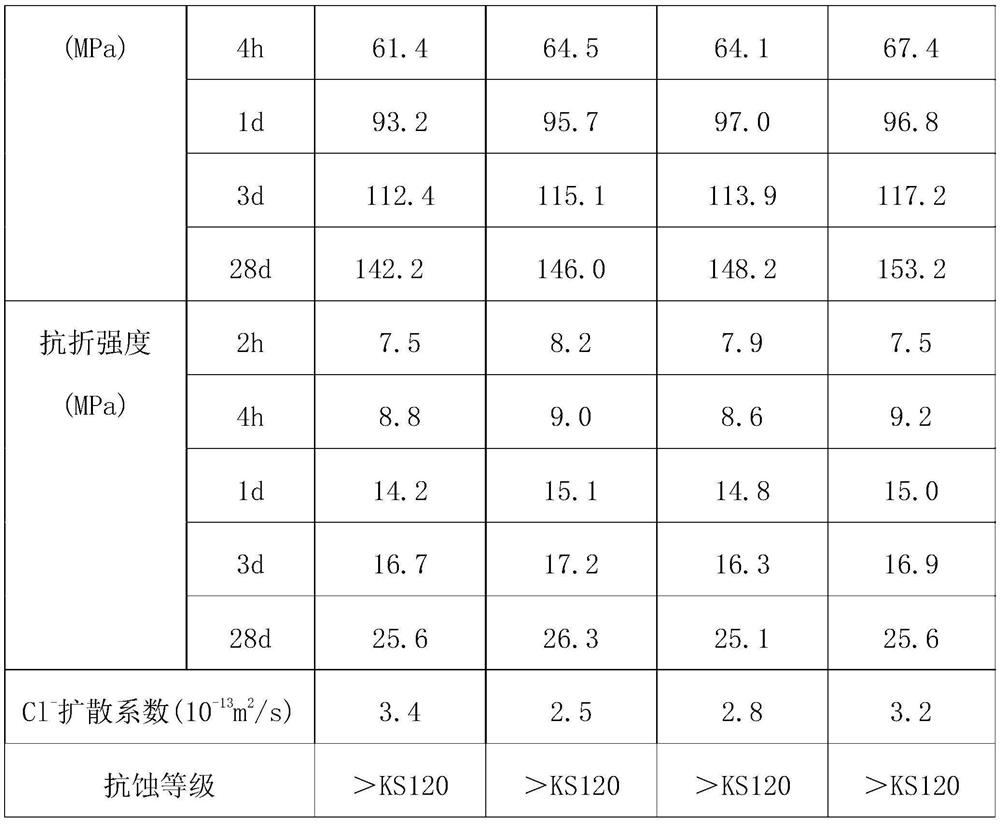

Examples

preparation example Construction

[0040] The preparation method of the above-mentioned ultra-early-strength ultra-high performance concrete comprises the following steps:

[0041] Pre-mix the cement, silica fume, fly ash, aggregate, retarder and slaked lime in the formulated amount for 1-10 minutes, add the formulated amount of water and water reducing agent, stir for 5-15 minutes until the slurry is produced, and finally add the formulated amount A small amount of steel fiber and coagulant, stirred for 1-10 minutes, moved into the mold, cured and demoulded, to obtain ultra-early-strength ultra-high performance concrete.

Embodiment 1

[0043] A super-early-strength ultra-high-performance concrete, comprising the following components in parts by weight:

[0044] 50 parts of cement, 10 parts of silica fume, 5 parts of fly ash, 80 parts of aggregate, 2 parts of slaked lime, 25 parts of steel fiber, 5 parts of water reducing agent, 0.5 part of retarder, 0.2 part of coagulation accelerator, 30 parts of water .

[0045] Among them, the cement is R·SAC42.5 type rapid hardening sulfoaluminate cement, and the specific surface area of the cement is 360m 2 / kg.

[0046] The specific surface area of silica fume is 15000m 2 / kg, the activity index of silica fume is 106%, SiO in silica fume 2 The mass content is 95%.

[0047] The specific surface area of fly ash is 550m 2 / kg, the loss on ignition of fly ash is 3.6%, and the water demand ratio of fly ash is 94%.

[0048] The aggregate is quartz sand, the fineness modulus of the aggregate is 1.9, and the crushing value of the aggregate is 6%.

[0049] Slaked l...

Embodiment 2

[0056] A super-early-strength ultra-high-performance concrete, comprising the following components in parts by weight:

[0057] 100 parts of cement, 30 parts of silica fume, 20 parts of fly ash, 150 parts of aggregate, 0.1 part of slaked lime, 5 parts of steel fiber, 1 part of water reducing agent, 0.05 part of setting retarder, 0.01 part of setting accelerator, 10 parts of water .

[0058] Among them, the cement is R·SAC52.5 type rapid hardening sulfoaluminate cement, and the specific surface area of the cement is 370m 2 / kg.

[0059] The specific surface area of silica fume is 16000m 2 / kg, the activity index of silica fume is 105%, SiO in silica fume 2 The mass content is 93%.

[0060] The specific surface area of fly ash is 580m 2 / kg, the loss on ignition of fly ash is 3%, and the water demand ratio of fly ash is 95%.

[0061] The aggregate is machine-made sand, the fineness modulus of the aggregate is 2.7, and the crushing value of the aggregate is 10%.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com