Method for controlling setting and hardening processes of magnesium phosphate cement

A magnesium phosphate cement and magnesium phosphate technology, applied in the field of magnesium phosphate cement, can solve the problems that the initial setting time of the magnesium phosphate cement slurry is less than 5 minutes, cannot meet the strength requirements of the repair project, and the early strength of the magnesium phosphate cement system decreases. Achieve the effect of quick repair of early strength and fast hardening in the operable time of construction, solve the insufficient construction preparation time, and solve the effect of excessively fast setting and hardening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

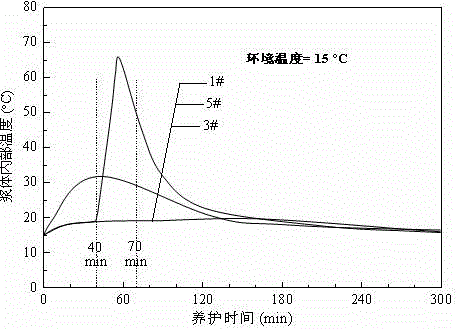

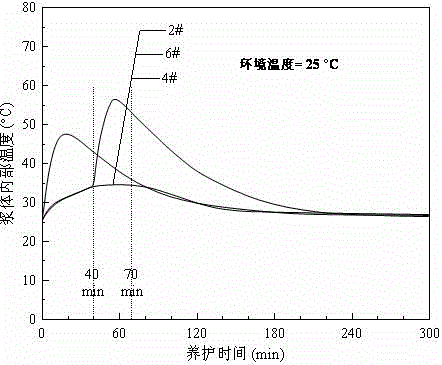

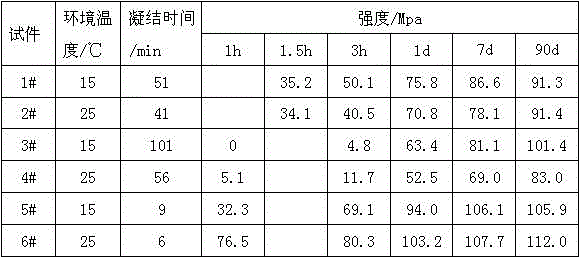

[0035] In order to verify the experimental effect of the present invention, the applicant has carried out specific examples to verify the beneficial effect of the present invention. During verification, 6 test pieces were prepared by using the method of the present invention and the reference method.

[0036]For 1# and 2# test pieces, adopt the method of the present invention to prepare, namely after pouring the cement slurry, first place it at room temperature for curing for 40 minutes, then move it to 50°C for curing for 30 minutes, remove the formwork after final setting, and then Place it under normal temperature for curing, and test the compressive strength of the specimens for 1.5 hours, 3 hours, 1 day, 7 days and 90 days; for 3# and 4# specimens, the dosage of borax retarder is respectively 10% and 15% of the mass of magnesium are prepared by the benchmark method, that is, after the cement slurry is poured, it is cured at room temperature, and the compressive strength o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com