Hydrophobic composite biological activity coating on surface of pure-magnesium or magnesium alloy and preparation method of hydrophobic composite biological activity coating

A bioactive, magnesium alloy technology, applied in the field of pure magnesium or magnesium alloy surface hydrophobic composite bioactive coating and its preparation, can solve the problems of unfavorable protection, micro-arc oxidation coating cracks, poor induction ability of calcium and phosphorus salts, etc. Achieve high density, improve corrosion resistance, and improve osteoinductive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a hydrophobic composite bioactive coating on the surface of pure magnesium or magnesium alloy, the specific steps are:

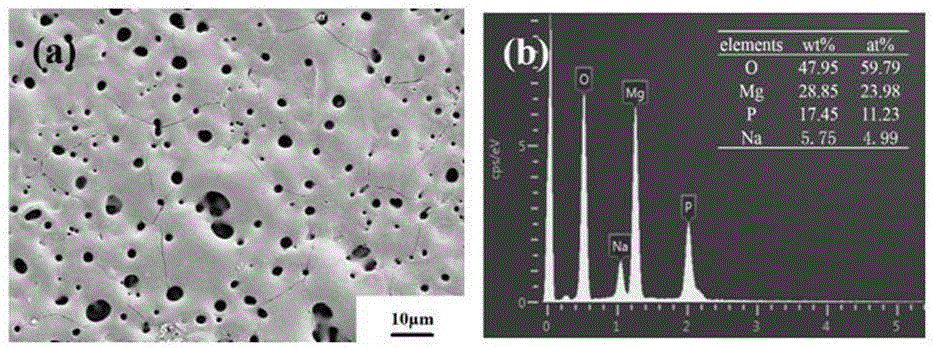

[0032] 1) Preparation of micro-arc oxidation coating on the surface of magnesium alloy:

[0033] Taking the treated magnesium alloy as the anode and the stainless steel plate as the cathode; placing the anode and the cathode in the electrolyte, and performing micro-arc oxidation for 10 minutes; wherein the electrolyte is sodium phosphate with a concentration of 50g / L and 5g / L Aqueous solution of L sodium hydroxide;

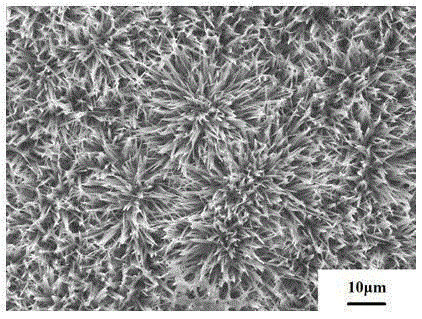

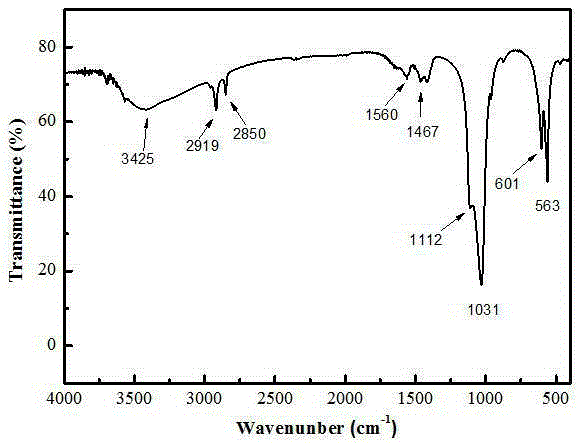

[0034] 2) Preparation of hydroxyapatite coating:

[0035] Prepare the electrolytic solution for electrodepositing hydroxyapatite, the composition of each solute is: ammonium dihydrogen phosphate of 0.042mol / L, calcium nitrate of 0.025mol / L and hydrogen peroxide of 10ml / L; The arc oxidation coating is used as the cathode, and the graphite rod is used as the anode, which is inserted into the electrolyte for electrod...

Embodiment 2

[0039] A method for preparing a hydrophobic composite bioactive coating on the surface of pure magnesium or magnesium alloy, the specific steps are:

[0040] 1) Preparation of micro-arc oxidation coating on the surface of magnesium alloy:

[0041] Taking the treated magnesium alloy as the anode and the stainless steel plate as the cathode; placing the anode and the cathode in the electrolyte, and performing micro-arc oxidation for 10 minutes; wherein the electrolyte is sodium phosphate with a concentration of 50g / L and 5g / L Aqueous solution of L sodium hydroxide;

[0042] 2) Preparation of hydroxyapatite coating:

[0043]Prepare the electrolytic solution for electrodepositing hydroxyapatite, the composition of each solute is: ammonium dihydrogen phosphate of 0.042mol / L, calcium nitrate of 0.025mol / L and hydrogen peroxide of 10ml / L; The arc oxidation coating is used as the cathode, and the graphite rod is used as the anode, which is inserted into the electrolyte for electrode...

Embodiment 3

[0047] A method for preparing a hydrophobic composite bioactive coating on the surface of pure magnesium or magnesium alloy, the specific steps are:

[0048] 1) Preparation of micro-arc oxidation coating on the surface of magnesium alloy:

[0049] Taking the treated magnesium alloy as the anode and the stainless steel plate as the cathode; placing the anode and the cathode in the electrolyte, and performing micro-arc oxidation for 10 minutes; wherein the electrolyte is sodium phosphate with a concentration of 50g / L and 5g / L Aqueous solution of L sodium hydroxide;

[0050] 2) Preparation of hydroxyapatite coating:

[0051] Prepare the electrolytic solution for electrodepositing hydroxyapatite, the composition of each solute is: ammonium dihydrogen phosphate of 0.042mol / L, calcium nitrate of 0.025mol / L, hydrogen peroxide of 10ml / L; The arc oxidation coating is used as the cathode, and the graphite rod is used as the anode, which is inserted into the electrolyte for electrodepo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com