Alpha high-strength gypsum based self-leveling material prepared by adopting phosphogypsum and production process thereof

A production process, high-strength gypsum technology, applied in the field of building materials, to achieve the effect of increasing strength, improving physical properties, and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

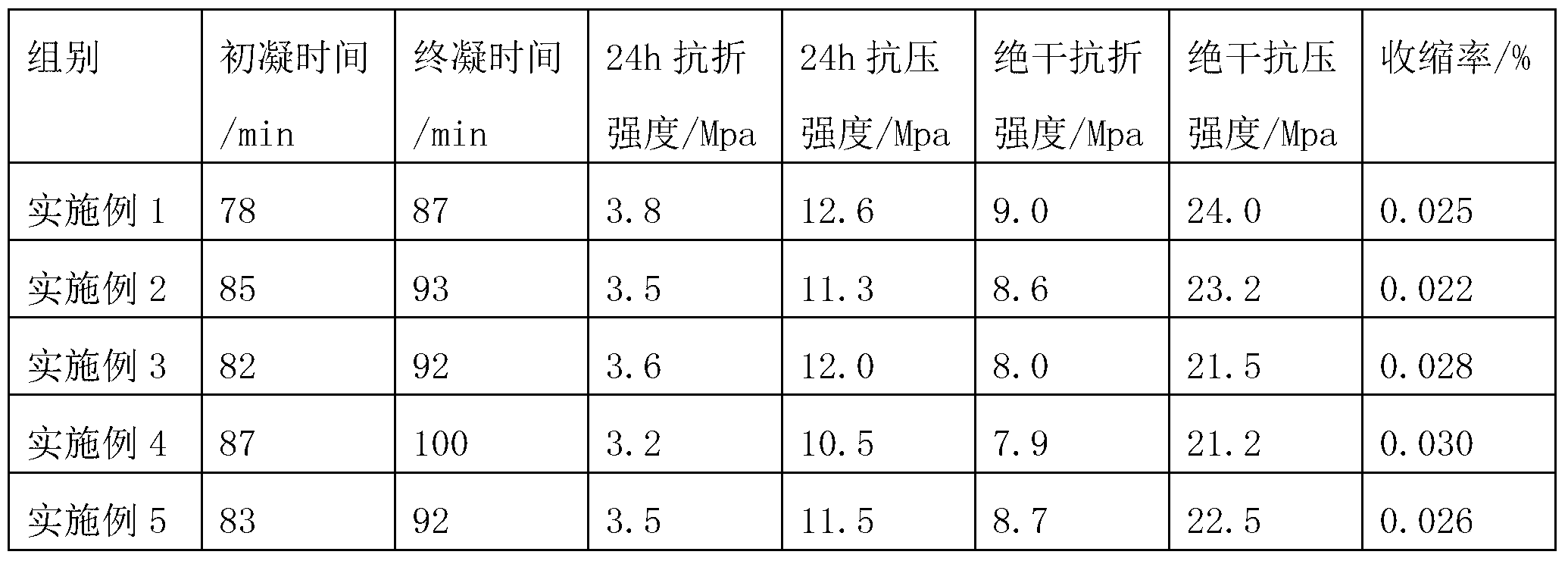

Examples

Embodiment 1

[0018] The production process of using phosphogypsum to prepare α-high-strength gypsum-based self-leveling materials, the proportion of each component is as follows:

[0019] 1) Prepare α high-strength gypsum powder from phosphogypsum:

[0020] Modified phosphogypsum: 60%; water: 29.6%; calcium chloride: 10%; tartaric acid: 0.4%;

[0021] Put the raw materials into the reaction kettle according to the above ratio, stir and mix to make a slurry, heat up to 95°C, then keep it warm for 5 hours, and carry out hydrothermal reaction under normal pressure, so that the dihydrate gypsum is dehydrated and transformed into α high-strength gypsum; ℃ hot water washing, solid-liquid separation, to obtain α high-strength gypsum slurry, and quickly dry at 100 ℃ to obtain α high-strength gypsum powder;

[0022] 2) Use α high-strength gypsum powder to prepare gypsum-based self-leveling materials:

[0023] α high-strength gypsum powder: 60%; fine river sand: 30.45%; sulfoaluminate cement: 3%; ...

Embodiment 2

[0026] The production process of using phosphogypsum to prepare α-high-strength gypsum-based self-leveling materials, the proportion of each component is as follows:

[0027] 1) α high-strength gypsum powder made from phosphogypsum: (Adjust the following marked data at the upper and lower limits, marked in blue)

[0028] Modified phosphogypsum: 50%; water: 39.5%; calcium chloride: 10%; tartaric acid: 0.5%;

[0029] Put the raw materials into the reaction kettle according to the above ratio, stir and mix to make a slurry, heat up to 98°C, then keep it warm for 4 hours, and carry out hydrothermal reaction under normal pressure to dehydrate the dihydrate gypsum into α high-strength gypsum; After washing with hot water at ℃ and separating the solid and liquid, the α-high-strength gypsum slurry is obtained, and quickly dried at 95°C to obtain the α-high-strength gypsum powder;

[0030] 2) Use α high-strength gypsum powder to prepare gypsum-based self-leveling materials:

[0031]α...

Embodiment 3

[0034] The production process of using phosphogypsum to prepare α-high-strength gypsum-based self-leveling materials, the proportion of each component is as follows:

[0035] 1) Prepare α high-strength gypsum powder from phosphogypsum:

[0036] Modified phosphogypsum: 40%; water: 44.8%; calcium chloride: 15%; tartaric acid: 0.2%;

[0037] Put the raw materials into the reaction kettle according to the above ratio, stir and mix to make a slurry, heat up to 92°C, then keep it warm for 6 hours, and carry out hydrothermal reaction under normal pressure to dehydrate the dihydrate gypsum into α high-strength gypsum; ℃ hot water washing, solid-liquid separation, to obtain α-high-strength gypsum slurry, and quickly dry at 92°C to obtain α-high-strength gypsum powder;

[0038] 2) Use α high-strength gypsum powder to prepare gypsum-based self-leveling materials:

[0039] α high-strength gypsum powder: 50%; fine river sand: 38.95%; sulphoaluminate cement: 4%; fly ash: 4%; redispersible...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com