Self-healing backwater surface waterproof material capable of stopping open water, preparation method and application thereof

A waterproof material, backwater technology, used in building insulation materials, water conservancy projects, climate sustainability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

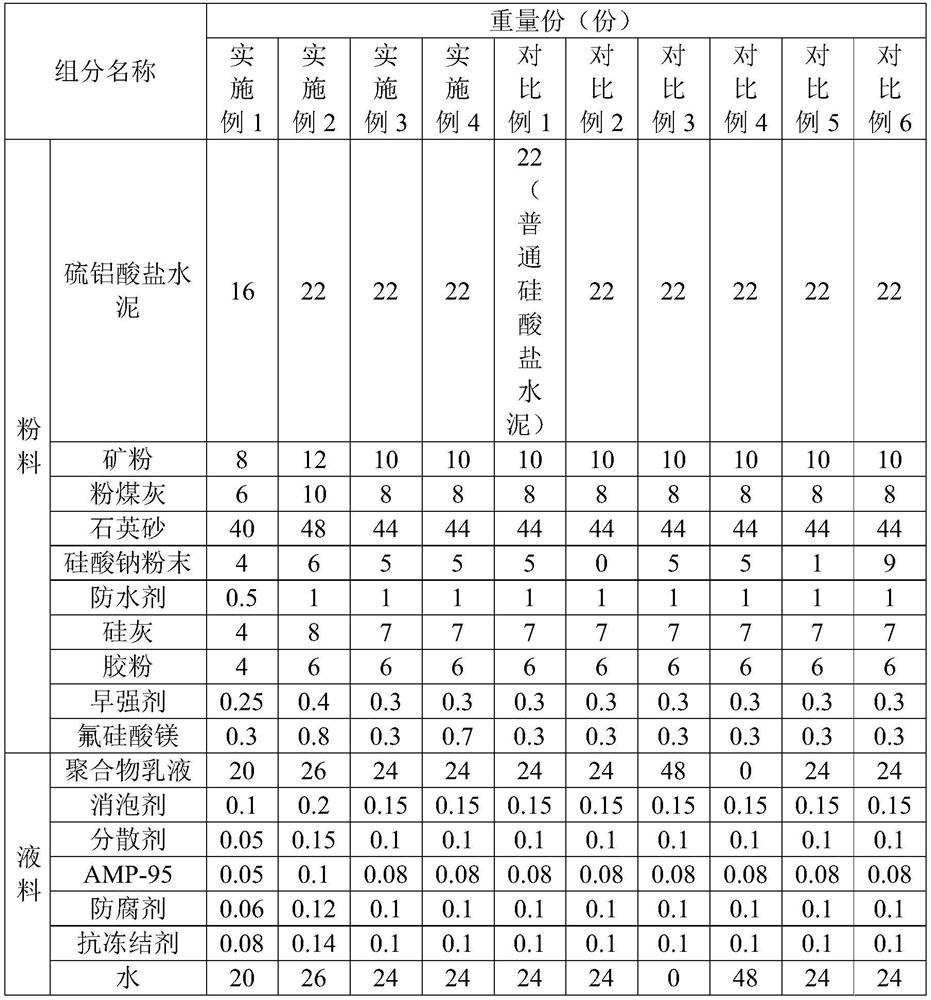

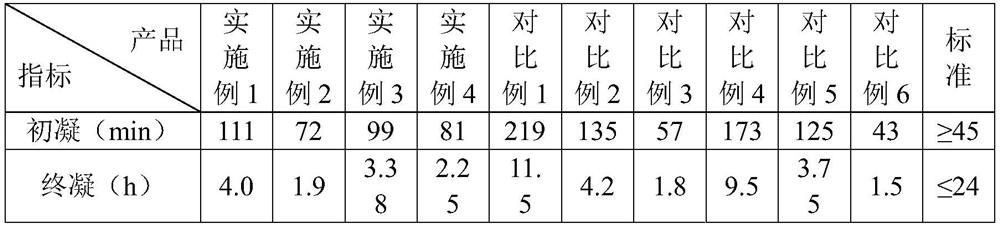

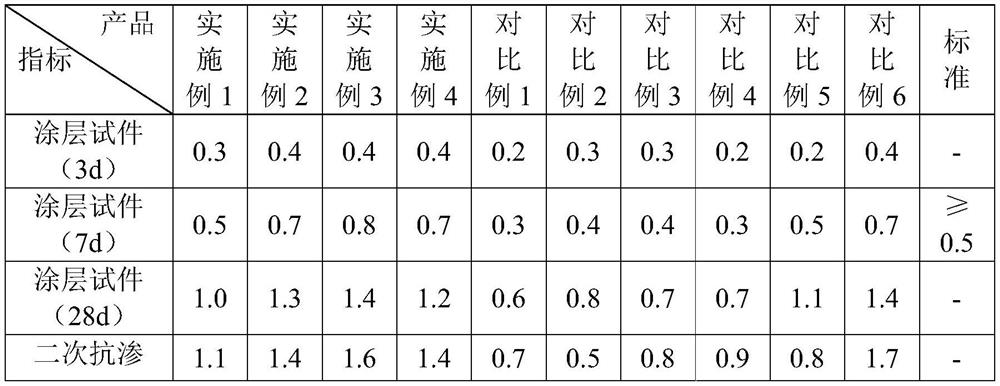

[0055] See Table 1 for specific formulations of backwater waterproof materials that can stop clear water and self-heal.

[0056] Table I

[0057]

[0058] Among them, the sulphoaluminate cement in Examples 1-4 is sulphoaluminate cement 42.5 grade, the ore powder is ultrafine slag powder, silica fume is silicon dioxide ultrafine powder, the rubber powder is acrylic latex powder, fluosilicic acid Magnesium is magnesium hexafluorosilicate powder, early strengthening agent is calcium chloride, water repellent is sodium stearate, polymer emulsion is acrylate copolymer emulsion, defoaming agent is simethicone oil, dispersant is stearamide, The multifunctional additive is AMP-95 multifunctional additive. The antifreeze agent is propylene glycol, the preservative is C15 bactericidal preservative, and the water is deionized water.

[0059] Wherein comparative examples 1~6 are identical with embodiment 3 components, difference is: comparative example 1 is that sulphoaluminate cemen...

Embodiment 5

[0061] The preparation method of Example 5 is the same as that of Example 1, except that the early strengthening agent is calcium formate, and the waterproofing agent is calcium stearate or ammonium stearate.

Embodiment 6

[0063] According to any one of Examples 1-5, each component is weighed according to the formula ratio.

[0064] (1) The powder is weighed according to the formula ratio, and then the sulphoaluminate cement is first added to the powder mixer, and then the mineral powder, quartz sand, sodium silicate, fly ash, waterproofing agent, silica fume , acrylic rubber powder, early strength agent, magnesium fluorosilicate, and then fully stir the mixed powder in the mixer, and finally remove the impurities in the powder mixture through filtration, and the filtered powder can be used to make the water surface waterproof powder of material;

[0065] (2) The liquid material weighs each component according to the formula ratio, and then adds water, defoamer, dispersant, multifunctional auxiliary agent, antifreeze agent, preservative to the reaction kettle in turn, and finally adds polymer propylene milk. The mixed solution is fully stirred evenly in the reaction kettle, and finally the impu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com