A construction method for single side wall formwork support system

A formwork support and support system technology, applied in artificial islands, water conservancy projects, infrastructure engineering, etc., can solve the problems of structural concrete self-waterproof performance, loose joints, large thickness of the structure, etc., to improve the structure Concrete self-waterproof performance, little impact of cross construction, and good pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

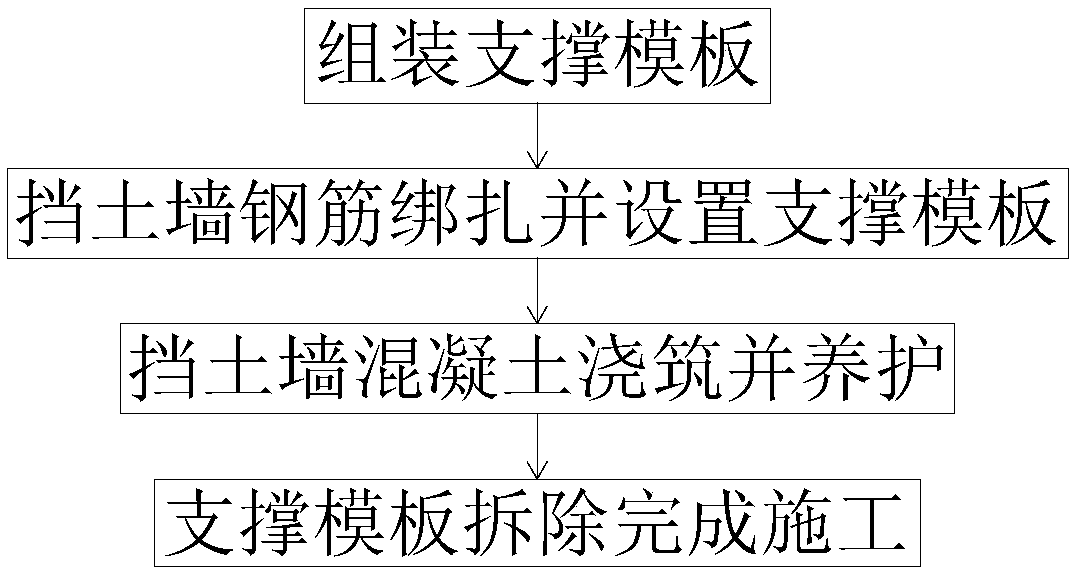

[0048] Such as Figure 1-3 As shown, the construction method for the single side wall formwork support system of the present invention comprises the following steps:

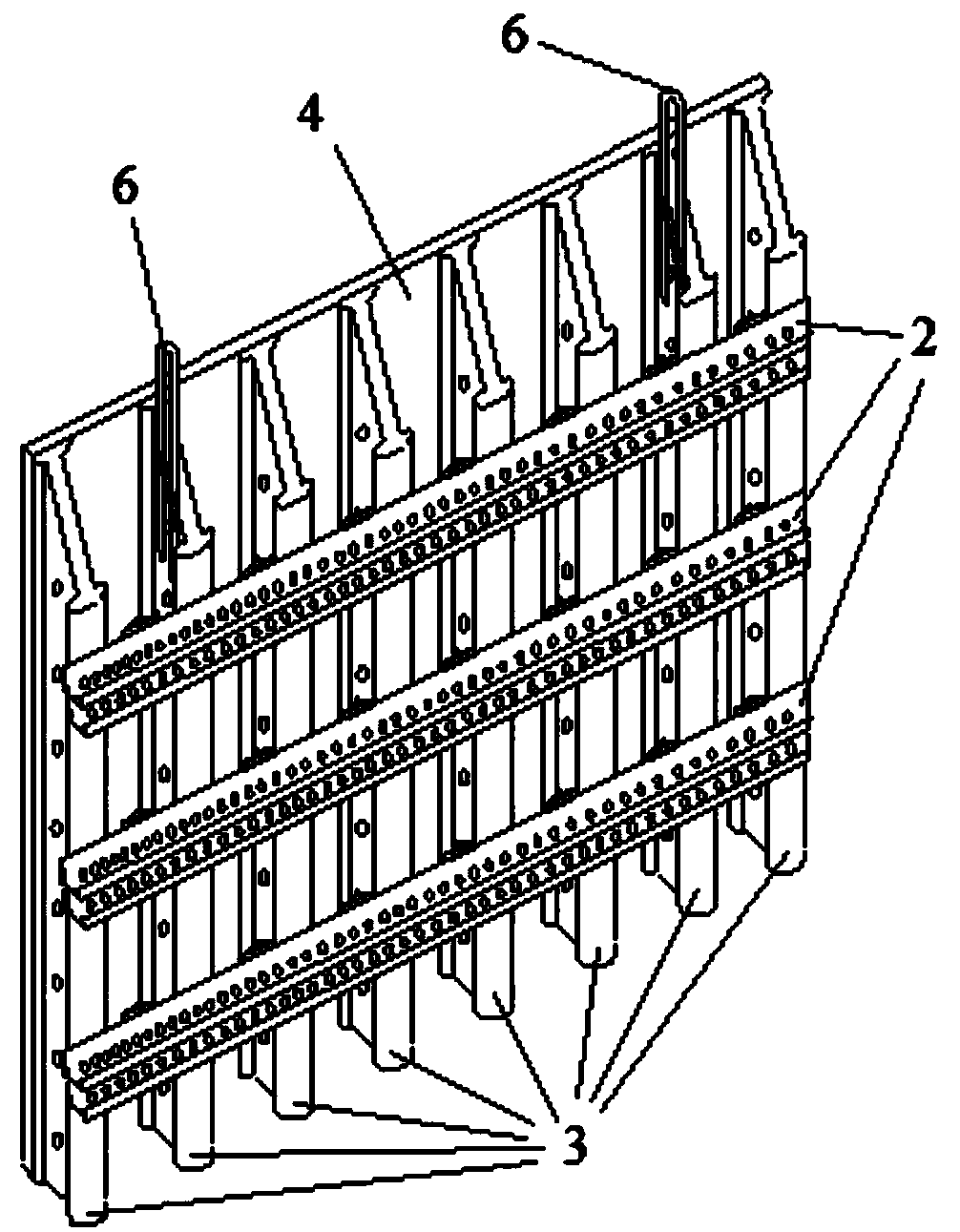

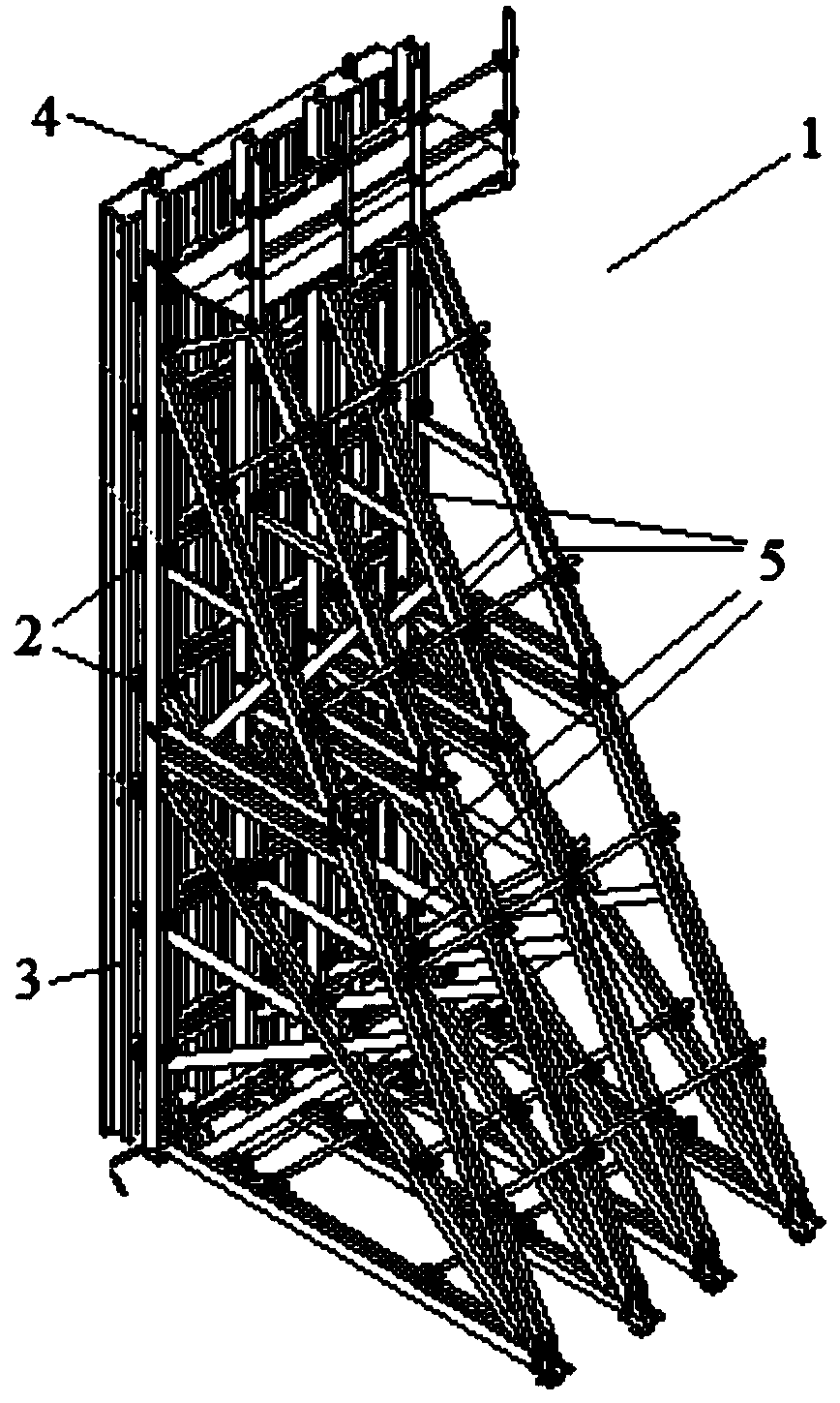

[0049] A, assembling support formwork 1, said support formwork 1 includes horizontal corrugation 2, vertical corrugation 3, panel 4 and single-side support 5, and is assembled into integral structure;

[0050] B. The retaining wall is bound with steel bars, and all the support formworks 1 are arranged on its periphery, and two adjacent support formworks 1 are connected to form a support system, and the support system is fixed relative to the ground;

[0051] C, the concrete pouring of the retaining wall and maintenance;

[0052] D. The supporting formwork 1 is removed to complete the construction.

[0053] As a preferred solution of this embodiment, the assembly of the supporting template 1 in the step A includes the following steps:

[0054] A1, such as figure 2 As shown, all two adjacent horizontal corrugat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com