A kind of shallow buried underground tunnel waterproof construction method

A technology of shallow burial and underground excavation and construction method, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., and can solve problems such as water seepage and affecting the construction quality of comprehensive pipe corridors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] Embodiments of the waterproofing construction method for shallow-buried underground excavation tunnels of the present invention:

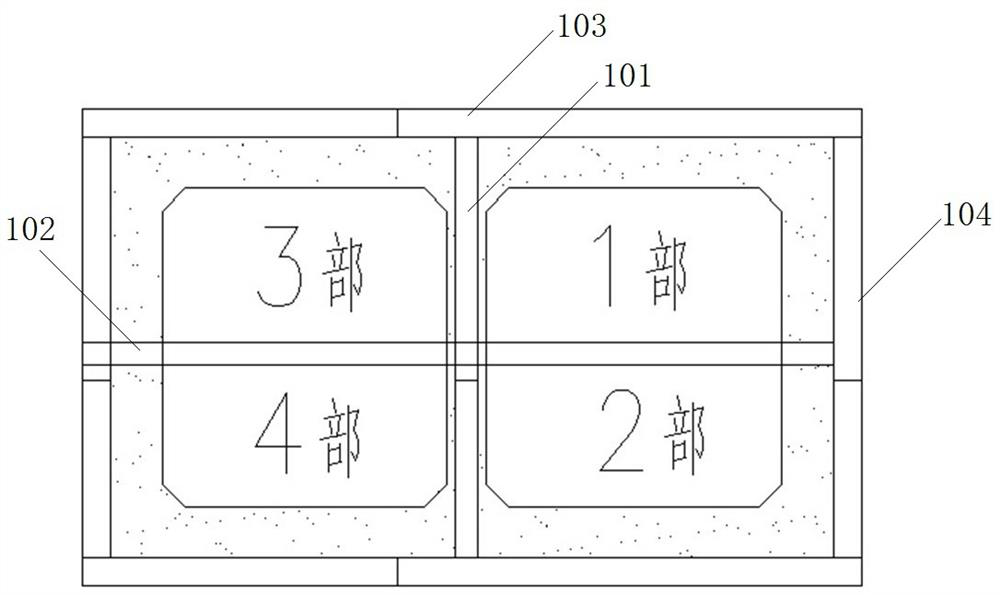

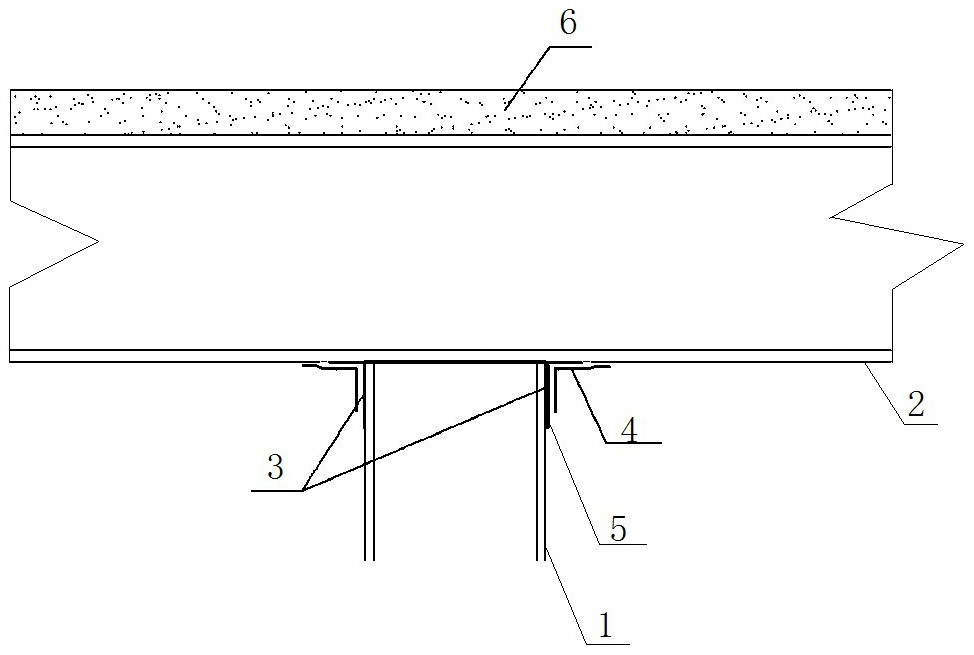

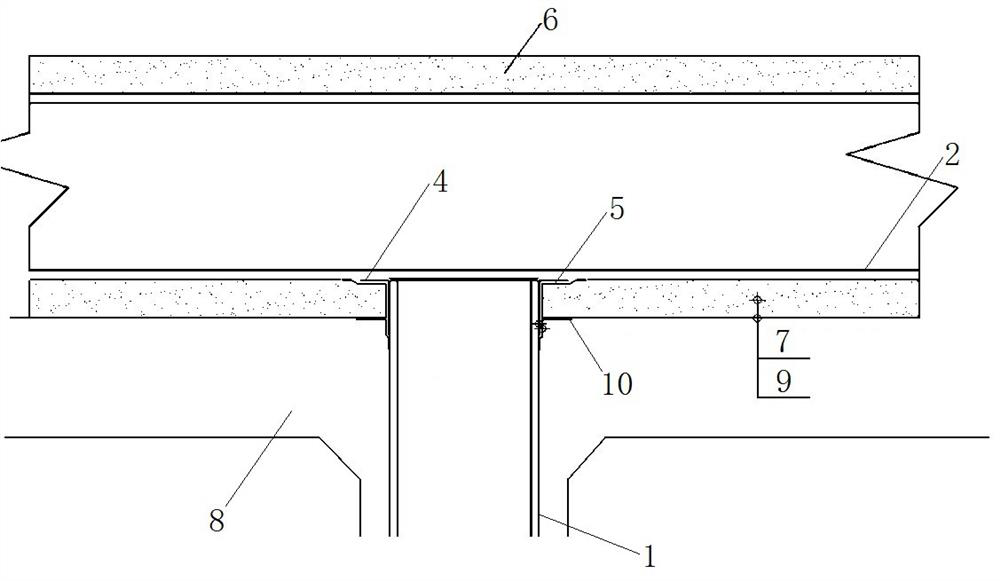

[0028] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 Shown, the waterproof construction method of shallow buried tunnel method of the present invention comprises the following steps:

[0029] Step 1. Spray two layers of two-component polyurethane waterproof coating 3 with a set thickness on the surface of the vertical steel frame 1 before the initial support and respraying of the steel frame for the initial support. The vertical steel frame 1 is installed in the actual project I-shaped steel is used in the middle, and a water stop ring 18 whose shape matches the vertical steel frame 1 is set at the circumferential position of the cross section of the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com