Multi-layer composite waterproof roll material and preparation method thereof

A waterproofing membrane, multi-layer composite technology, applied in the direction of roof covering, building insulation materials, roofs using flexible materials, etc., can solve problems such as overall waterproofing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

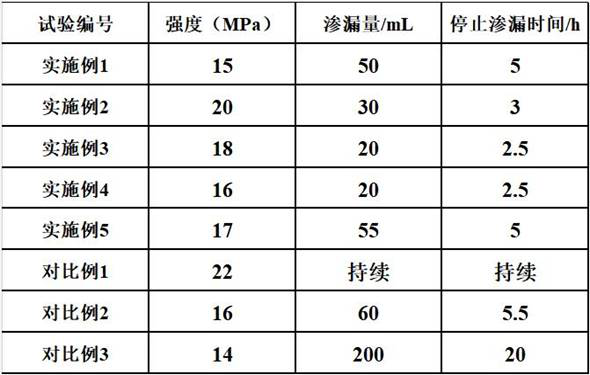

Examples

preparation example Construction

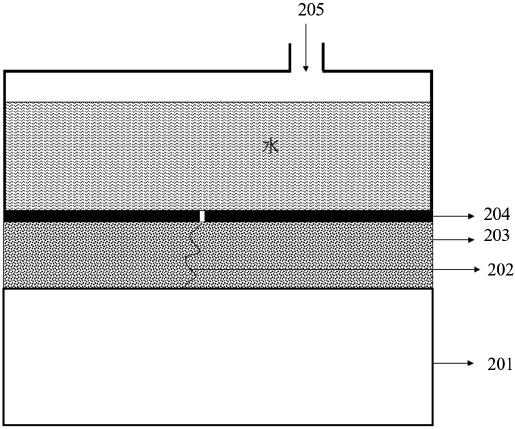

[0090] In one of the more preferred embodiments, the preparation method of the encapsulated material includes the following steps:

[0091] The non-cured asphalt waterproof material is heated to a molten state, and then the osmotic crystalline waterproof microcapsules are added to the non-cured asphalt waterproof material under stirring.

[0092] Compared with solid-solid mixing, solid-liquid mixing is more conducive to increasing the contact area between the non-curing asphalt waterproof material and the osmotic crystalline waterproof microcapsules, so that the osmotic crystalline waterproof microcapsules can be more uniformly dispersed in the non-curable asphalt waterproof material, and further Enhance the waterproof ability of waterproof membrane.

[0093] In one of the more preferred embodiments, the packaging material is at least one selected from polypropylene, polyethylene, ethylene-vinyl acetate copolymer, polyvinyl chloride and ethylene copolymer modified asphalt.

...

Embodiment 1

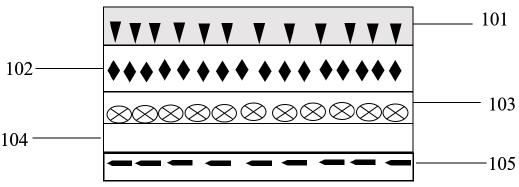

[0125] This embodiment provides a multi-layer composite waterproof roll material and a preparation method thereof, comprising the following steps:

[0126] (1) Preparation of the first supporting protective layer:

[0127] The first supporting protective layer is formed by extrusion molding PE, with a thickness of 0.3mm, and the PE is a non-woven fabric base reinforced PE made of glass fibers;

[0128] (2) Prepare the pressure layer:

[0129] Prepare and form a pressure layer by extrusion encapsulation, in parts by weight, the pressure layer is a water-absorbable swellable layer composed of 80 parts of bentonite composite rubber and 20 parts of water-absorbent resin, with a thickness of 0.5mm;

[0130] (3) Preparation of self-healing layer:

[0131] The self-healing layer includes an encapsulating material and an encapsulated material; wherein the encapsulating material is PE, and the encapsulated material is formed by mixing 99 parts of non-cured asphalt waterproof material...

Embodiment 2

[0142] This embodiment provides a multi-layer composite waterproof roll material and a preparation method thereof, comprising the following steps:

[0143] (1) Preparation of the first supporting protective layer:

[0144] The first supporting protective layer is formed by extrusion molding PP, the thickness of which is 1 mm, and the PP is PP reinforced by a non-woven fabric base composed of basalt fibers;

[0145] (2) Prepare the pressure layer:

[0146] Prepare and form a pressure layer by extrusion encapsulation, in parts by weight, the pressure layer is a water-absorbable swellable layer composed of 80 parts of bentonite composite rubber and 20 parts of water-absorbent resin, with a thickness of 0.8 mm;

[0147] (3) Preparation of self-healing layer:

[0148] The self-healing layer includes an encapsulating material and an encapsulated material; wherein the encapsulating material is PP, and the encapsulated material is mixed by 97 parts of non-cured asphalt waterproof ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com