Rubberized-plasticized non-solidified asphalt paint

An asphalt coating, non-curing technology, applied in asphalt coatings, unspecified rubber coatings, polyester coatings, etc., can solve the problem that the coating loses its waterproof and anti-corrosion function, the coating film is not firmly bonded to the base layer, and affects the use of waterproof coating film effect and other issues, to achieve the effect of improving waterproof effect, good structural deformation followability, and good deformation followability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

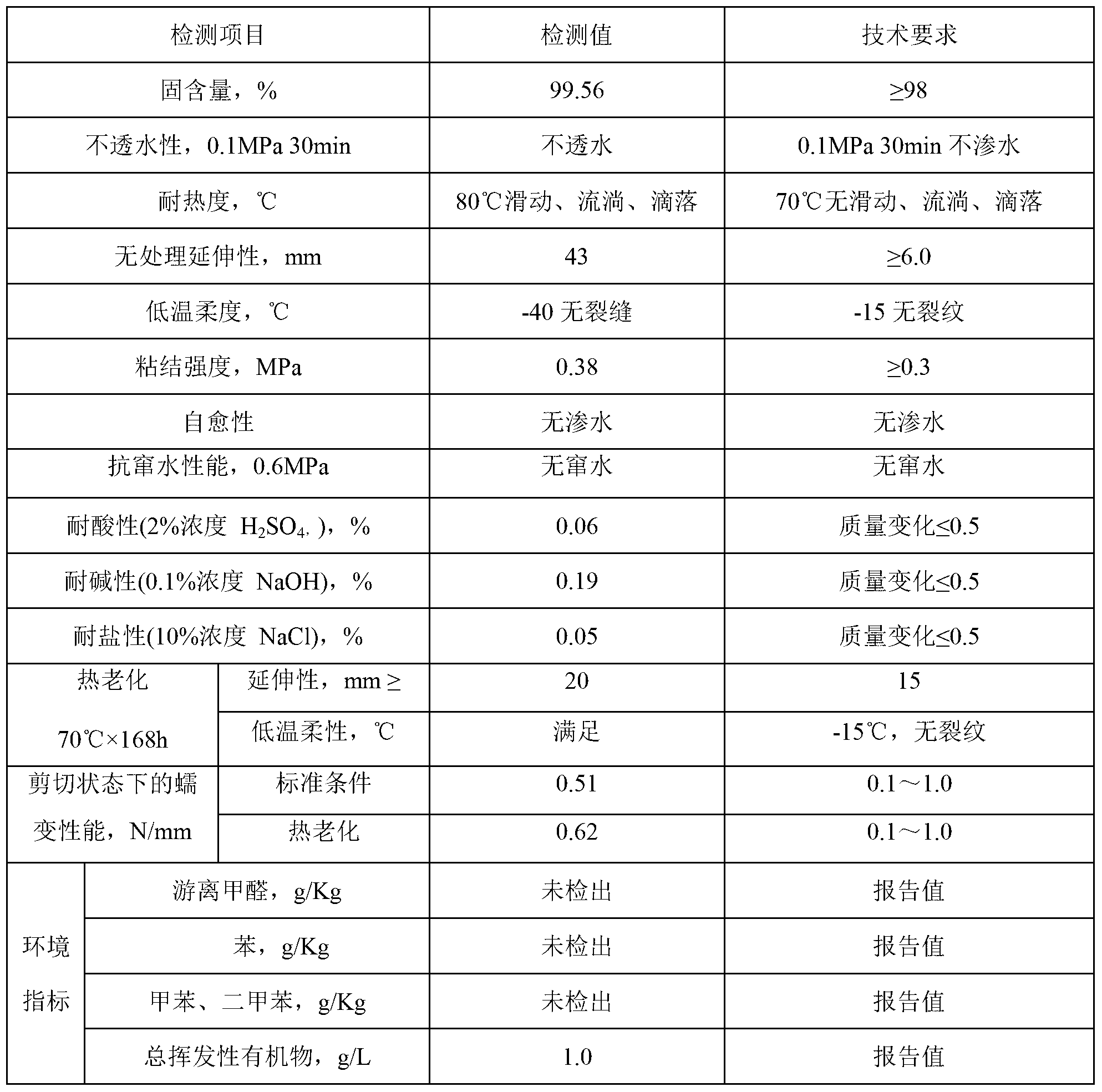

[0020] Embodiment 1: Add 50 parts of petroleum asphalt, 15 parts of rubber oil, 30 parts of 80-mesh waste rubber powder, 10 parts of OP-10, 2 parts of epoxy soybean oil, 6 parts of SBS, 3.5 parts of SBR, and 3.5 parts of PET in sequence , mixed uniformly by high-speed shearing machine at 170-185°C to prepare rubber-plasticized non-curing asphalt coating. According to the 2012 solicitation draft of non-curing rubber asphalt coatings, the technical requirements for creeping asphalt waterproof coatings are tested, see Table 1.

[0021] Table 1 Test results of rubber-plasticized non-curing asphalt coatings

[0022]

[0023] It can be seen from Table 1 that the rubber-plasticized non-curing asphalt coating has high solid content, strong extensibility, and can fully resist the stretching of the base material; it has strong self-healing and water channeling resistance, and has little mass loss in acid, alkali and salt resistance. The material still has no obvious cracks at a low ...

Embodiment approach 2

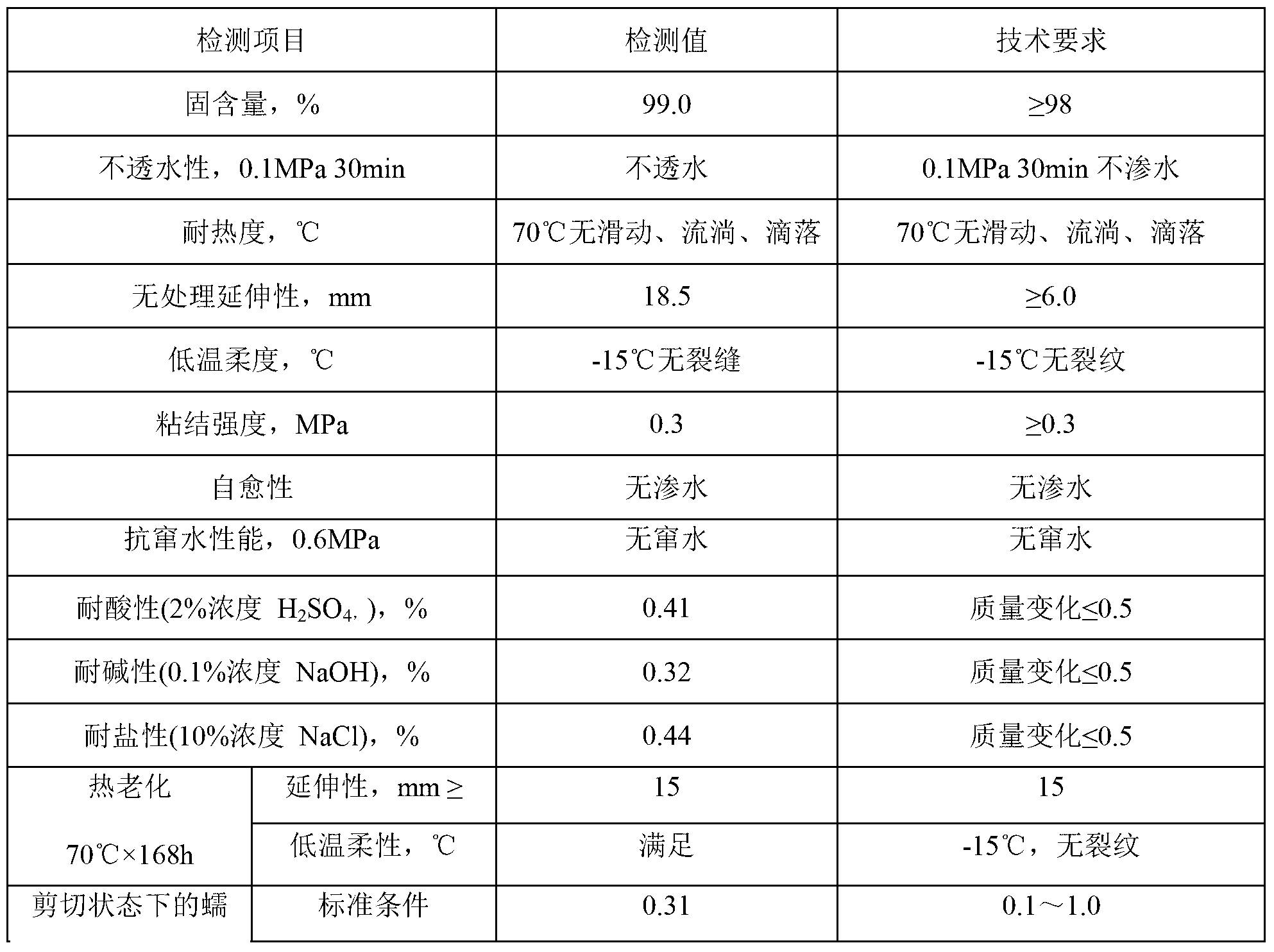

[0026]Embodiment 2: Add 30 parts of petroleum asphalt, 20 parts of rubber oil, 40 parts of 100-mesh waste rubber powder, TX-100.5 parts, 5 parts of fatty acid methyl ester, 2 parts of SBS, 10 parts of SBR, and 2 parts of PBT in sequence, through high-speed shearing The machine mixes uniformly under the condition of 170-185 ℃ to prepare rubber-plasticized non-curing asphalt coating. According to the 2012 solicitation draft of non-curing rubber asphalt coatings, the technical requirements for creeping asphalt waterproof coatings are tested, see Table 2.

[0027] Table 2 Test results of rubber and plastic non-curing asphalt coatings

[0028]

[0029]

Embodiment approach 3

[0030] Embodiment 3: 40 parts of petroleum asphalt, 20 parts of rubber oil, 25 parts of 90 mesh waste rubber powder, 103 parts of NP-10, 0.5 parts of dibutyl phthalate, 10 parts of SBS, 5 parts of SBR, and 10 parts of polyester resin in sequence Add it, and mix it uniformly under the condition of 170-185°C with a high-speed shearing machine to prepare rubber-plasticized non-curing asphalt coating. According to the 2012 solicitation draft of non-curing rubber asphalt coatings, the technical requirements for creeping asphalt waterproof coatings are tested, see Table 3.

[0031] Table 3 Test results of rubber and plastic non-curing asphalt coatings

[0032]

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com