Metal surface anticorrosive coating comprising graphene and preparing method thereof

A metal surface, graphene technology, applied in anti-corrosion coatings, coatings, polyurea/polyurethane coatings, etc., can solve the problems of cumbersome chemical synthesis steps, unsatisfactory self-healing performance, etc., to simplify process steps and enhance self-repair. Restorative effect, easy-to-prepare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

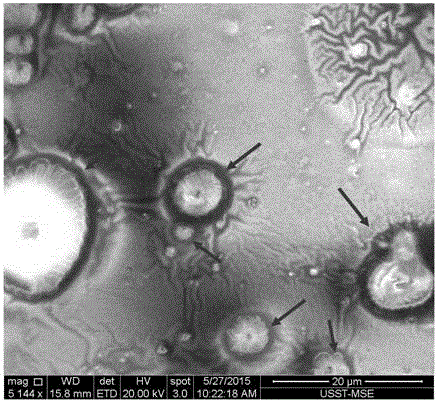

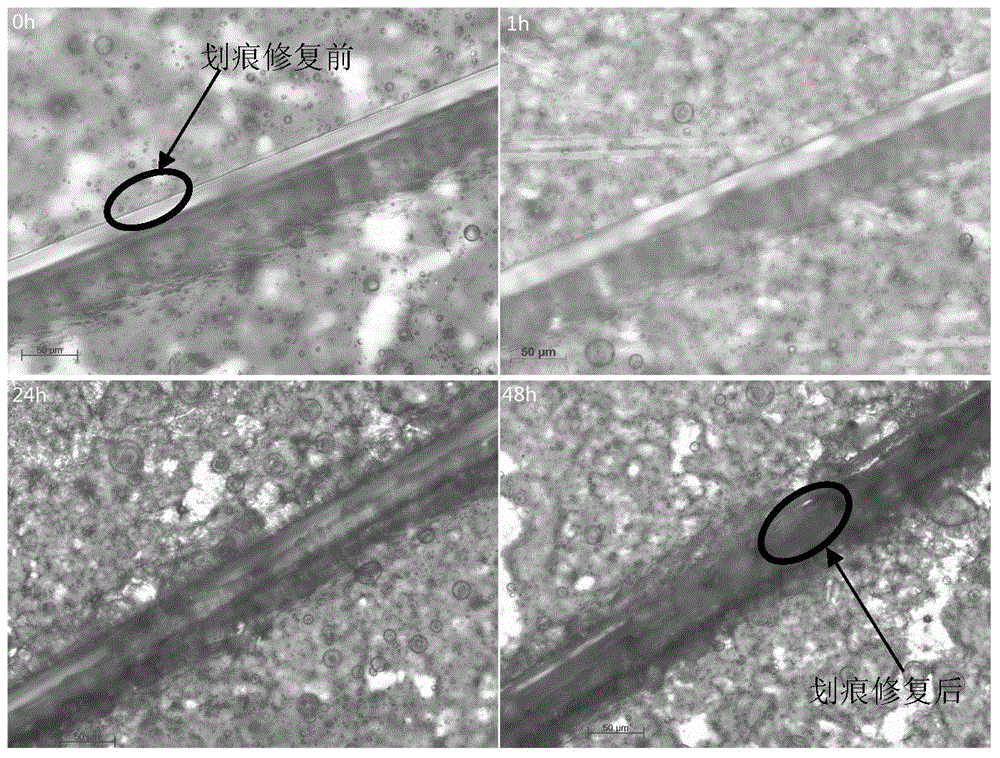

Embodiment 1

[0034] Graphene oxide was prepared by improving Hummer's method, and configured into a graphene oxide aqueous solution with a standard concentration of 2 mg / ml. Graphene (the volume of the above-mentioned graphene oxide aqueous solution multiplied by its standard concentration value, the same below) is mixed with linseed oil at a mass ratio of 0.2%, and deionized water is added to make the water-oil ratio (the ratio of water to linseed oil) mass ratio) is controlled at 2:1. The resulting mixture was dispersed under high shear for 10 minutes, and the rotational speed of the high shear emulsifier was about 600 rpm. Then the mixed solution is mixed with the water-based polyurethane resin, so that the mass ratio of the polyurethane solid content (wherein the actual polyurethane is contained) to the restorative agent linseed oil is 5:1. Adjust the solid content of the paint to 20%, and form a film on the surface of the galvanized steel sheet by a rod coating method. Dry at 110°C ...

Embodiment 2

[0036] Graphene oxide was prepared by improving Hummer's method, and configured as a graphene oxide aqueous solution with a concentration of 2 mg / ml. Graphene and linseed oil are mixed in a mass ratio of 2%, and deionized water is added to control the water-oil ratio at 2:1. Then add a small amount (no more than 0.3 times of graphene mass) of hydrazine hydrate to partially reduce graphene oxide. The mixture was dispersed under high shear for 10 minutes at a speed of about 600 rpm. Then the mixed solution is mixed with water-based polyurethane resin, wherein the mass ratio of polyurethane solid content to repair agent is 20:1. Adjust the solid content of the paint to 20%, and form a film on the surface of the galvanized steel sheet by a rod coating method. Dry at 110°C for 30 minutes.

Embodiment 3

[0038] Graphene oxide was prepared by improving Hummer's method, and configured as a graphene oxide aqueous solution with a concentration of 2 mg / ml. Graphene is mixed with linseed oil by mass ratio of 10%, and deionized water is added to control the water-oil ratio at 20:1. The mixture was dispersed under high shear for 10 minutes at a speed of about 600 rpm. Then the mixed solution is mixed with water-based polyurethane resin, wherein the mass ratio of polyurethane solid content to repair agent is 50:1. Adjust the solid content of the paint to 20%, and form a film on the surface of the galvanized steel sheet by a rod coating method. Dry at 110°C for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com