A kind of self-waterproof concrete and preparation method thereof

A self-waterproof concrete and mixture technology, applied in the field of building materials, can solve the problems of high requirements for concrete waterproofing and inability to meet waterproof concrete, and achieve the effects of improving compactness, improving durability and safety, and improving strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, the preparation of modified wood ceramics

[0035] A. Dry the wood powder to a moisture content of <25%, crush and grind it and pass it through an 80-mesh fine sieve to obtain fine wood powder;

[0036] B takes by weight parts and is 40 parts of liquid epoxy acrylic resins with a solid content of 35 to 45%, 20 parts of liquid silica sol with a solid content of 40 to 50%, and 65 parts of sodium lignosulfonate and stirs to obtain a mixed solution ;

[0037] C. Mix the fine wood powder obtained in step A with the mixed solution obtained in step B evenly in a weight ratio of 1:1.2, impregnate at normal temperature and pressure for 65 hours, dry, put in an inert gas-protected heating furnace for preheating, and gradually increase the temperature to 600°C, depressurize and extract the low molecular components, then continue to heat up to 1500°C, vacuum carbonize for 4 hours, and cool to obtain the product.

Embodiment 2

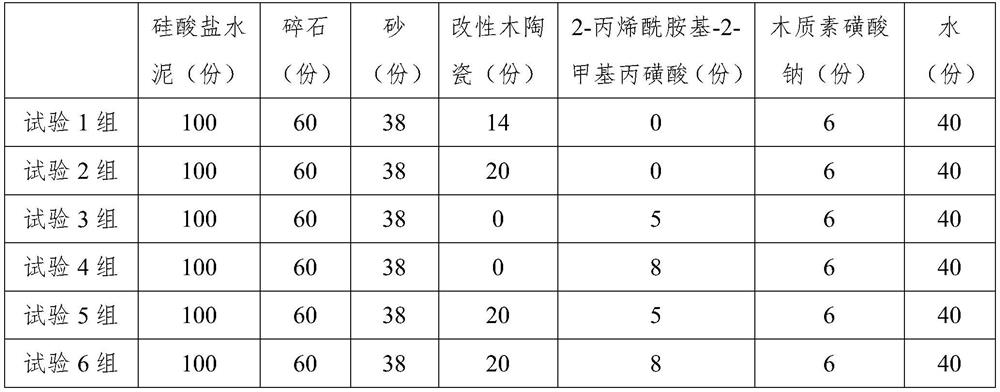

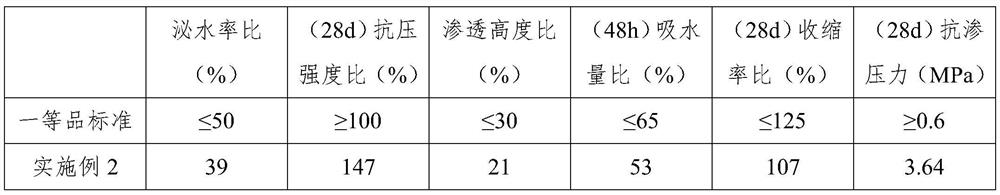

[0038] Embodiment 2, a kind of self-waterproof concrete

[0039] The self-waterproof concrete consists of the following components and parts by weight thereof:

[0040] 80 parts of Portland cement, 55 parts of gravel, 35 parts of sand powder, 10 parts of modified wood ceramics, 4 parts of 2-acrylamido-2-methylpropanesulfonic acid, sodium lignosulfonate with a molecular weight of 10,000-50,000 5 parts and 28 parts of water; the particle size of the gravel is 10-20mm, the mud content is less than 0.5%, and the needle-like particles are less than 10%; the fineness modulus of the sand is 2.6-3.0, and the mud content Less than 2%; the modified wood ceramics is the modified wood ceramics prepared in Example 1.

[0041] Preparation:

[0042] S1 Pour crushed stone, Portland cement, and sand into the hopper in sequence, and stir for 40-60 seconds to obtain mixture I;

[0043] S2 Stir 2-acrylamido-2-methylpropanesulfonic acid, modified wood ceramics, and sodium lignosulfonate evenly ...

Embodiment 3

[0045] Embodiment 3, a kind of self-waterproof concrete

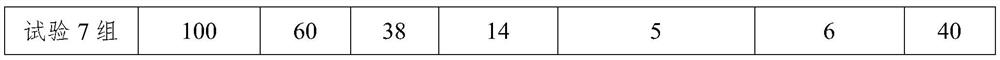

[0046] The self-waterproof concrete consists of the following components and parts by weight thereof:

[0047] 100 parts of Portland cement, 60 parts of gravel, 38 parts of sand, 14 parts of modified wood ceramics, 5 parts of 2-acrylamido-2-methylpropanesulfonic acid, sodium lignosulfonate with a molecular weight of 10,000-50,000 6 parts and 40 parts of water; the particle size of the gravel is 10-20mm, the mud content is less than 0.5%, and the needle-like particles are less than 10%; the fineness modulus of the sand is 2.6-3.0, and the mud content Less than 2%; the modified wood ceramics is the modified wood ceramics prepared in Example 1.

[0048] The preparation method is similar to Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com