Automatic push-pull fluff adsorption device for textile wastewater treatment

A technology of textile wastewater and adsorption device, which is applied in the direction of adsorption water/sewage treatment, etc., can solve the problems of reduced treatment efficiency, limited adsorption range of adsorption plates, troublesome delivery, etc., and achieves the effect of ensuring the expansion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

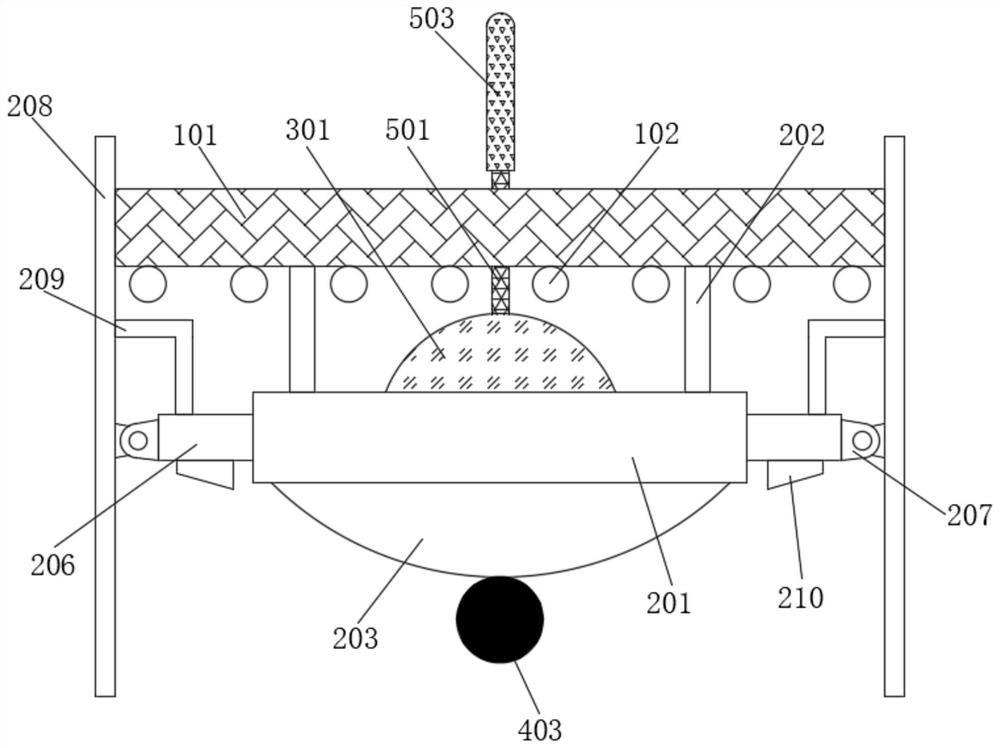

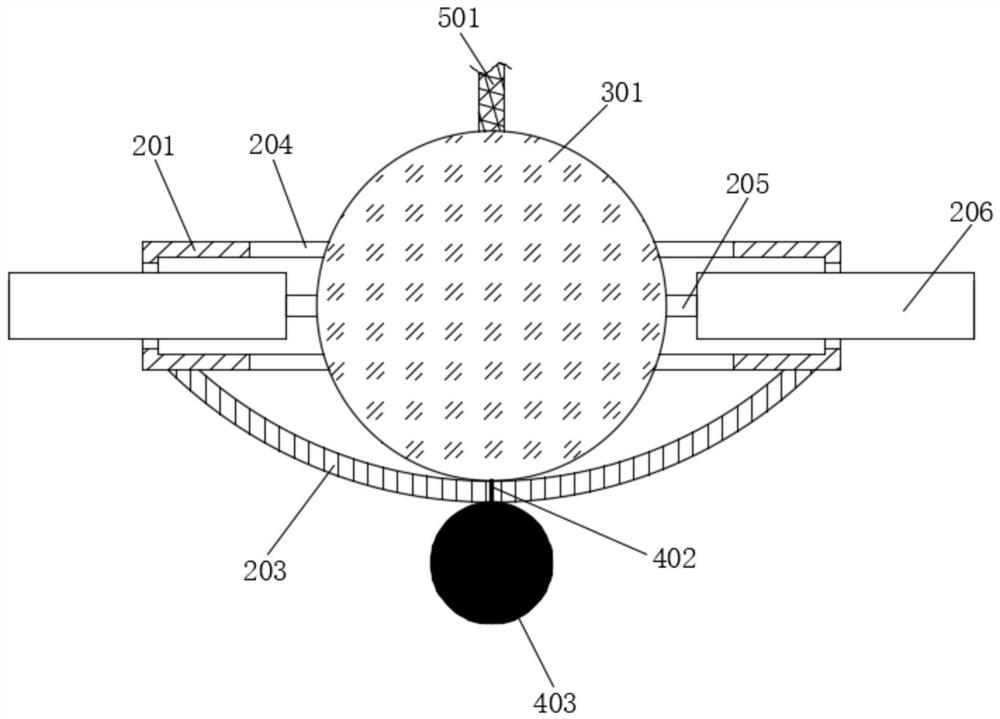

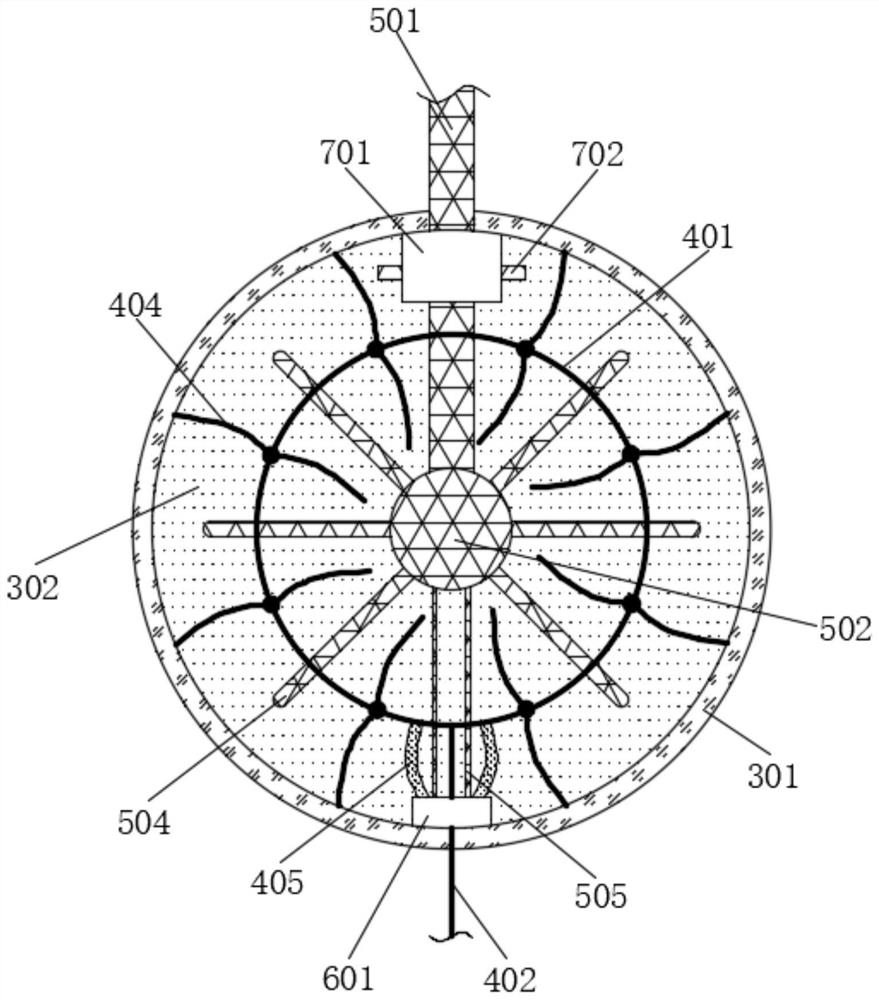

[0041] see Figure 1-2 , an automatic push-pull fluff adsorption device for textile wastewater treatment, comprising an adsorption plate 101 and a device box 201, the device box 201 is located below the adsorption plate 101, and the top of the device box 201 is fixedly connected with two symmetrically arranged connecting rods 202, the end of the connecting rod 202 away from the device box 201 is fixedly connected to the adsorption plate 101, the device box 201 and the adsorption plate 101 are connected and fixed through the connecting rod 202, and the bottom end of the adsorption plate 101 is fixedly connected with a plurality of floating balls distributed in a rectangular array 102. When in use, put the device into textile sewage, the adsorption plate 101 can float on the water surface under the action of the floating ball 102, and absorb the surrounding fluff, and the bottom of the device box 201 is fixedly connected with a hemispherical shell base 203 The inside of the devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com