A low-shrinkage, crack-resistant C60 grade self-compacting bridge tower concrete based on internal curing, shrinkage compensation and toughening and its preparation method

A technology of compensating shrinkage and low shrinkage resistance, applied in the field of building materials, can solve the problems of limited cement dispersing ability, lack of compensating shrinkage effect, and large thermal insulation temperature rise of concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

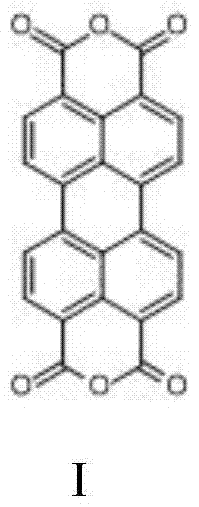

Image

Examples

Embodiment 1

[0044]The preparation method of the ultra-dispersed water-reducing, shrink-reducing and plastic-preserving admixture in embodiment 1 is roughly the same as embodiment 2~4, difference is: 1) the molar ratio of methallyl alcohol, ammoniacal liquor and propylene oxide is 1:0.4: 20. The amount of catalyst used is 0.4% of the mass of methallyl alcohol, the reaction pressure is 0.30MPaG, the temperature is 105°C, and the time is 5h; 2) the reaction between methallyl alcohol polyoxypropylene ether and triisopropanolamine Mixture 86%, sodium acrylate sulfonate 3%, methacrylate 8%, water 3%; 3) The molar ratio of methacrylic acid and polypropylene glycol monomethyl ether is 1.18:1, dipropylene glycol monobutyl ether and maleic anhydride The molar ratio is 1.5:1, the reaction temperature is 120°C, and the time is 4h; 4) Polypropylene glycol monomethyl ether methacrylate monomer 82%, diethylene glycol dipropylene glycol monobutyl ether monomer 3%, methyl Acrylic acid 8%, dimethylaminoeth...

Embodiment 2

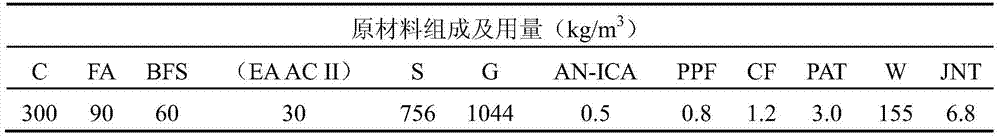

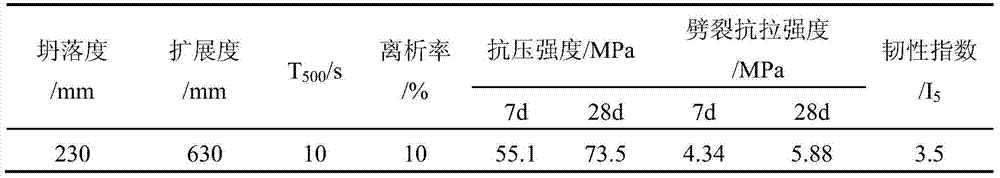

[0059] A low-shrinkage crack-resistant C60 grade self-compacting bridge tower concrete based on internal curing, shrinkage compensation and toughening, the preparation process of which includes the following steps:

[0060] 1) Accurately weigh cement (C), fly ash (FA), slag powder (BFS), expansion agent (EA AC II, limit expansion rate in 7d water to 0.08%), river sand according to the ratio of raw materials listed in Table 4 (S), gravel (G), AN-ICA internal curing agent (AN-ICA), polyacrylonitrile fiber (PPF), micron modified absorbent cotton cellulose (CF), cement paste microstructure regulator (PAT ), water (W) and ultra-dispersed water-reducing, shrink-reducing and plastic-preserving admixture (JNT);

[0061] 2) Add the weighed cement, fly ash, mineral powder, expansion agent, AN-ICA internal curing agent, cement slurry microstructure regulator, gravel, and river sand into a single-horizontal shaft forced mixer for dry mixing In the process of dry mixing, add the weighed p...

Embodiment 3

[0071] A low-shrinkage crack-resistant C60 grade self-compacting bridge tower concrete based on internal curing, shrinkage compensation and toughening, the preparation process of which includes the following steps:

[0072] 1) Accurately weigh cement (C), fly ash (FA), slag powder (BFS), expansion agent (EA AC II, limit expansion rate in 7d water: 0.08%), river sand according to the ratio of raw materials listed in Table 7 (S), gravel (G), AN-ICA internal curing agent (AN-ICA), polyacrylonitrile fiber (PPF), micron modified absorbent cotton cellulose (CF), cement paste microstructure regulator (PAT ), water (W) and ultra-dispersed water-reducing, shrink-reducing and plastic-preserving admixture (JNT);

[0073] 2) Add the weighed cement, fly ash, mineral powder, expansion agent, AN-ICA internal curing agent, cement slurry microstructure regulator, gravel, and river sand into a single-horizontal shaft forced mixer for dry mixing In the process of dry mixing, add the weighed pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com