Film expansion machine and process for laser cutting by employing same

A technology of laser cutting and film expanding machine, which is applied in the direction of laser welding equipment, manufacturing tools, metal processing equipment, etc. It can solve the problems that the expansion range cannot meet the demand, the structure of the film expanding machine is complicated, and the production efficiency is low, and the cutting process steps can be achieved. Reasonable, good film expansion quality, cutting efficiency and cutting quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

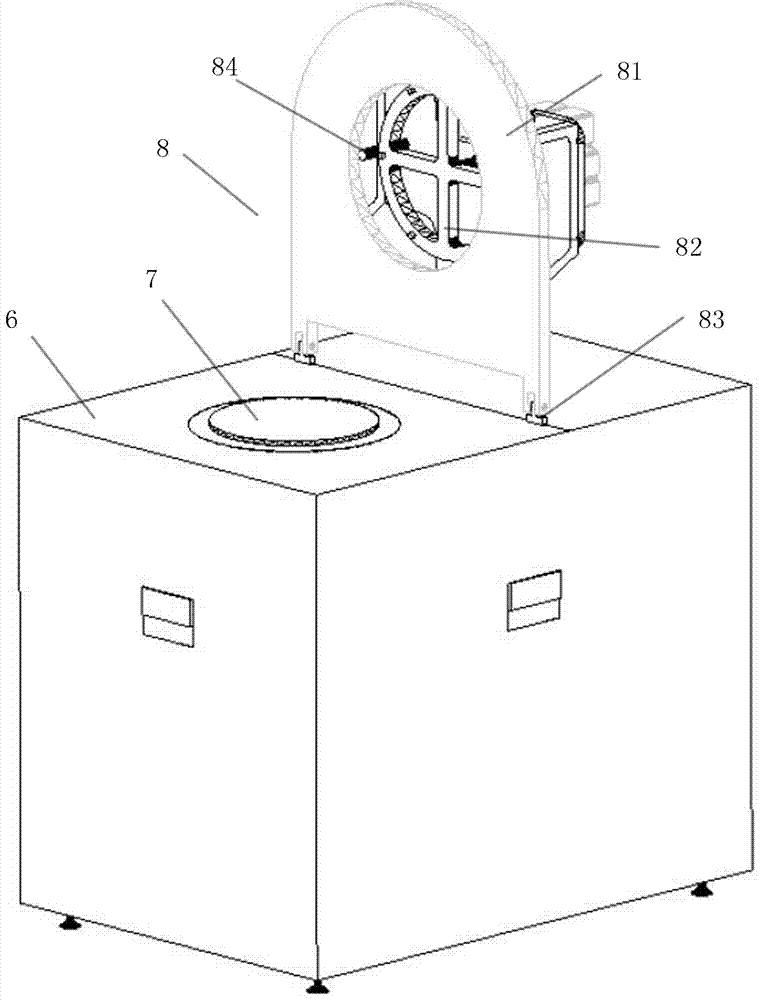

[0036] like figure 1 Shown, a kind of expanding film machine comprises:

[0037] A working platform, on which there is an expanding film base that can be raised and lowered relative to the working platform; specifically, the expanding film base is connected with a lifting mechanism such as a cylinder;

[0038] Cover body, the cover body is opened and closed relative to the film expansion base, the cover body includes a cover body and a sub-cover body, the cover body has a through hole opened relative to the film expansion base, the sub-cover body is arranged relative to the film expansion base, and the sub-cover body can Pass through the through hole to contact with the expansion film base; specifically, a number of guide columns are arranged between the sub-cover body and the cover body along the circumferential direction, and the sub-cover body is connected with a power device, which is a lifting cylinder in this embodiment.

[0039] The sub ring and the mother ring, the su...

Embodiment 2

[0044] The process of cutting by using the film expander in embodiment 1, wherein, in order to match the shape of the processing component, the film expander base, the through hole and the sub-cover are all circular. The process includes steps:

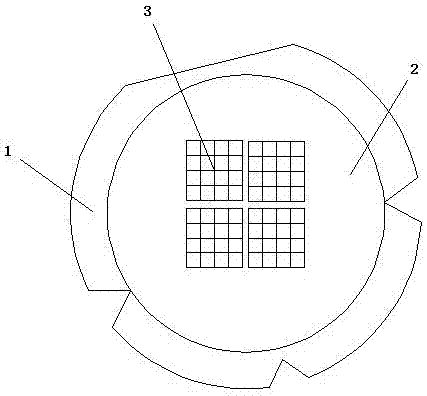

[0045] (1) Attach four middle pieces in the middle of the front of the film, and the number of middle pieces can be adjusted arbitrarily according to needs. Then attach the first wafer ring to the front of the film along the periphery of the film to form a sheet component;

[0046] (2) Put the sheet assembly into the laser cutting machine, and then use the laser beam to cut the middle sheet into several small pieces; specifically, rectangular small pieces of uniform size; such as figure 2 as shown,

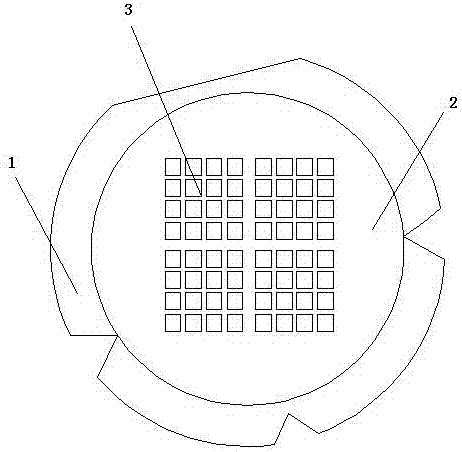

[0047] (3) Take out the sheet assembly and put it into the expansion machine to expand the film, such as image 3 Shown:

[0048] (3-1) Place the sub-ring on the expansion film base, place the mother ring on the sub-cover, then heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com