Viscosity-reducing enhanced anti-cracking agent and preparation method thereof

An enhanced, anti-cracking agent technology, applied in the field of concrete admixtures for building materials, can solve the problems of reducing the viscosity of concrete, increasing the cost of concrete production, and the fact that the viscosity reducer does not have the ability to compensate for concrete shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

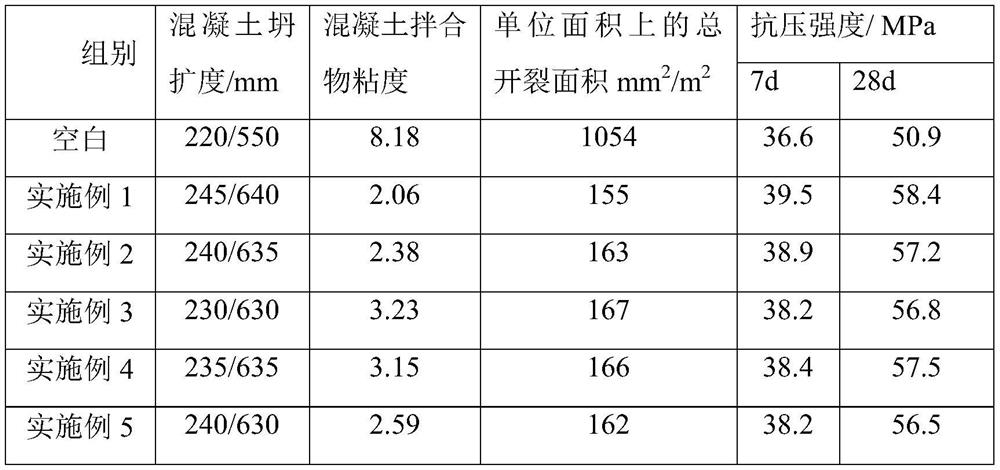

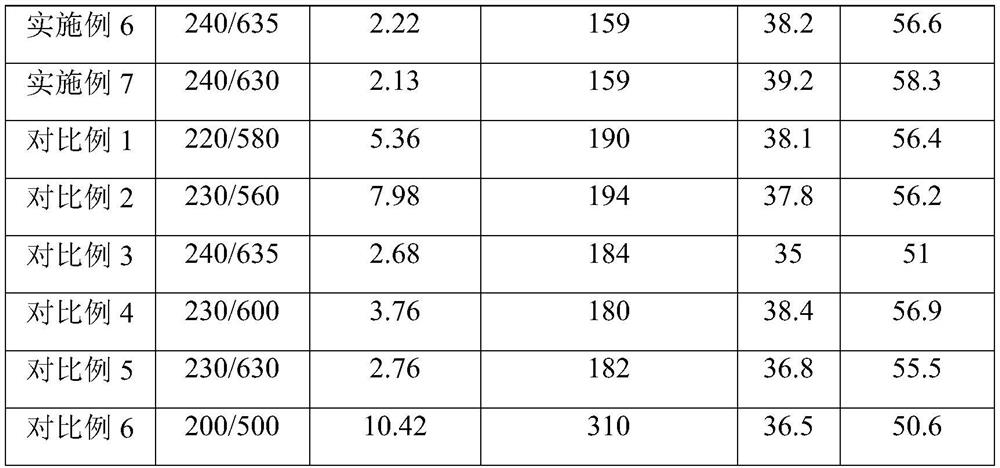

Examples

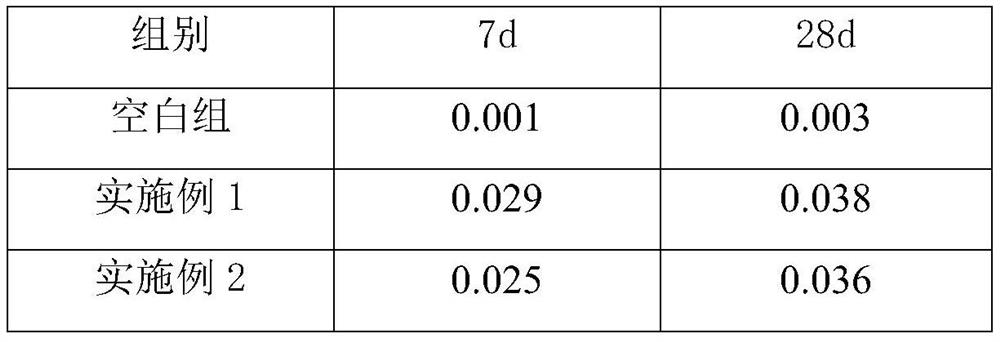

Embodiment 1

[0029] The viscosity-reducing enhanced anti-crack agent provided in this example is made of the following raw materials in mass percentage: 40% of modified magnesium oxide expansion agent, 10% of polypropylene fiber, 20% of viscosity-reducing component, and 30% of reinforcing component; The viscosity-reducing component includes the following components in mass percentage: 45% of microbead powder, 2% of cellulose ether, 5% of powder water reducer, and 48% of sepiolite; the reinforcing component includes the following mass percentage Each component of: superfine mineral admixture 60%, silica fume 20%, nano silicon dioxide 10%, sodium gluconate 2%, urea 8%; The ultrafine mineral admixture is superfine fly ash and superfine mineral powder, the mass ratio of the two is 60:40; the fineness is 750m 2 / kg.

[0030] The preparation method of the modified magnesium oxide expansion agent is as follows: the magnesium oxide expansion clinker is mixed with polymethylsiloxane, ground and dr...

Embodiment 2

[0038] This example is basically the same as Example 1, except that the viscosity-reducing enhanced anti-cracking agent is made of the following raw materials in mass percentage: 30% of modified magnesium oxide expansion agent, 15% of polypropylene fiber, and 20% component, 35% reinforcing component.

Embodiment 3

[0040] This example is basically the same as Example 1, except that the viscosity-reducing enhanced anti-cracking agent is made of the following raw materials in mass percentage: 50% of modified magnesium oxide expansion agent, 5% of polypropylene fiber, and 20% component, 25% reinforcing component.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com