Adamantyl contained hydrophobic association zwitter-ion starch and preparation method thereof

A technology of adamantyl and zwitterions, applied in the field of functional polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Add 60g of acrylamide, 30g of sodium acrylate and 15g of dimethyl diallyl ammonium chloride into the reactor, stir evenly, adjust the pH value of the system to 7.5 with a NaOH solution with a concentration of 5.0% by mass, Add 300 mL of distilled water.

[0043] Add 20.0g sodium dodecylsulfonate in the reactor, add 1.5g (NH 4 ) 2 S 2 o 8and 0.5g NaHSO 3 , and reacted at a temperature of 50°C for 12.0 hours to obtain a colorless and transparent gum-like crude product.

[0044] Add 1000mL of absolute ethanol to precipitate and filter, wash the product three times with absolute ethanol and acetone successively, and then use the glacial acetic acid-ethylene glycol mixed solvent with a volume ratio of 3:2 as the extraction agent to extract the product with Soxhlet Extracted for 24 hours, vacuum-dried to constant weight at 25°C to obtain hydrophobically associated amphoteric ion starch, its relative molecular mass is 15860000, and its molecular structure is as follows: ...

Embodiment 2

[0049] Add 40g of acrylamide, 20g of sodium acrylate and 10g of dimethyl diallyl ammonium chloride into the reactor, stir evenly, and adjust the pH value of the system to 8.0 with a NaOH solution with a concentration of 5.0% by mass. Supplement with 388 mL of distilled water.

[0050] Add 30.0g sodium octadecylbenzenesulfonate to the reactor, stir well and add 2.0g K 2 S 2 o 8 and 0.75g NaHSO 3 , reacted at a temperature of 45° C. for 10.0 hours to obtain a colorless and transparent gum-like crude product.

[0051] Add 1000mL of absolute ethanol to precipitate and filter, wash the product three times with absolute ethanol and acetone successively, and then use the glacial acetic acid-ethylene glycol mixed solvent with a volume ratio of 3:2 as the extraction agent to extract the product with Soxhlet After extracting for 24 hours, vacuum drying at 25°C to constant weight, the hydrophobically associated zwitterionic starch was obtained, with a relative molecular mass of 16070...

Embodiment 3

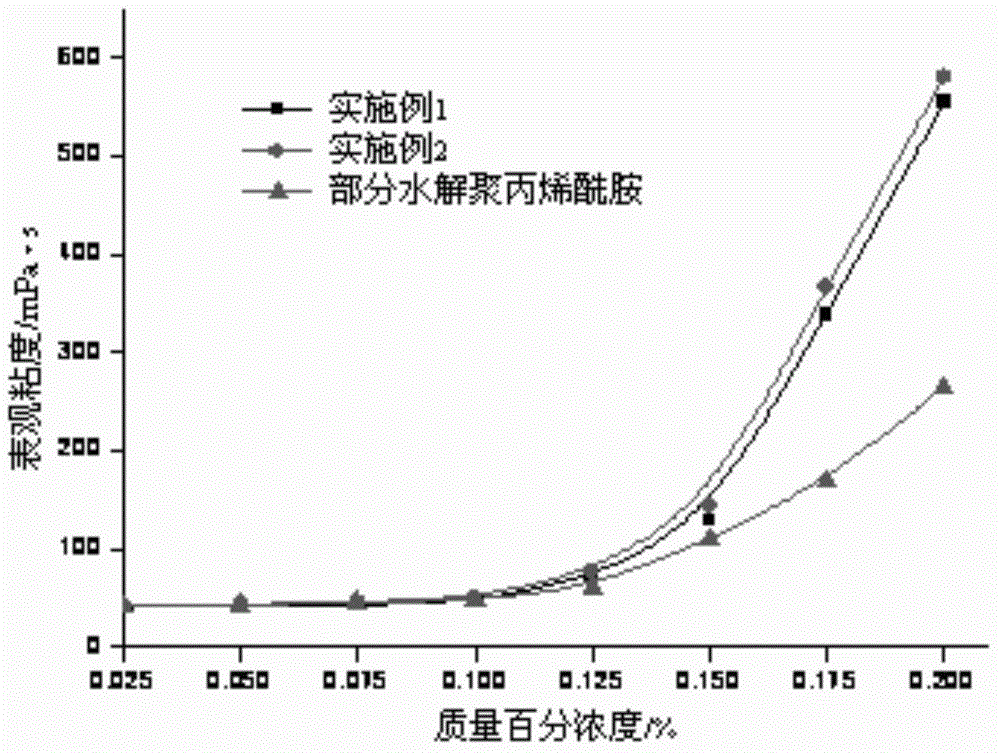

[0056] From the above results, it can be seen that compared with partially hydrolyzed polyacrylamide, the apparent viscosity of the hydrophobically associated zwitterionic starch obtained in Examples 1 and 2 increases sharply when the mass percentage concentration is greater than 0.125%, while partially hydrolyzed polyacrylamide The apparent viscosity increase rate of acrylamide is relatively slow, indicating that hydrophobic associations have occurred between the hydrophobically associated zwitterionic starch molecules obtained in Examples 1 and 2 to form a physical cross-linked network structure, making the apparent viscosity of the solution rapidly increased.

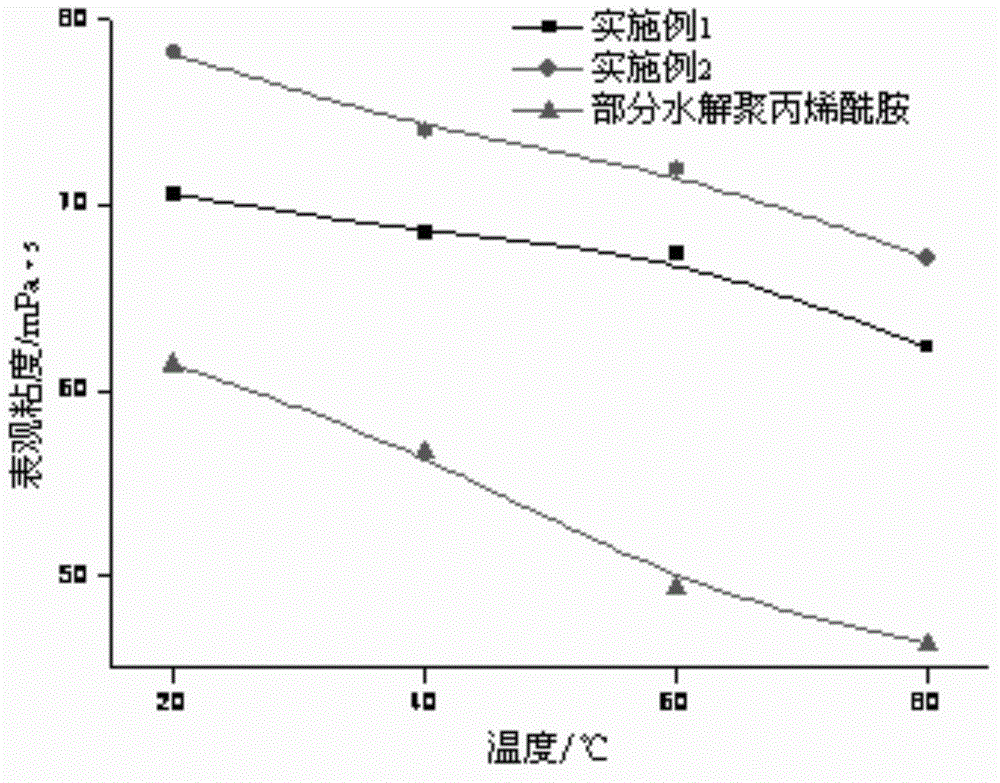

[0057] Example 4

[0058] Effect of Temperature on Apparent Viscosity of Hydrophobically Associated Zwitterionic Starches

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com