A temperature-resistant and salt-resistant hydrophobic association polymer oil displacement agent and its preparation method

A hydrophobic association, temperature-resistant and salt-resistant technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of polymer long-term stability to be strengthened, low viscosity retention rate, etc., to achieve low production cost, Good salt resistance, good temperature resistance and shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the preparation of monomer NAPA

[0026] Add 1.63g allylamine, 4.00g triethylamine and 0.02g hydroquinone to a 150ml dry single-necked flask, dilute with dichloromethane solvent, and slowly dissolve the mixture with a constant pressure dropping funnel under ice bath and magnetic stirring 4. Add 41g of phenylacetyl chloride dropwise into the reactor, and control the dropping within half an hour; after the dropping, react at room temperature for 6 hours, and the reaction solution is washed with water, acid, alkali, saturated salt water, dried and filtered, and the solvent is evaporated to obtain a white Solid powder NAPA monomer with a yield of 99.8%.

Embodiment 2

[0027] Embodiment 2: the preparation of polymer AM / NaAA / NAPA / AHAC

[0028] Add the NAPA and AHAC prepared above into a 150ml three-necked flask according to the ratio in Table 1, then add OP-10 emulsifier and 10g deionized water, stir well at 30°C until the emulsification is complete; then weigh 10g of AA Dilute with deionized water, slowly add sodium hydroxide in an ice bath, stir and cool to room temperature; then add AM and NaAA to the flask, adjust the pH to 7 with 20% NaOH solution, and pass nitrogen for 20 minutes; then add the initiator bisulfite Add sodium solution, then add ammonium persulfate solution, pass nitrogen gas for 10 minutes, and react at a temperature of 40°C for 12 hours; finally wash with absolute ethanol until the polymer is completely precipitated, then pulverize the polymer, and dry at a constant temperature of 40°C to obtain AM / NaAA / NAPA / AHAC quaternary polymer.

[0029] Table 1 Quaternary polymer synthesis drug dosage

[0030]

Embodiment 3

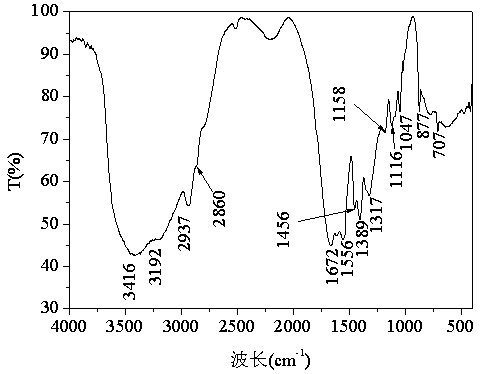

[0031] Embodiment 3: polymer AM / NaAA / NAPA / AHAC terpolymer structural characterization

[0032] The infrared spectrogram of the tetrapolymer AM / NaAA / NAPA / AHAC synthesized by embodiment 2 is as follows figure 1 shown. From the figure, we know that 3416cm -1 The strong and broad absorption peak is attributed to the stretching vibration of -OH; 1456cm -1 The absorption peak at is due to -CH 3 The asymmetric in-plane bending vibration and -CH 2 -caused by the scissor vibration, 1389cm -1 The absorption peak at is due to -CH 3 caused by bending vibrations in the symmetric plane, while at 2937cm -1 and 2860cm -1 Two peaks appear, these all prove the existence of methyl group and methylene group; 3192cm -1 The strong absorption peak attributable to the N-H stretching vibration, 1672cm -1 The absorption peak at is attributed to -C=O stretching vibration, and these two peaks combine to confirm the existence of the amide structure; 1556cm -1 Stretching vibrations attributed to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com