A kind of hydrophobic association zwitterionic polymer and preparation method thereof

A technology of amphoteric ion and hydrophobic association, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor thermal stability and biological stability, high cost, sudden change of solution performance, etc., to facilitate industrial production , Low production cost, strong viscosity increasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

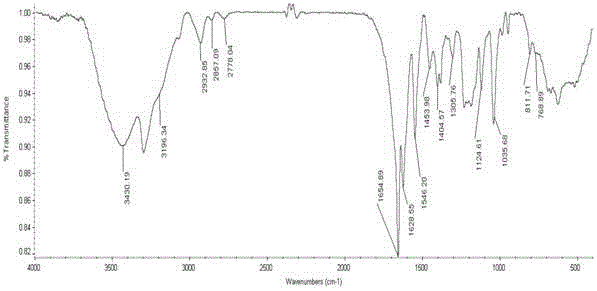

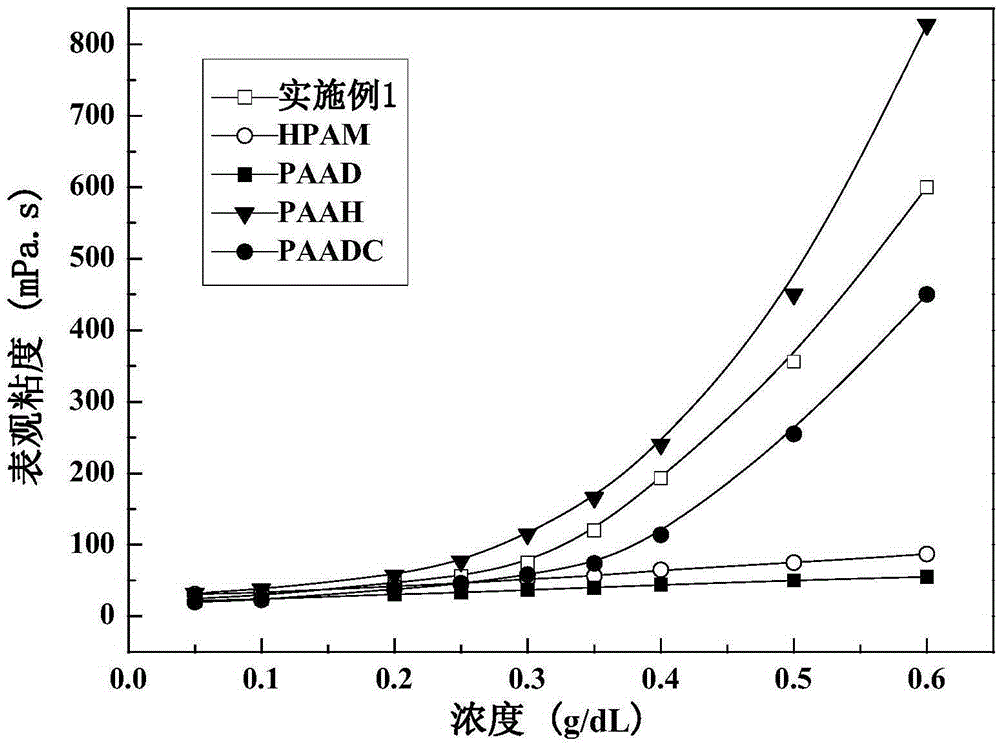

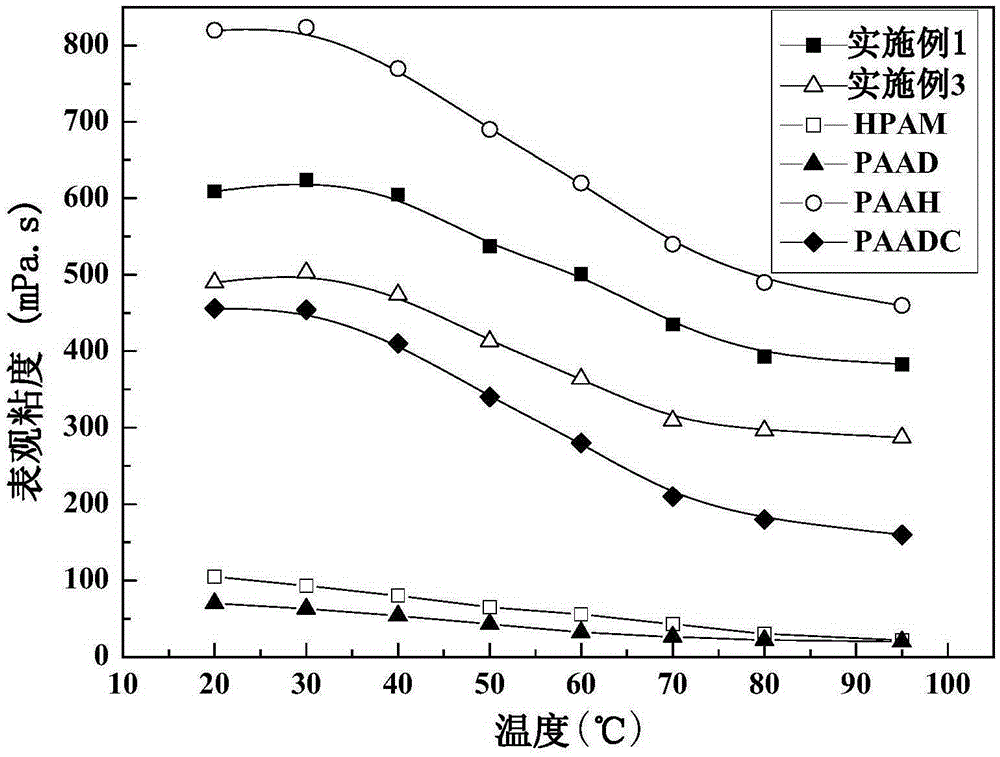

[0041] Preparation Example 1: Synthesis of Hydrophobically Associating Zwitterionic Polymers

[0042] Add 5.68g of acrylamide (0.08mol), 0.57g of acrylic acid (0.008mol) and 1.76g of methacryloxyethyltrimethylammonium chloride (0.008mol) into the reactor successively, dissolve in 40ml of distilled water, drop slowly Add 10% NaOH solution to adjust the pH of the system to 7, add distilled water to control the total monomer concentration of 15% (mass fraction), then add 2.15g of surfactant sodium dodecyl sulfate (SDS), stir well Then add 1.48g N-(5-methyl-3-tert-butyl-2-hydroxy-benzyl)acrylamide (0.006mol) and stir continuously to make it fully dissolve in the SDS micelles to form a nearly transparent homogeneous phase system. After purging nitrogen for 20 minutes to remove oxygen, add 0.047g of azobisisobutylamidine hydrochloride (0.50% of the total monomer mass), and react at a constant temperature of 56°C for 8 hours to obtain a colorless and transparent gel-like crude produ...

preparation Embodiment 2

[0043] Preparation Example 2: Synthesis of Hydrophobically Associating Zwitterionic Polymers

[0044] Add 5.68g of acrylamide (0.08mol), 0.29g of acrylic acid (0.004mol) and 0.88g of methacryloyloxyethyltrimethylammonium chloride (0.004mol) into the reactor successively, dissolve in 40ml of distilled water, drop slowly Adding a mass fraction of 10% NaOH solution to adjust the pH of the system is 7, adding distilled water to control the total monomer concentration is 15% (mass fraction), then adding 1.87g of surfactant sodium dodecyl sulfate (SDS), fully stirring Then add 1.42g N-(4-hydroxy-2-methyl-5-methylthio-benzyl)acrylamide (0.006mol) and stir continuously to fully dissolve it in the SDS micelles to form a nearly transparent homogeneous phase system. After purging nitrogen for 20 minutes to remove oxygen, add 0.041 g of azobisisobutylamidine hydrochloride (0.50% of the total monomer mass), and react at a constant temperature of 56 ° C for 8 hours to obtain a colorless an...

preparation Embodiment 3

[0045] Preparation Example 3: Synthesis of Hydrophobically Associating Zwitterionic Polymers

[0046] Add 5.68g of acrylamide (0.08mol), 0.57g of acrylic acid (0.008mol) and 1.76g of methacryloxyethyltrimethylammonium chloride (0.008mol) into the reactor successively, dissolve in 40ml of distilled water, drop slowly Adding a mass fraction of 10% NaOH solution to adjust the pH of the system to 7, adding distilled water to control the total monomer concentration of 15% (mass fraction), then adding 1.99g of surfactant sodium dodecyl sulfate (SDS), fully stirred Then add 0.77g N-(4-hydroxy-3-bromo-benzyl)acrylamide (0.003mol) and continue stirring to fully dissolve it in the SDS micelles to form a nearly transparent homogeneous system. After purging nitrogen for 20 minutes to remove oxygen, add 0.044 g of azobisisobutylamidine hydrochloride (0.50% of the total monomer mass), and react at a constant temperature of 56 ° C for 8 hours to obtain a colorless and transparent gel-like cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com