Aqueous slice multi-color paint

A multi-color paint and rock flake technology, applied in multi-color effect coatings, coatings and other directions, can solve the problems of inconvenient construction, complex production process, short storage time, etc., and achieve the effects of convenient construction, improved gloss, and convenient production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

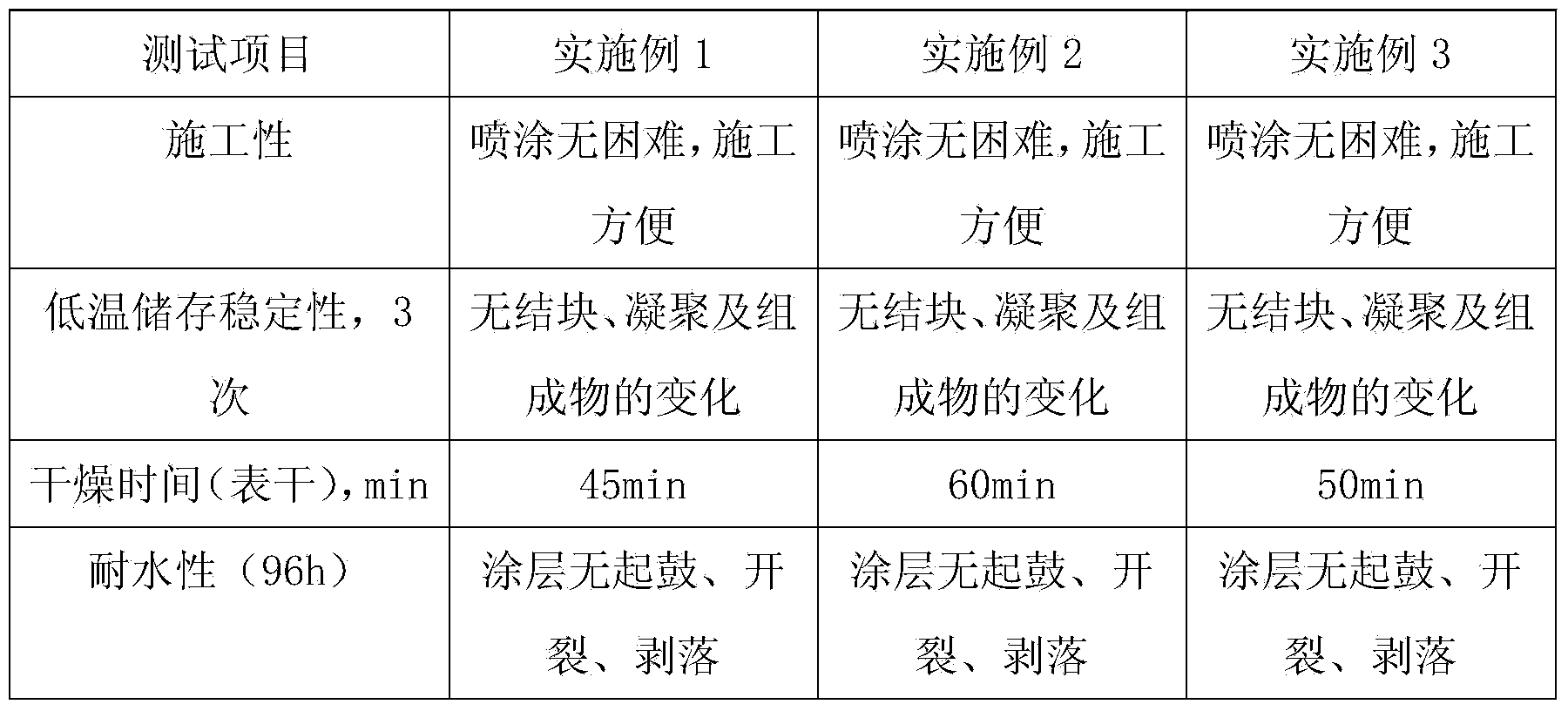

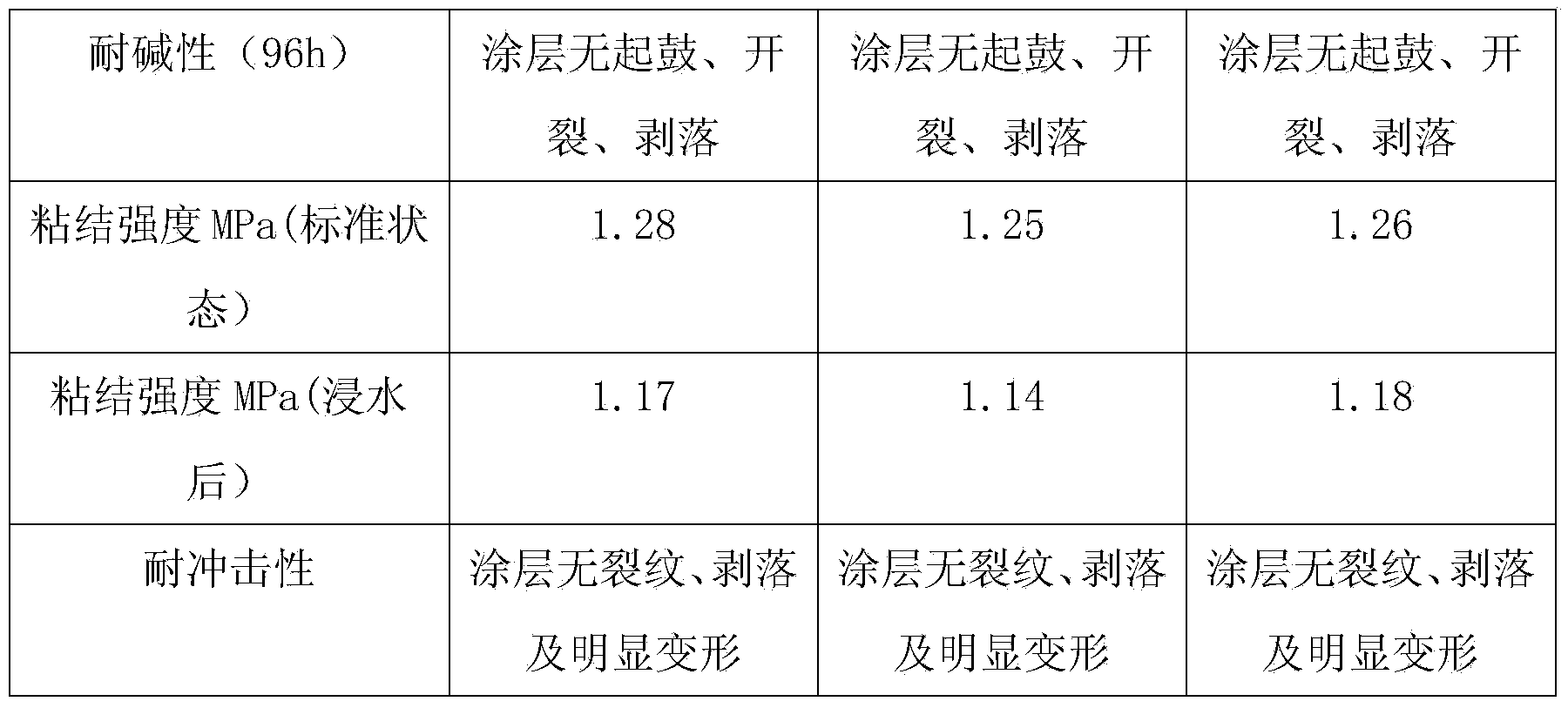

Examples

Embodiment 1

[0016] The water-based rock flake colorful paint is made of the following raw materials in parts by weight: silicone acrylic emulsion 30, wetting agent 0.03, preservative 1, defoamer 0.02, neopentyl glycol 1, carboxymethyl cellulose 0.03, pH regulator 0.03-0.05, propylene glycol 1, film-forming aid 1.2, thickener 0.3, polyamide wax 1.5, colorful rock flakes 15, woody oil 2, phytate 1, composite nano powder 5.

[0017] The preparation method of the composite nanopowder is as follows: (1) Weigh the illite, hexacyclite and sericite in a weight ratio of 8:6:4, mix them uniformly, calcinate at 860°C for 1.5h, cool to room temperature, pulverize into nanopowders, and (2) add water to the powder after sieving to make a suspension with a concentration of 45%, then add sodium polystyrene sulfonate equivalent to 6% of the suspension weight, 4% triethanolamine, 2% citric acid, 2.5% sodium tripolyphosphate and 4% polydiallyl dimethyl ammonium chloride, 4000rpm high-speed grinding for 0.5h...

Embodiment 2

[0019] The water-based rock flake colorful paint is made of the following raw materials in parts by weight: silicone acrylic emulsion 35, wetting agent 0.04, preservative 2, defoamer 0.03, neopentyl glycol 1.5, carboxymethyl cellulose 0.04, pH regulator 0.04, propylene glycol 1.5, film-forming aid 1.8, thickener 0.5, polyamide wax 2, colorful rock flakes 16, woody oil 2.5, phytate 1.5, composite nano powder 8.

[0020] The preparation method of the composite nanopowder is the same as in Example 1.

Embodiment 3

[0022] The water-based rock flake colorful paint is made of the following raw materials in parts by weight: silicone acrylic emulsion 40, wetting agent 0.05, preservative 3, defoamer 0.04, neopentyl glycol 2, carboxymethyl cellulose 0.05, pH regulator 0.05, propylene glycol 2, film-forming aid 2, thickener 0.8, polyamide wax 2.5, colorful rock flakes 20, woody oil 3, phytate 2, composite nano powder 10.

[0023] The preparation method of the composite nanopowder is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com