Thermal-insulating mortar proportioning and stirring equipment

A technology for thermal insulation mortar and production equipment, applied in mixing plants, clay preparation devices, mixing operation control, etc., can solve the problems of easily broken light materials, segregation of powder and light materials, etc., and achieve the effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

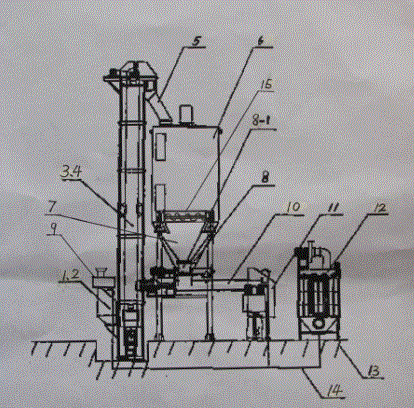

[0014] refer to figure 1 , propose an embodiment of the present invention, the present invention comprises two feeding hoppers 1.2, two elevators 3.4, upper feed bin 6, lower feed bin 7, two metering mixers, one packaging machine 11, it is characterized in that, described The two feeding hoppers 1.2, the two elevators 3.4 and the packaging machine 11 are all fixed on the foundation, the upper and lower feeding bins and the two metering mixers are supported and fixed on the foundation by metal pillars, and the two feeding hoppers 1.2 are respectively installed on the two At the feed inlet at the bottom of the elevator, the front of the hopper is connected to the first metering mixer 9, and the two elevators 3.4 are connected to the cylindrical upper hopper through a slide pipe, and the upper hopper 6 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com