High discharge device for loose unpacked material

A technology for bulk materials and unloading devices, applied in the directions of loading/unloading, packaging, transportation and packaging, can solve the problems of restricting the development of dry-mixed mortar in bulk and the segregation of dry mortar, so as to reduce and control material segregation, prevent material Segregation, solving the effect of material segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

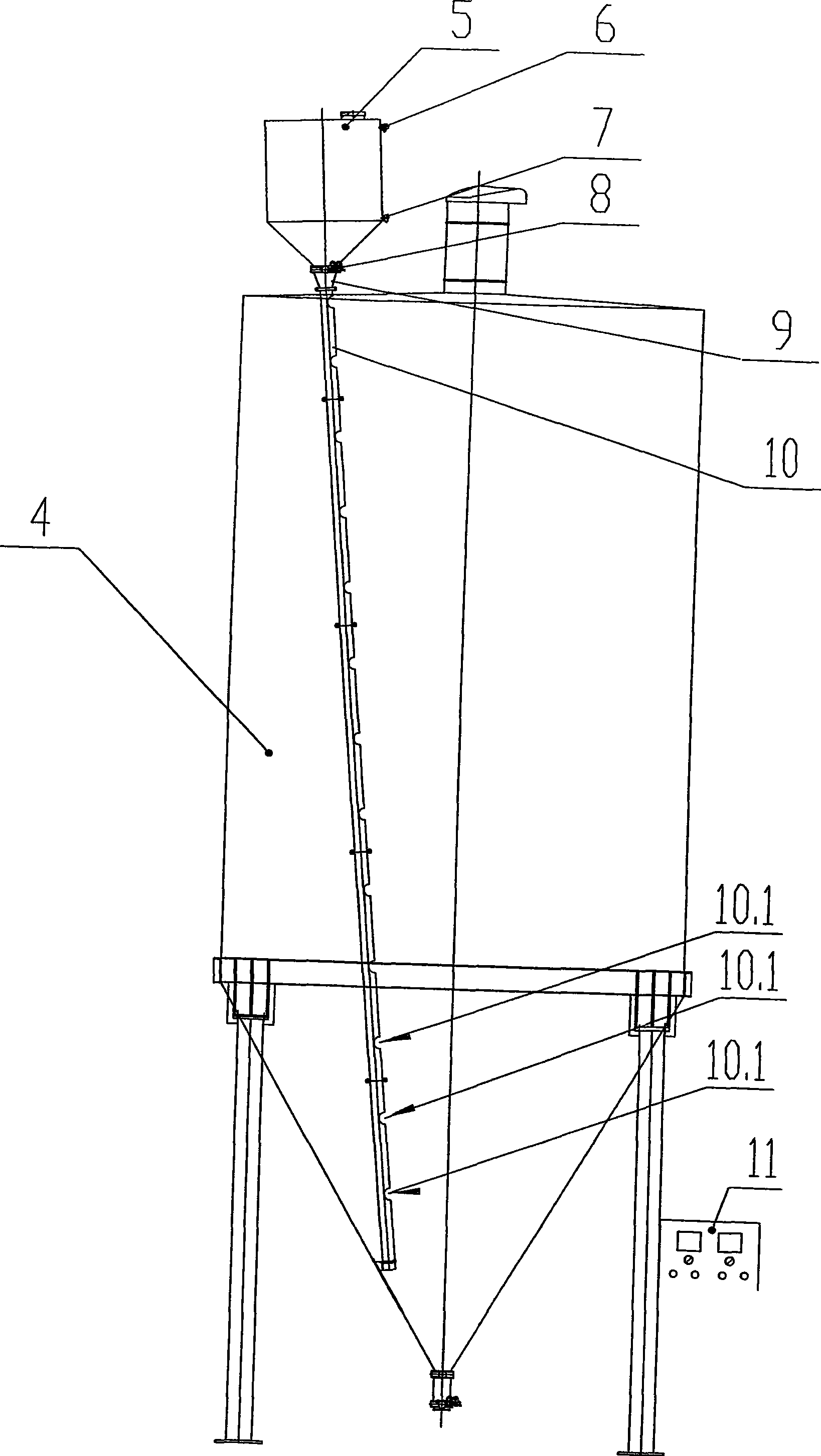

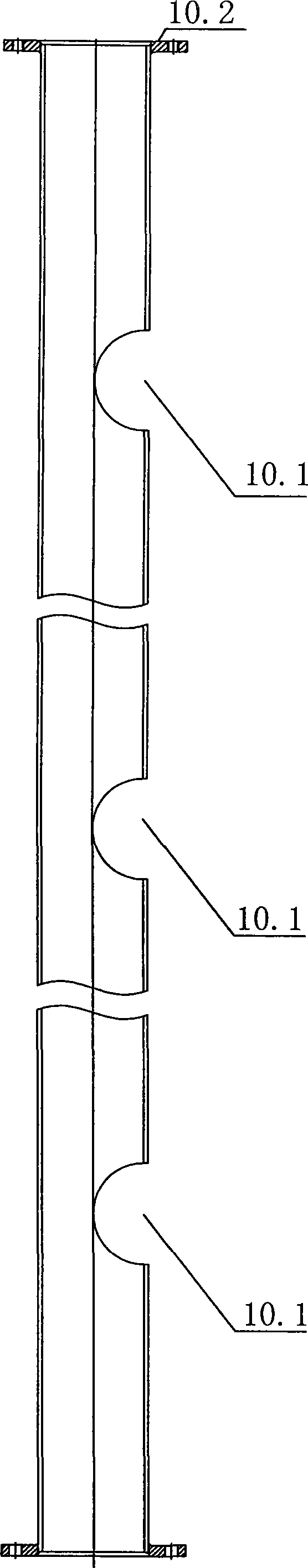

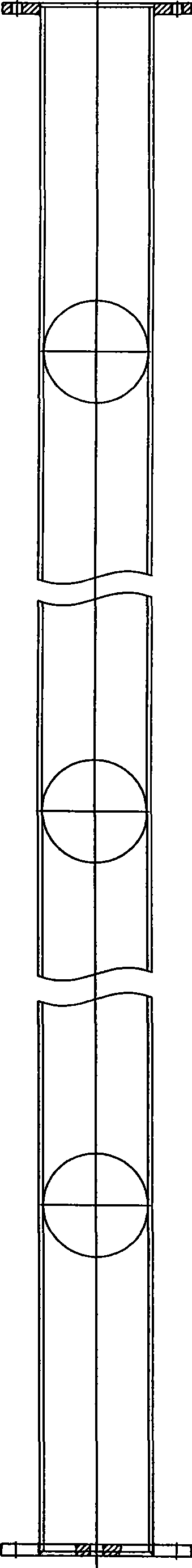

[0017] see figure 1 , The high-level unloading device for bulk materials involved in the present invention is mainly composed of a transition bin 5, a tapered transition hopper 9, a bulk bin 4, a discharge pipe 10 and an automatic control device 11. An upper material level detector 6 and a lower material level detector 7 are arranged in parallel up and down in the transition silo 5, and the upper material level detector 6 and the lower material level detector 7 are connected to the automatic control device 11. The transition silo 5 The bottom device has a conical transition hopper 9 and a discharge control gate 8. The bulk bin 4 is arranged below the conical transition hopper 9, and the discharge pipe 10 is arranged in the bulk bin 4. The upper end of the discharge pipe 10 is connected to the The outlets of the conical transition hoppers 9 are connected, and the lower end is arranged in the bulk bin 4 . Several discharge holes 10.1 are opened transversely on the discharge pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com