High-viscosity asphalt additive modifier and preparation method thereof and high-viscosity modified asphalt and preparation method thereof

A modifier and high-viscosity technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of large porosity of permeable asphalt pavement and reduced durability of pavement, and achieve easy packaging, easy mixing, and avoiding segregation problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In the high-speed mixer, first add 100 parts by weight of SBS, 15 parts by weight of C9 petroleum resin, 20 parts by weight of EVA, 70 parts by weight of white mineral oil, 3 parts by weight of epoxy soybean oil, and 15 parts by weight of furfural extracted oil, and mix well; Then add 7 parts by weight of PP wax, 1 part by weight of zinc stearate, 0.5 parts by weight of antioxidant 1010, and 70 parts by weight of calcium carbonate powder and mix uniformly; Cut into pellets to obtain high-viscosity asphalt externally mixed with modifier D1.

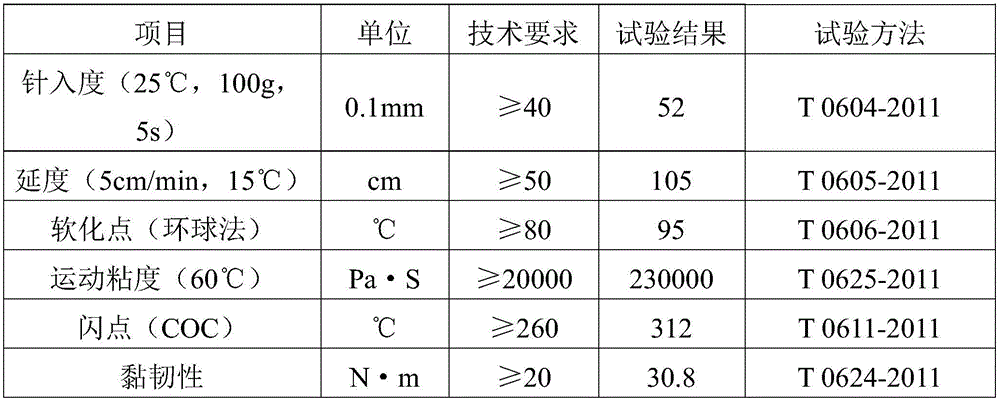

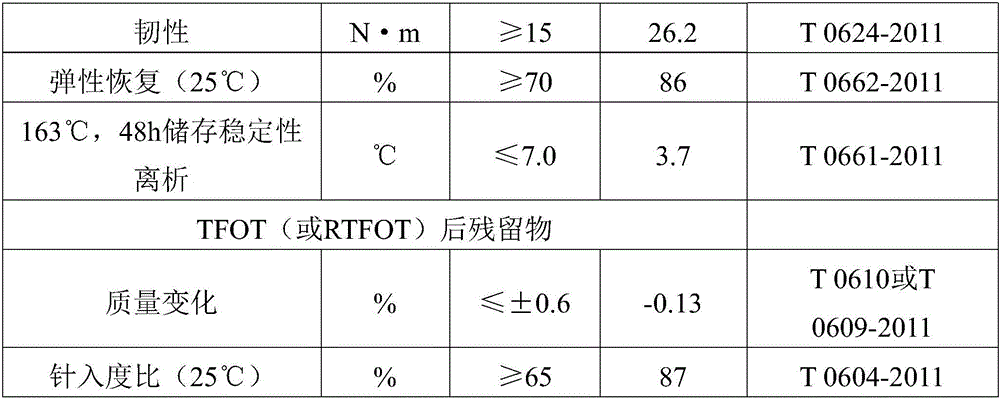

[0032] Prepare high-viscosity modified asphalt with the above-mentioned high-viscosity asphalt externally mixed modifier, and its parts by weight are composed of 10 parts by weight of high-viscosity asphalt externally mixed with modifier D1, 90 parts by weight of 70# petroleum asphalt, and the high-viscosity asphalt is externally mixed to modify Add the additive D1 to the hot 70# petroleum asphalt and stir it at high speed for 1.5h ...

Embodiment 2

[0034] First add 100 parts by weight of SBS, 15 parts by weight of C9 petroleum resin, and 20 parts by weight of EVA into the high-speed mixer, and mix well; then add 1 part by weight of zinc stearate, and mix well; Pelletizing, pelletizing by a pelletizer to obtain high-viscosity asphalt mixed with modifier D2.

[0035] Prepare high-viscosity modified asphalt with the above-mentioned high-viscosity asphalt externally mixed modifier, and its parts by weight are composed of 10 parts of high-viscosity asphalt externally mixed with modifier D1, 90 parts of 70# petroleum asphalt, and high-viscosity asphalt externally mixed with modifier Add it into hot 70# petroleum asphalt, and stir at high speed for 1.5 hours to obtain high-viscosity modified asphalt DS2.

Embodiment 3

[0037] In the high-speed mixer, first add 100 parts by weight of SEBS, 9 parts by weight of C9 petroleum resin, 18 parts by weight of EVA, 100 parts by weight of white mineral oil, 4 parts by weight of epoxy soybean oil, and 20 parts by weight of furfural extract oil, and mix well; Then add 10 parts by weight of PP wax, 2 parts by weight of zinc stearate, 0.4 parts by weight of antioxidant 1010, and 50 parts by weight of calcium carbonate powder and mix uniformly; Cut into pellets to obtain high-viscosity asphalt externally mixed with modifier D3.

[0038] Prepare high-viscosity modified asphalt with the above-mentioned high-viscosity asphalt externally mixed modifier, and its parts by weight are composed of 8 parts by weight of high-viscosity asphalt externally mixed with modifier D3, 92 parts by weight of 70# petroleum asphalt, and the high-viscosity asphalt is externally mixed to modify The additive was added to hot 70# petroleum asphalt, and stirred at high speed for 2 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com