Direct-adding type instant SBS (Styrene Butadiene Styrene) modifier as well as preparation method and application thereof

A modifier, instant technology, used in building components, building insulation materials, buildings, etc., can solve the softening point and ductility decline of modified asphalt, the large difference in the properties of modified asphalt, and the uneven dispersion of asphalt. problems, to achieve the effect of reducing heating time, overcoming technical defects, saving fuel, energy and processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of direct throw type instant SBS modifier comprises the raw material of following weight portion:

[0045]

[0046] The preparation method of described direct throw type instant type SBS modifier comprises the following steps:

[0047] First, grind the SBS into a powder with a particle size below 120 mesh through a plastic mill. Then, after weighing each material according to the required amount, add it to a high-speed mixer, and mix at a high speed of 500r / min for 5min, and control the mixing temperature below 50°C. The homogeneously mixed materials are fed into the extruder to undergo melt extrusion and granulation. The temperature of the extruder is divided into 7 zones from the feeding section to the die head temperature. The temperature is controlled at 120°C, 145°C, 170°C, 185°C, 190°C, 190°C, and 180°C, and the fluctuation range is ±2°C.

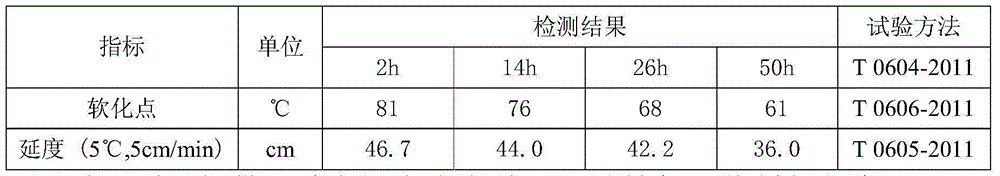

[0048] figure 1 The appearance of the direct-throwing instant SBS modifier prepared for Example 1 of the present...

Embodiment 2

[0051] Same as Example 1, except that the raw material fractions are: 75 parts of SBS; 15 parts of ethylene-vinyl acetate copolymer; 10 parts of naphthenic oil; 2 parts of compatibilizer; 3 parts of antioxidant.

Embodiment 3

[0053] Same as Example 1, except that the raw material fractions are: 75 parts of SBS; 10 parts of ethylene-vinyl acetate copolymer; 10 parts of naphthenic oil; 2 parts of compatibilizer; 3 parts of antioxidant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com