Device for composting concrete aggregate with large particle diameter

A technology of large particle size and concrete, which is applied in the direction of transportation, packaging, loading/unloading, etc. It can solve the problems of unreasonable particle size and segregation of coarse aggregate, and achieve the effect of avoiding aggregate separation, convenient use and saving purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

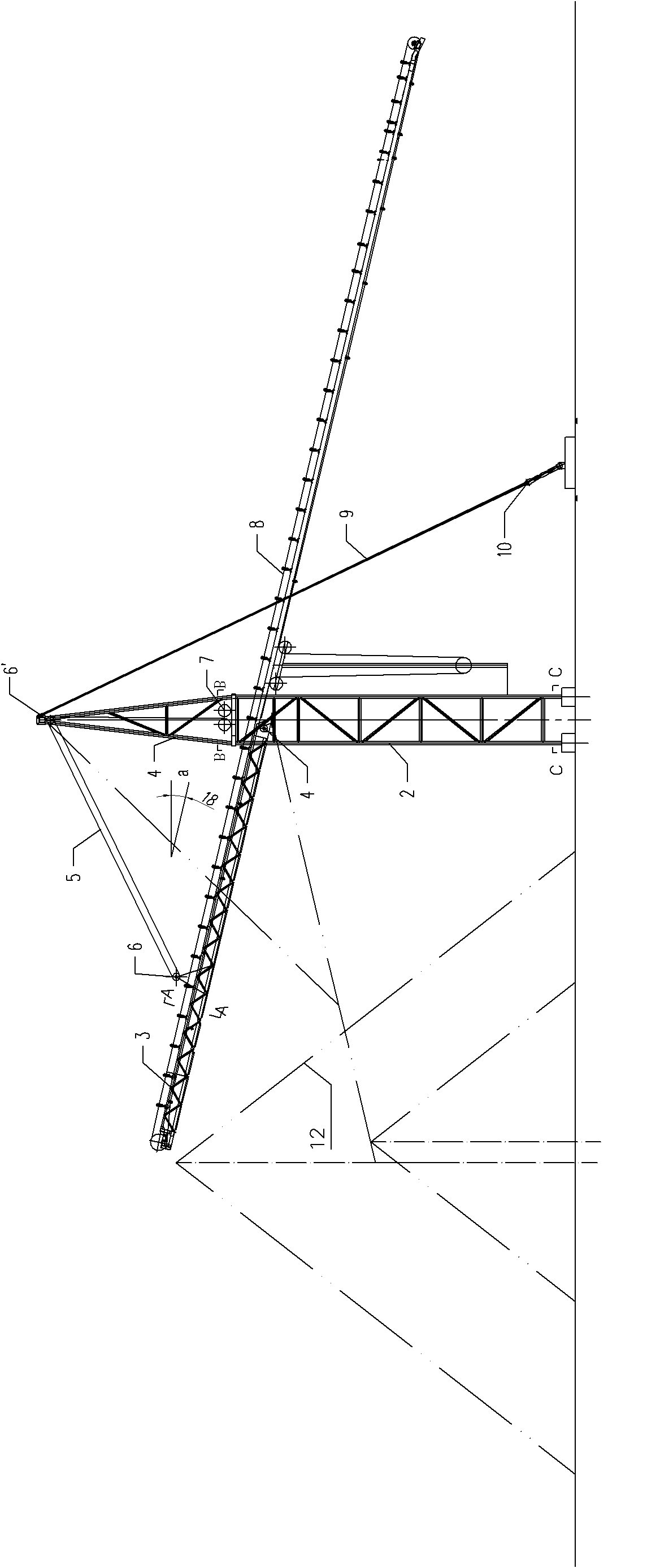

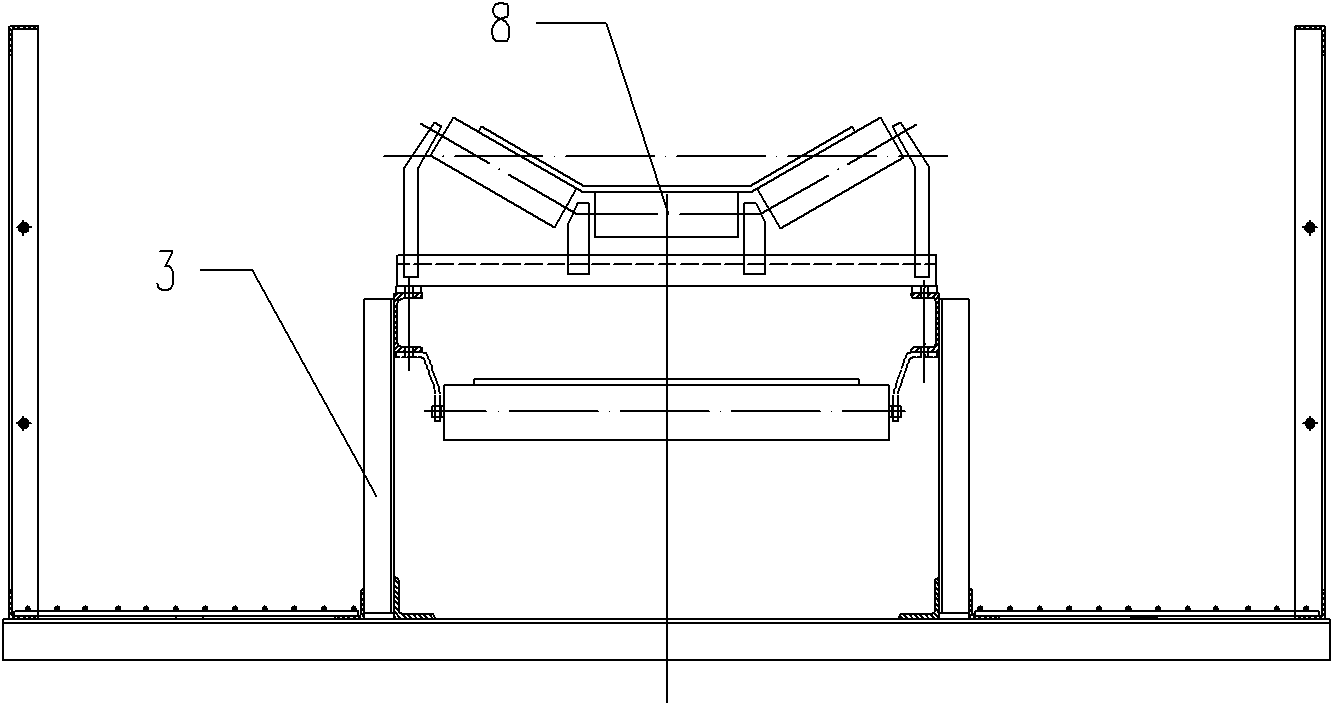

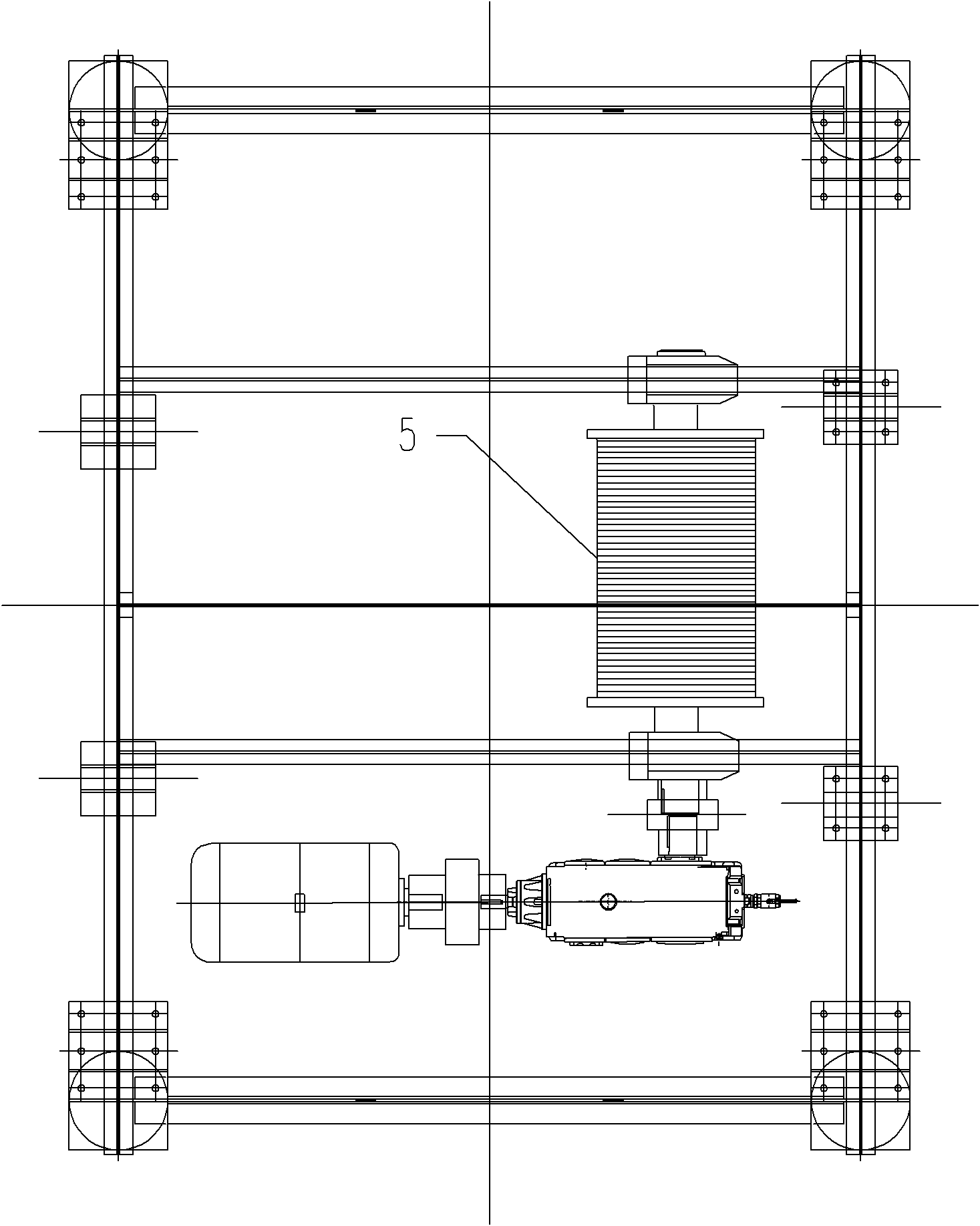

[0015] Such as figure 1 As shown, a stacking device for concrete large-size aggregates includes a tower frame 1, and the tower frame 1 is installed on a steel column 2. Two hinge supports 4, the movable cantilever truss beam 3 is connected with the hinge support 4 through pivot pins; the hoist 7 is installed on the hoist working platform 11, the tape machine 8 is installed on the movable cantilever truss beam 3, the steel wire rope 5 of the hoist 7 The two pulley blocks 6, 6' are connected with the movable suspension truss beam 3, one end of the cable 9 is fixed on the ground through the adjustment rod 10, and the other end is connected with the tower 1.

[0016] The two hinge supports 4 are arranged on the working platform 11 of the hoist along the symmetrical direction of the axis of the belt conveyor 8 .

[0017] The active cantilever truss beam is composed of three parts: the head connection section, the truss middle connection section, and the tail connection section. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com