Construction waste sorting and crushing equipment

A technology for processing equipment and construction waste, which is applied in grain processing, solid separation, chemical instruments and methods, etc., can solve the problems of increasing costs, sorting materials that cannot be sorted, and clogging, and achieve the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

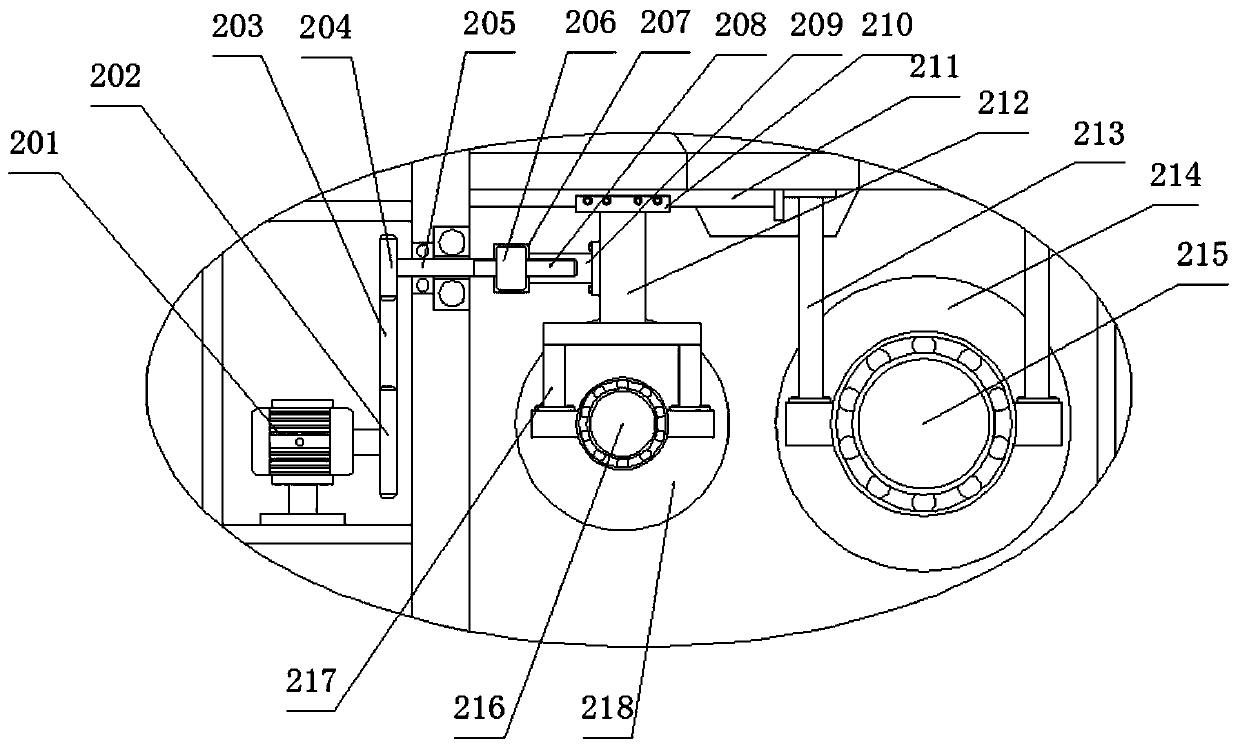

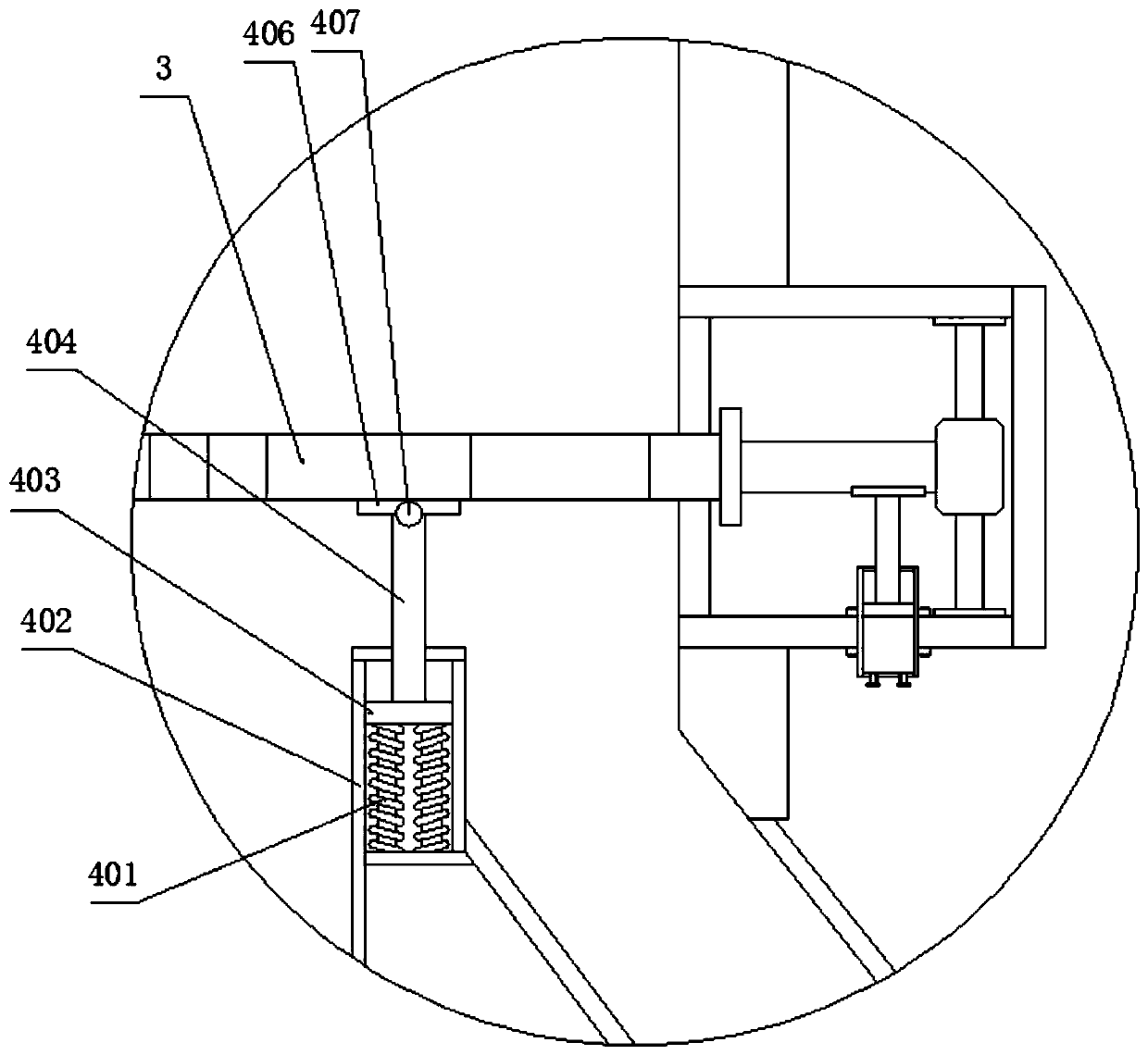

[0020] The accompanying drawings are only for illustrative purposes and cannot be understood as a limitation of the patent; in order to better illustrate this embodiment, some parts of the accompanying drawings may be omitted, enlarged or reduced, and do not represent the size of the actual product; For personnel, it is understandable that some well-known structures in the drawings and their descriptions may be omitted.

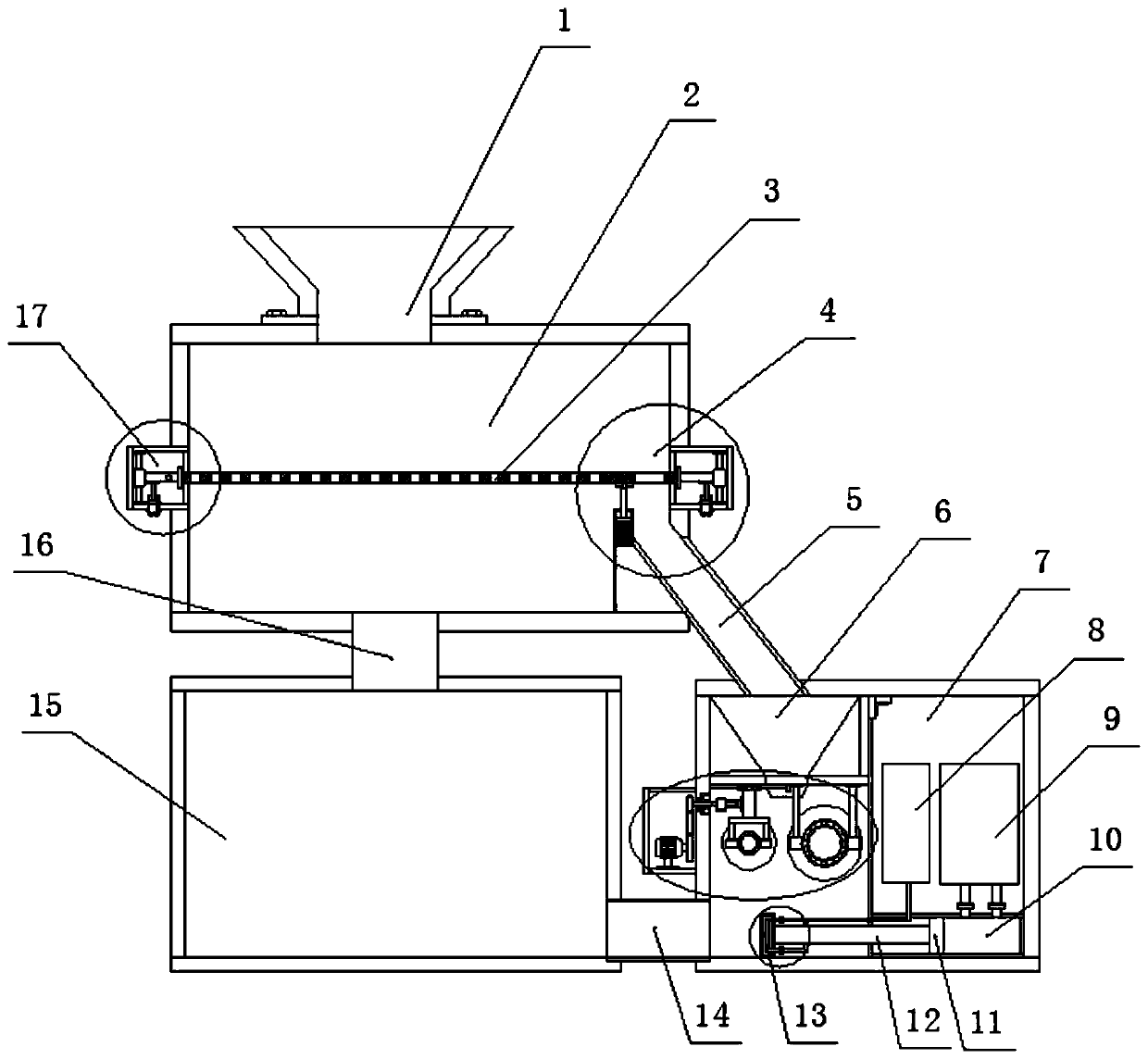

[0021] With reference to the figures, a construction waste sorting and crushing treatment equipment includes a screening box 2, a crushing box, and a collection box 15. The screening box 2 and the crushing box are connected through five crushing pipes, and the screening box 2 and the collection box 15 pass through the discharge pipe 16 is connected, the collection box 15 and the crushing box are connected by a connecting pipe 14. The top of the screening box 2 is connected with a filling port 1, and the inside of the screening box 2 is provided with a sieve plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com