Hot-mix cold-lay rubber asphalt mixture

A technology for rubberized asphalt and mixtures, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., to achieve the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

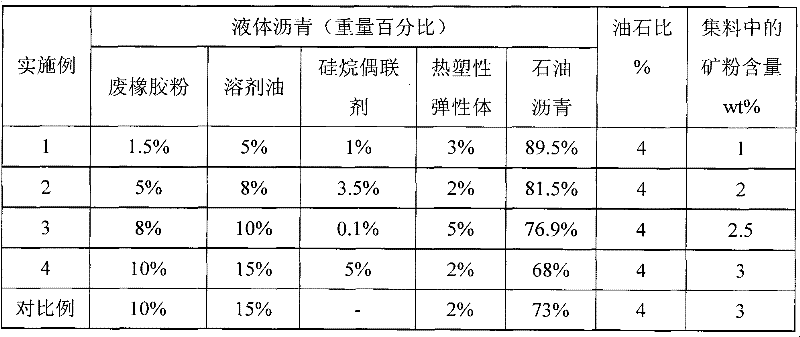

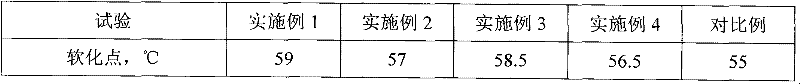

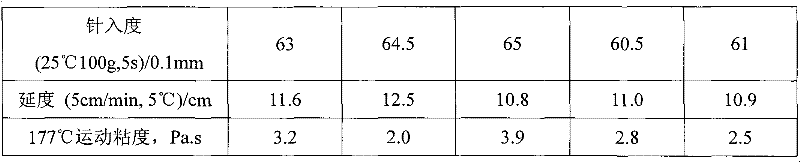

[0018] The present invention is further set forth below in conjunction with embodiment. It should be understood that these examples are only used to illustrate the present invention, not to limit the scope of the present invention.

[0019] 1. Material selection

[0020] Waste rubber powder: It is made by crushing waste tires, 40-80 mesh.

[0021] Solvent oil: rubber solvent oil, the boiling range is 80-120°C.

[0022] Silane coupling agent: the model is KH550.

[0023] Thermoplastic elastomer: BT-1047D.

[0024] Petroleum asphalt: 70#-A grade road petroleum asphalt, ductility 164cm, softening point 52.5°C, flash point 295°C, penetration 79mm.

[0025] 2. Grading range: Granite is used for coarse aggregate and fine aggregate, and the grading range is shown in Table 1.

[0026] Table 1 Grading of aggregates

[0027] Mesh size / mm

9.5

4.75

2.36

1.18

0.6

0.3

0.15

0.075

Passing percentage / %

100

86

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com