Optical glass for precise compression molding

A molding and optical glass technology, applied in the field of optical glass, can solve the problems of lowering glass transition temperature, increasing glass cost, and high glass cost, and achieves the effects of good melting, excellent devitrification resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

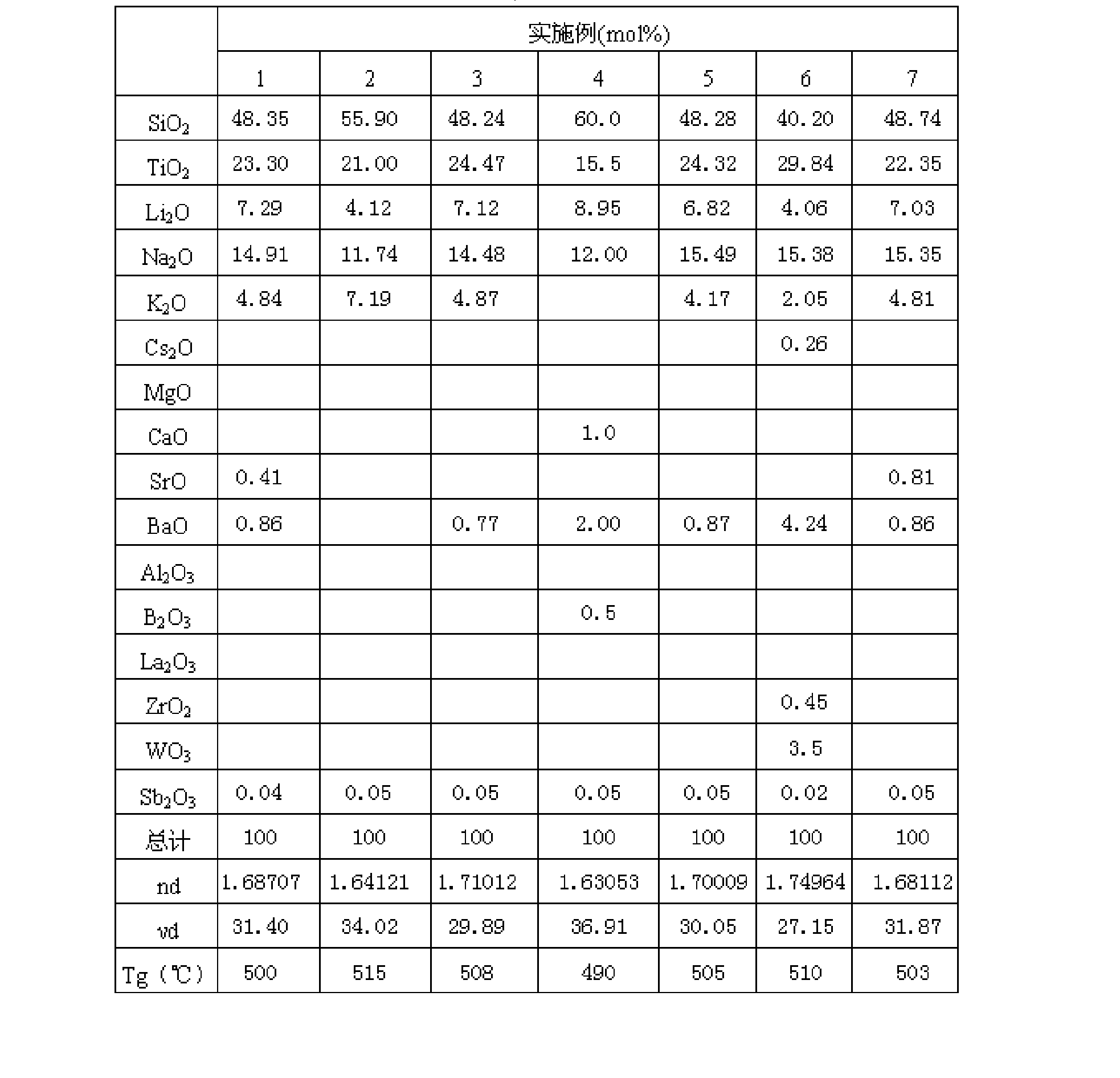

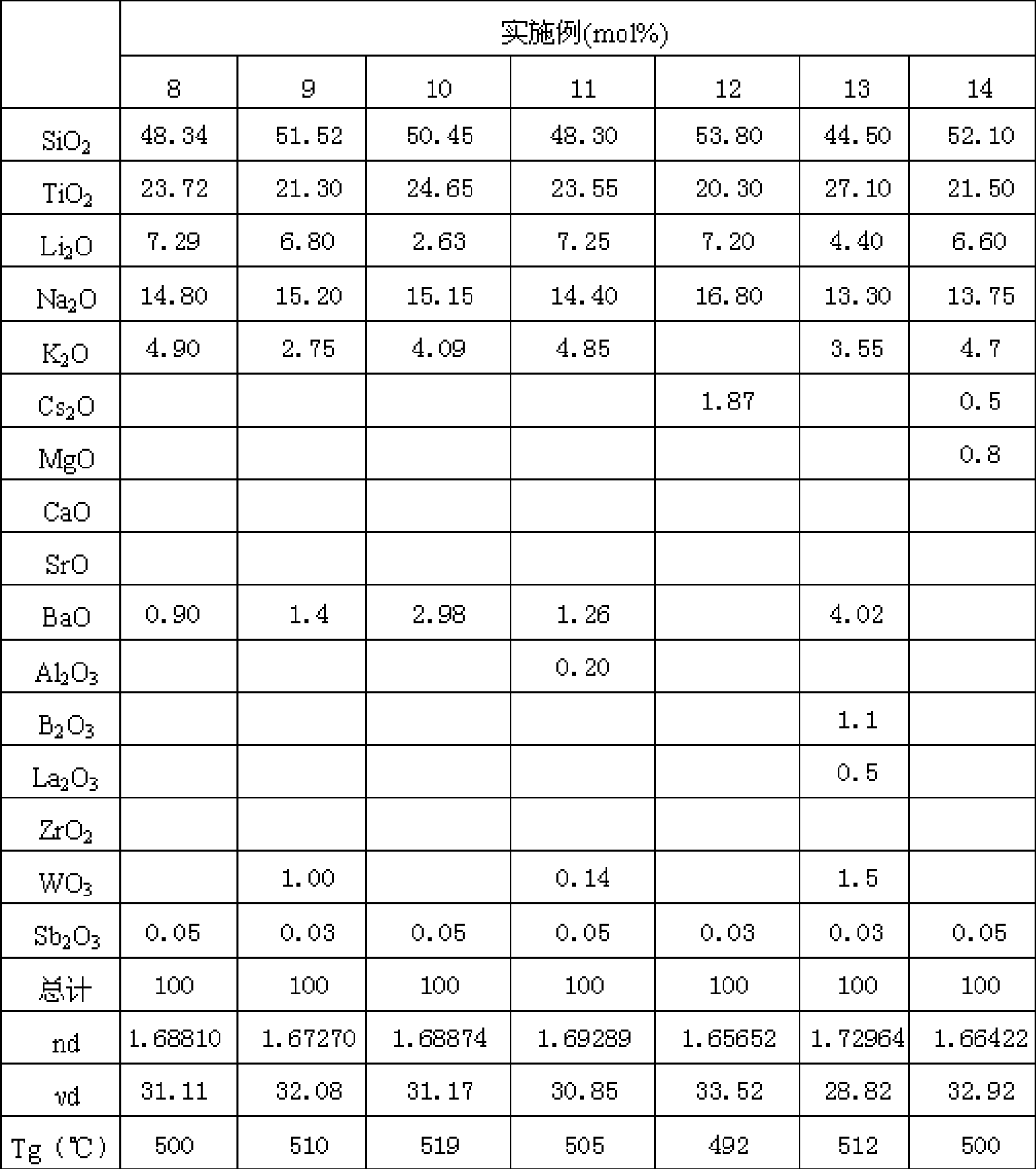

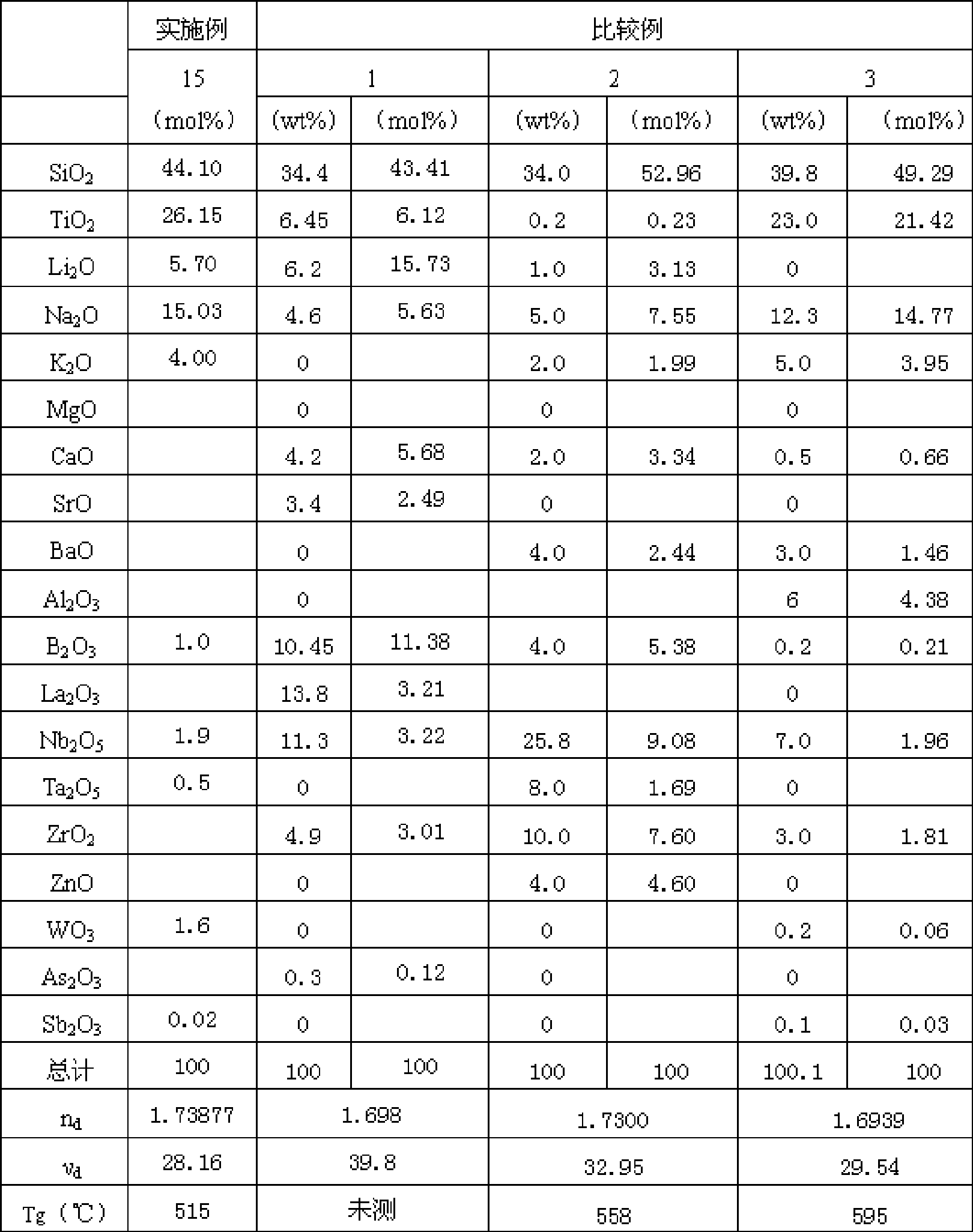

Examples

Embodiment Construction

[0019] The inventors determined the molar percentage (mol%) ranges of the above components on the basis of a large number of experiments.

[0020] The reasons for limiting the composition range of each component as mentioned above in the optical glass of the present invention are specifically described below, and the amount of each component is represented by the amount of the substance:

[0021] SiO 2 It is an essential component of the optical glass of the present invention, SiO 2 The component is an oxide that forms glass, and at the same time, when the present invention contains a large amount of alkali metal oxide component, it is also an effective component for adjusting the viscosity of the glass, improving the chemical stability of the glass, and inhibiting the tendency of glass devitrification. When the amount is less than 40%, the above-mentioned effects are not sufficient; and when it exceeds 60%, the melting property of the glass becomes poor, and unmelted objects...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com