Optical glass

A technology of optical glass and optical components, applied in optics, optical components, instruments, etc., can solve the problems of reducing glass cost, disadvantages, and reducing glass devitrification resistance, achieving excellent devitrification resistance and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0084]

[0085] In order to further clearly illustrate and illustrate the technical solution of the present invention, the following non-limiting examples are provided.

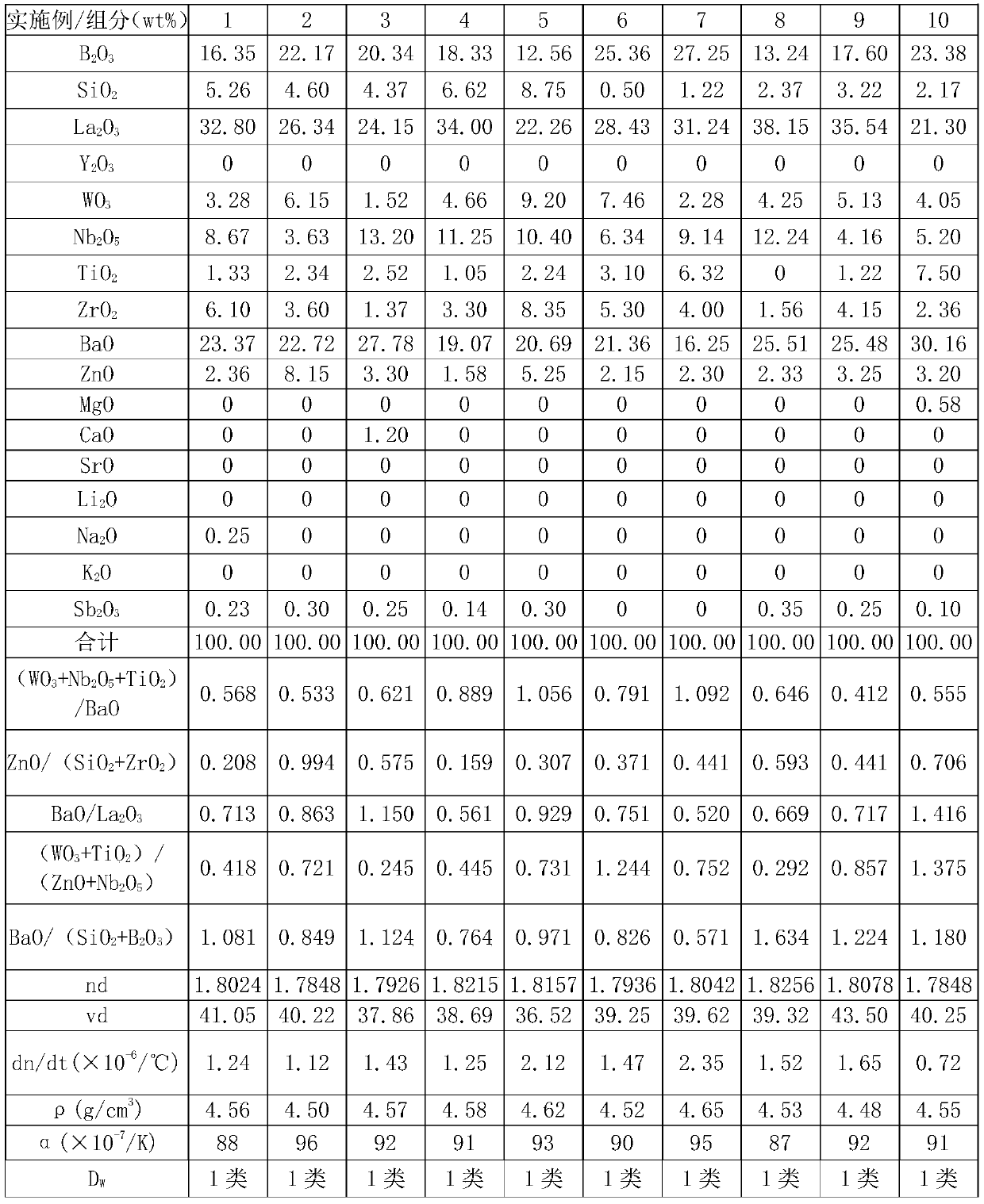

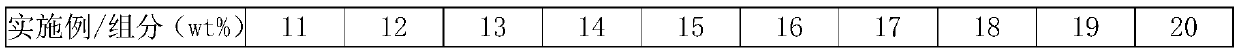

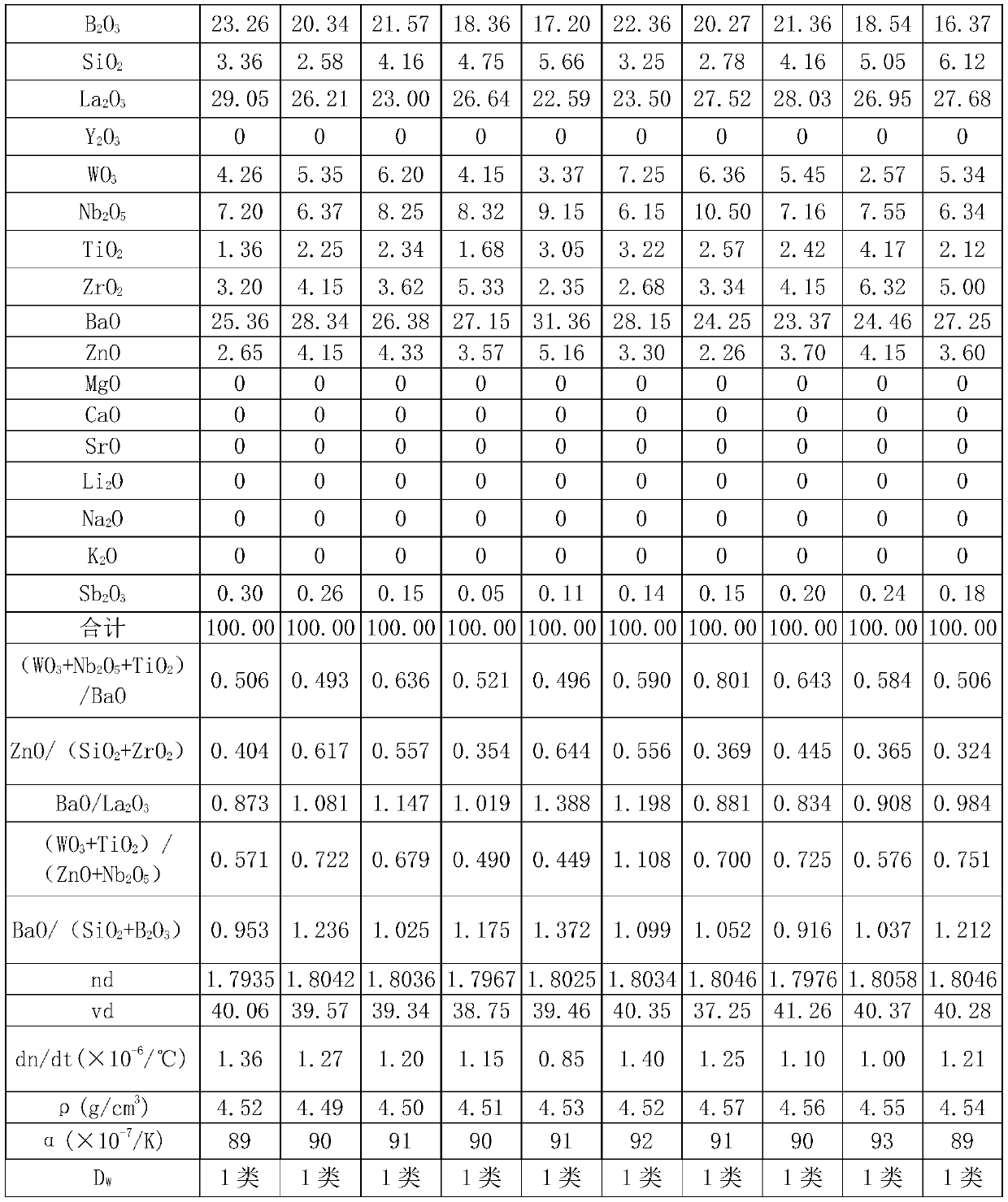

[0086] In this example, the optical glass having the compositions shown in Table 1 to Table 3 was obtained by using the above-mentioned manufacturing method of optical glass. In addition, the properties of each glass were measured by the test method described in the present invention, and the measurement results are shown in Tables 1 to 2.

[0087] Table 1.

[0088]

[0089] Table 2.

[0090]

[0091]

[0092]

[0093] The glasses obtained in Examples 1 to 20 of the optical glass are used, for example, by means of grinding, or hot press molding, precision stamping, and other compression molding methods to produce concave meniscus lenses, convex meniscus lenses, and double-convex lenses. , biconcave lens, plano-convex lens, plano-concave lens and other prefabricated parts of various lenses and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com