Optical glass, preform for precision press molding and optical element using the same

A technology of optical glass and preforms, applied in optical components, optics, instruments, etc., can solve problems such as high refractive index, low-pressure molding temperature, and difficulty, and achieve high refractive index and prevent deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

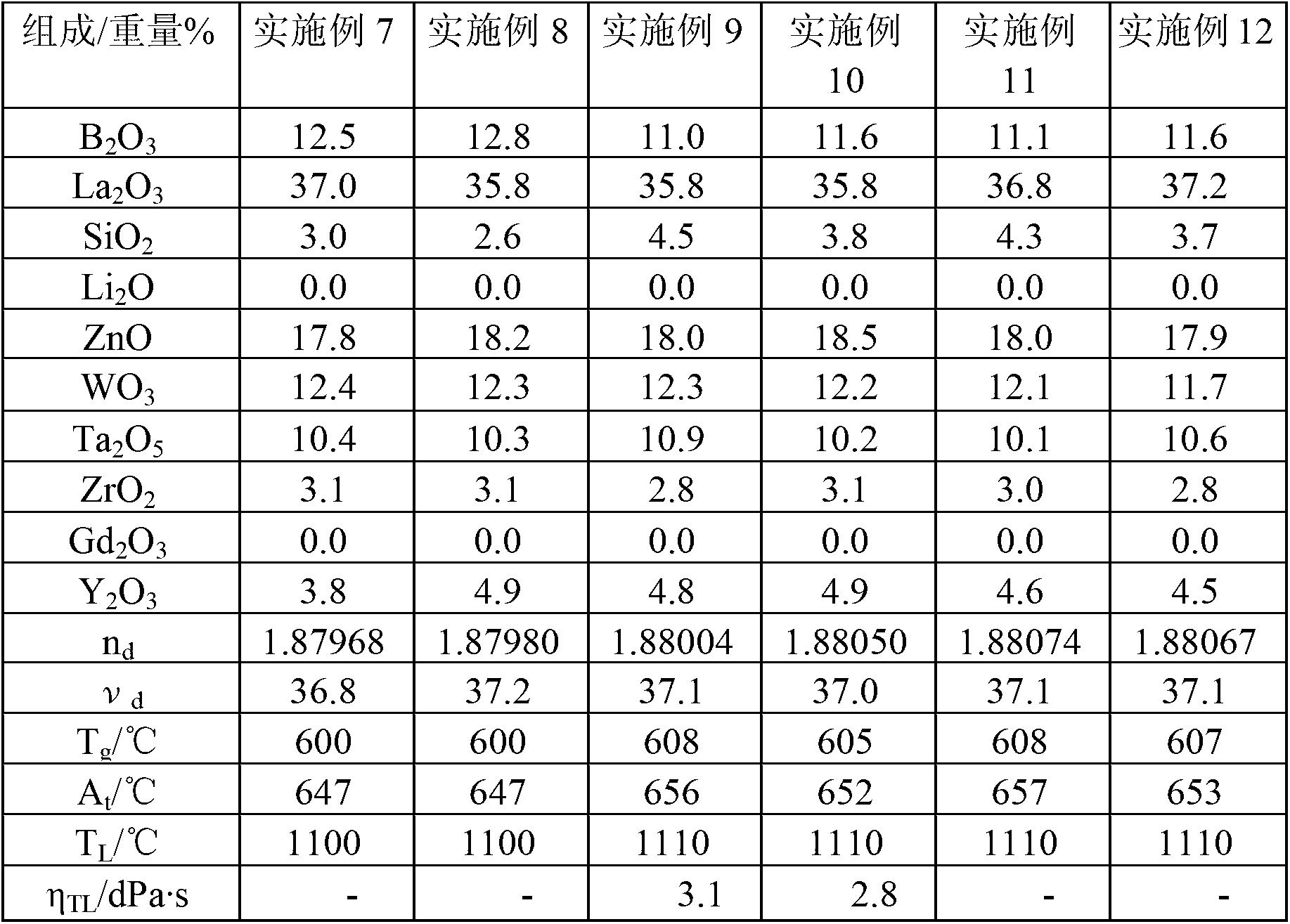

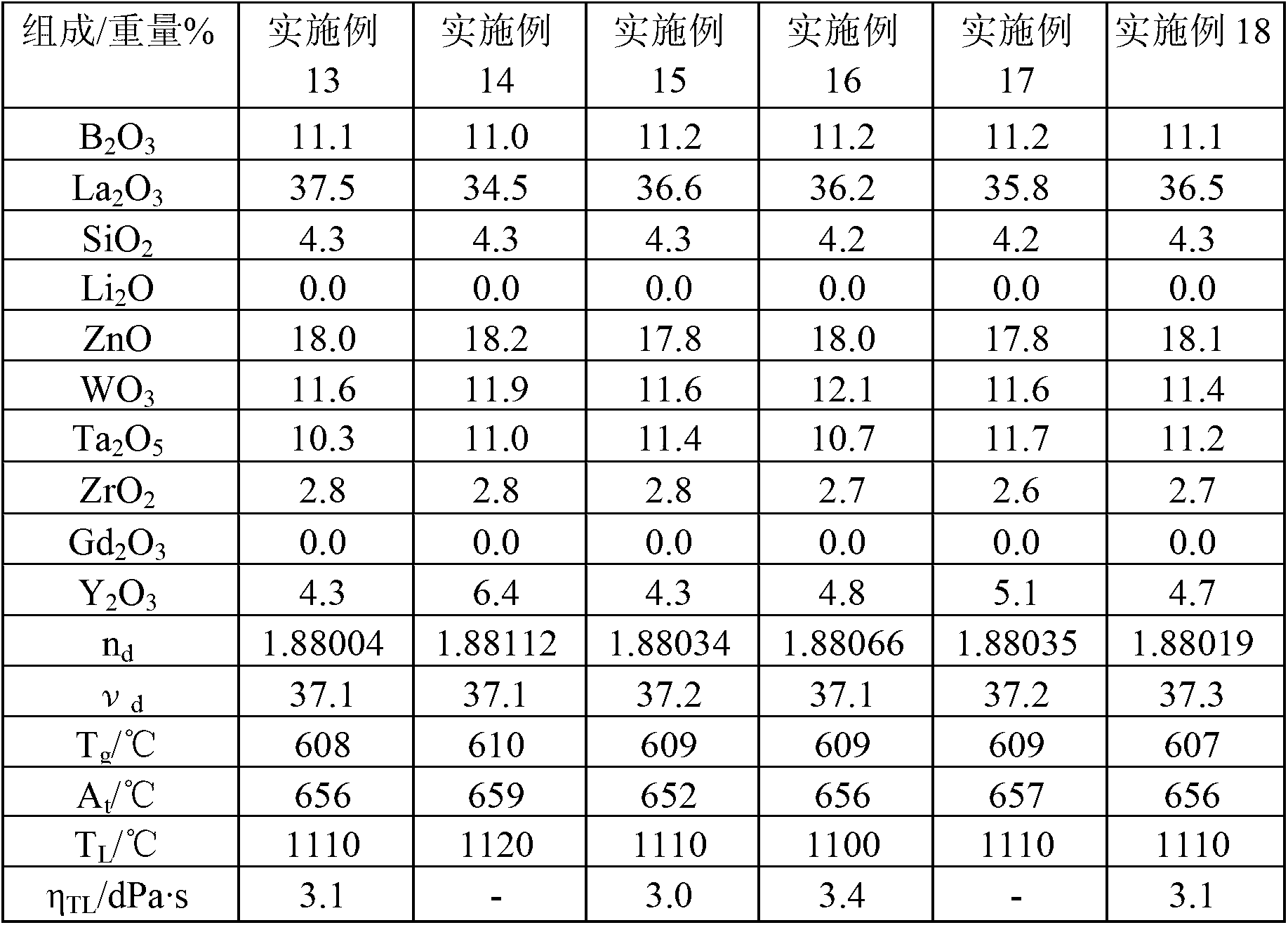

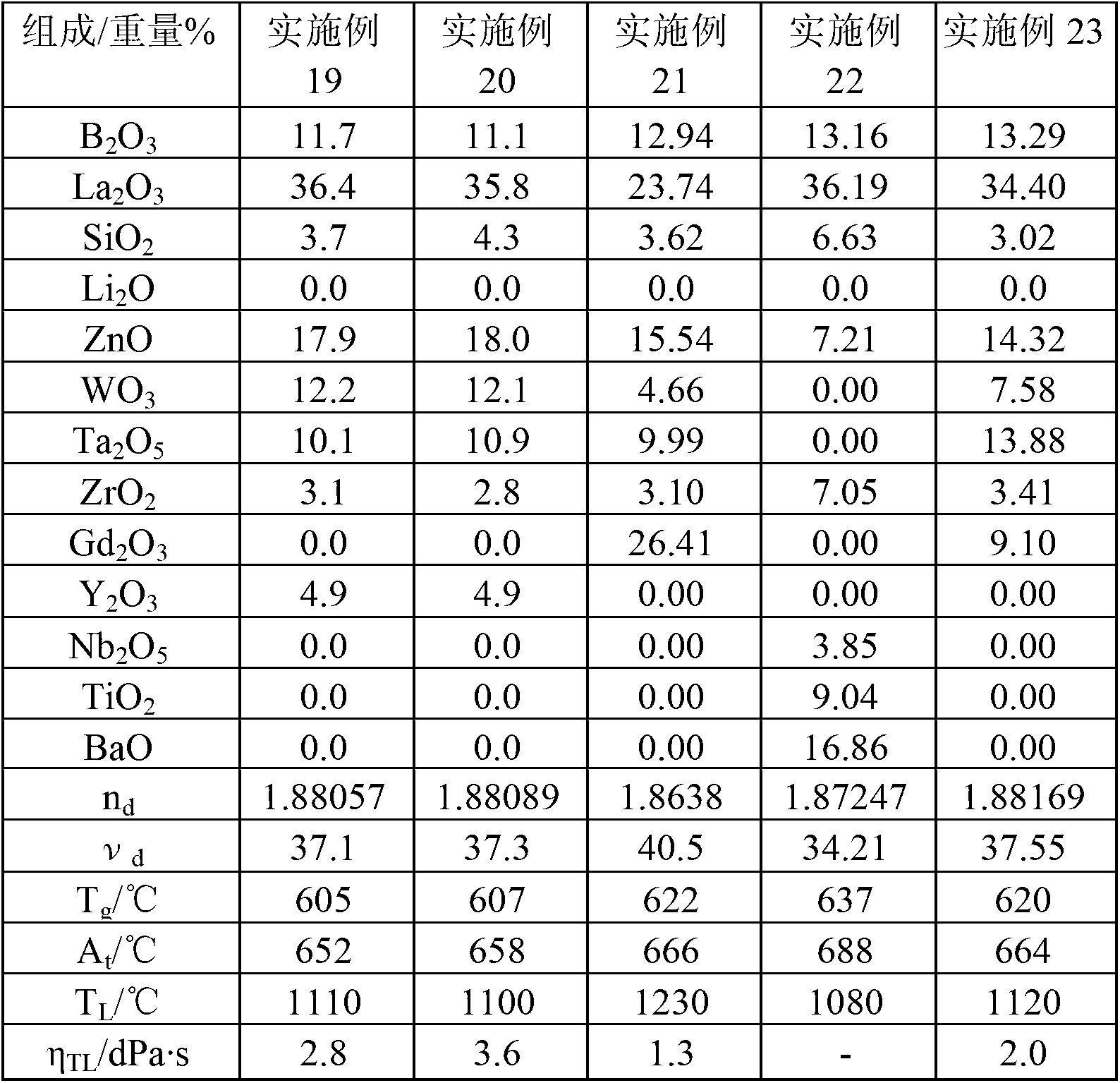

[0065]Specific embodiments of the present invention will be described below, but the present invention is not limited thereto. Here, Examples 1 to 20 are inventive examples of the present invention, and Examples 21 to 23 are comparative examples. Example 21 shows the glass composition described in Example 44 of Patent Document 1 cited in Background Art. Similarly, Example 22 shows Example 3 in Patent Document 2, and Example 23 shows Example 30 in Patent Document 3. Physical properties not described in the specification of each patent document were measured for the glass prepared by the method described in the example of the specification of each patent document by the method to be mentioned below. Incidentally, the values of the respective components expressed in mol % based on oxides are shown in Tables 5 to 8. In addition, the La 2 o 3 and Y 2 o 3 The total content of is abbreviated as La+Y in the table, and "-" indicates that there is no measured value. However, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| liquidus temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com