Synthetic fiber fabric and quick dimension stabilization method thereof

A technology of synthetic fiber and stabilization method, which is applied in the field of synthetic fiber fabric and its rapid size stabilization, and can solve the problems of severe shrinkage, unsuitable synthetic fiber, poor thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

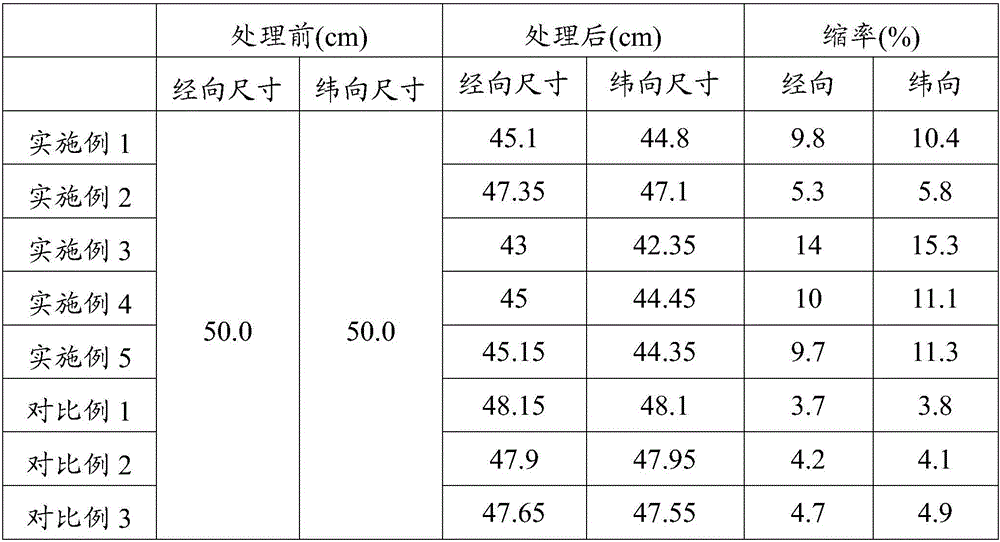

Examples

Embodiment 1

[0029] In this embodiment, a method for rapidly stabilizing the size of synthetic fiber fabrics, the synthetic fiber fabrics used are plain weave, the warp and weft yarns are 600D polypropylene filaments, the warp density is 21 threads / inch, and the weft density is 37 threads / inch. For gray fabrics that have not been sorted, the method for rapid size stabilization includes the following steps:

[0030] (1) Desizing: A continuous open-width desizing machine is used. The formula of the desizing working fluid is: sodium carbonate 2g / L, non-ionic surfactant LCF185 2g / L; at 90°C, steam the synthetic fiber fabrics in a stacking box for 60 seconds; then wash the synthetic fiber fabrics in a washing tank at 60°C, and dry them with a dryer at 100°C to complete desizing.

[0031] (2) Liquid ammonia finishing: use a continuous open-width liquid ammonia finishing machine to carry out liquid ammonia finishing on the synthetic fiber fabrics after desizing. ℃; then carry out liquid ammonia ...

Embodiment 2

[0035] In this embodiment, a method for rapidly stabilizing the size of a synthetic fiber fabric, the synthetic fiber fabric used is the same as in Example 1, and the method for rapidly stabilizing the size includes the following steps:

[0036] (1) Desizing: A continuous open-width desizing machine is used. The formula of the desizing working fluid is: sodium carbonate 1g / L, non-ionic surfactant LCF185 5g / L; at 100°C, steam the synthetic fiber fabrics in a stacking box for 40 seconds; then wash the synthetic fiber fabrics in a washing tank at 60°C, and dry them with a dryer at 100°C to complete desizing.

[0037] (2) Liquid ammonia finishing: use a continuous open-width liquid ammonia finishing machine to carry out liquid ammonia finishing on the synthetic fiber fabric after desizing, firstly carry out pre-drying by pre-drying tension roller, the pre-drying tension is 400N, and the pre-drying temperature is 100 ℃; then control the vehicle speed to 60m / min (maintain this vehic...

Embodiment 3

[0041] In this embodiment, a method for rapidly stabilizing the size of a synthetic fiber fabric, the synthetic fiber fabric used is the same as in Example 1, and the method for rapidly stabilizing the size includes the following steps:

[0042] (1) Desizing: A continuous open-width desizing machine is used. The formula of the desizing working fluid is: sodium carbonate 1g / L, non-ionic surfactant LCF185 0.5g / L; the control speed is 45m / min, and the stacking box The temperature is 70°C, and the synthetic fiber fabric is steamed in a stacking box for 80s; then the synthetic fiber fabric is washed in a washing tank at 60°C, and dried with a dryer at a temperature of 100°C, and the desizing is completed .

[0043] (2) Liquid ammonia finishing: use a continuous open-width liquid ammonia finishing machine to carry out liquid ammonia finishing on the synthetic fiber fabrics after desizing. ℃; then control the vehicle speed to 10m / min (maintain this vehicle speed in subsequent steps)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com