Method for improving physical properties of polyimide film and polyimide film production line

A technology of polyimide film and physical properties, which is applied in the polyimide film production line to improve the physical properties of polyimide film, can solve the problems of doubling the investment cost, increasing the number of synthesis devices, and cumbersome viscosity adjustment. Achieve the effects of simple structure, improved thickness uniformity, and improved film roll flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

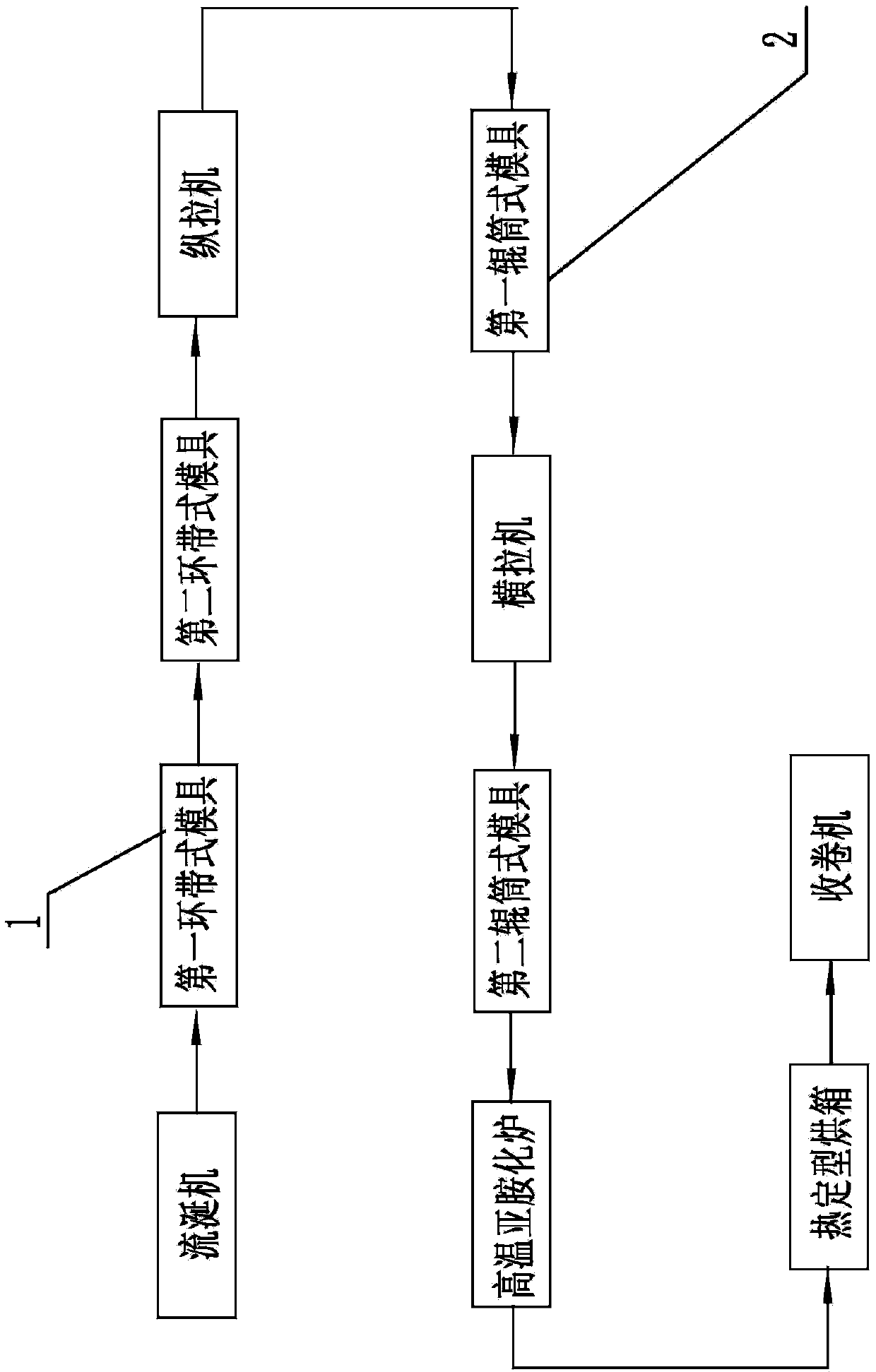

[0029] The embodiment of the polyimide film production line of this improved polyimide film physical properties figure 1 As shown, the equipment from left to right is as follows: salivation machine, first endless belt die 1, second endless belt die, longitudinal drawing machine, first roller die 2, horizontal drawing machine, second roller type mold, high temperature imidization furnace, heat setting oven, cold air box and winder.

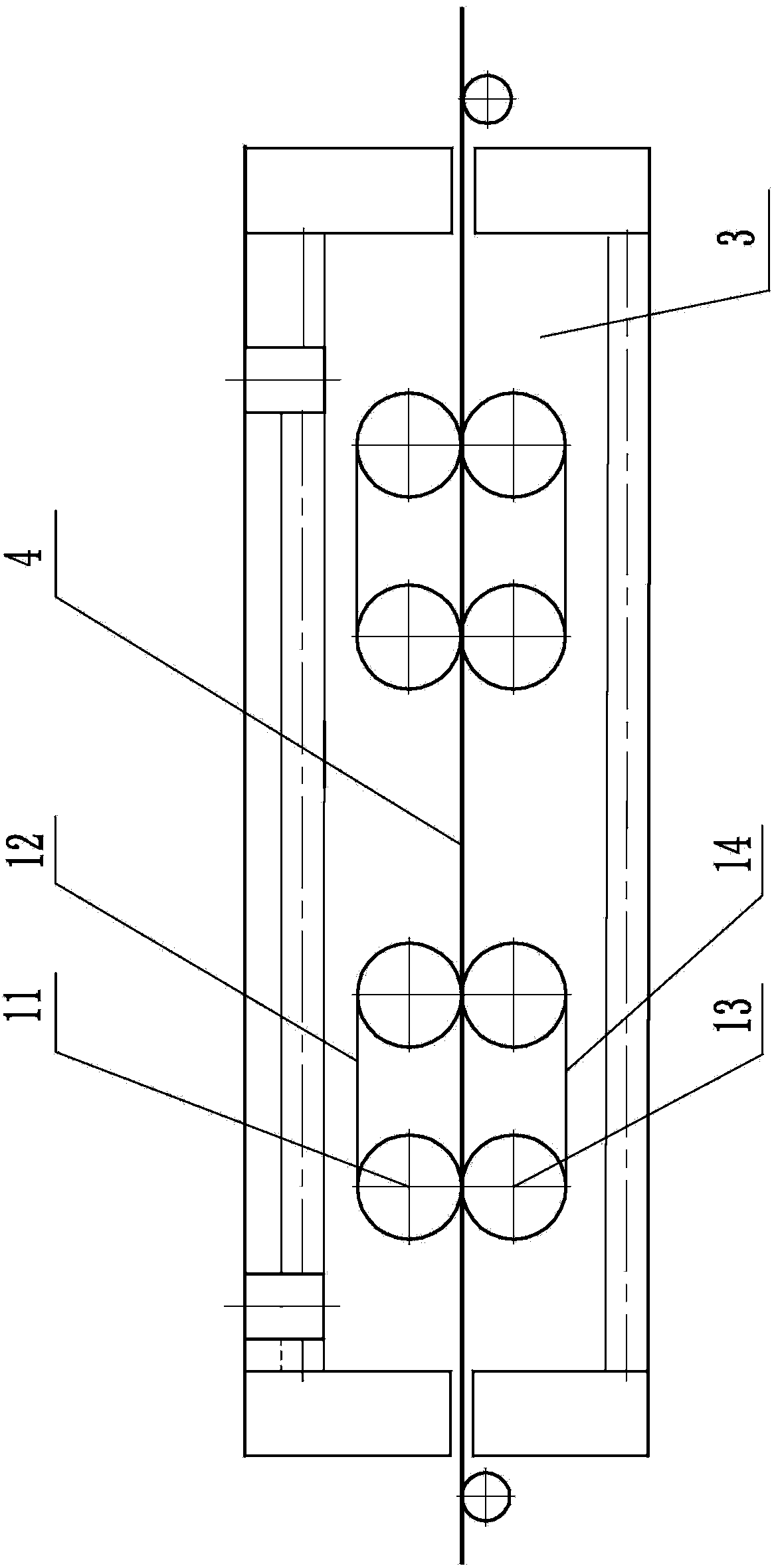

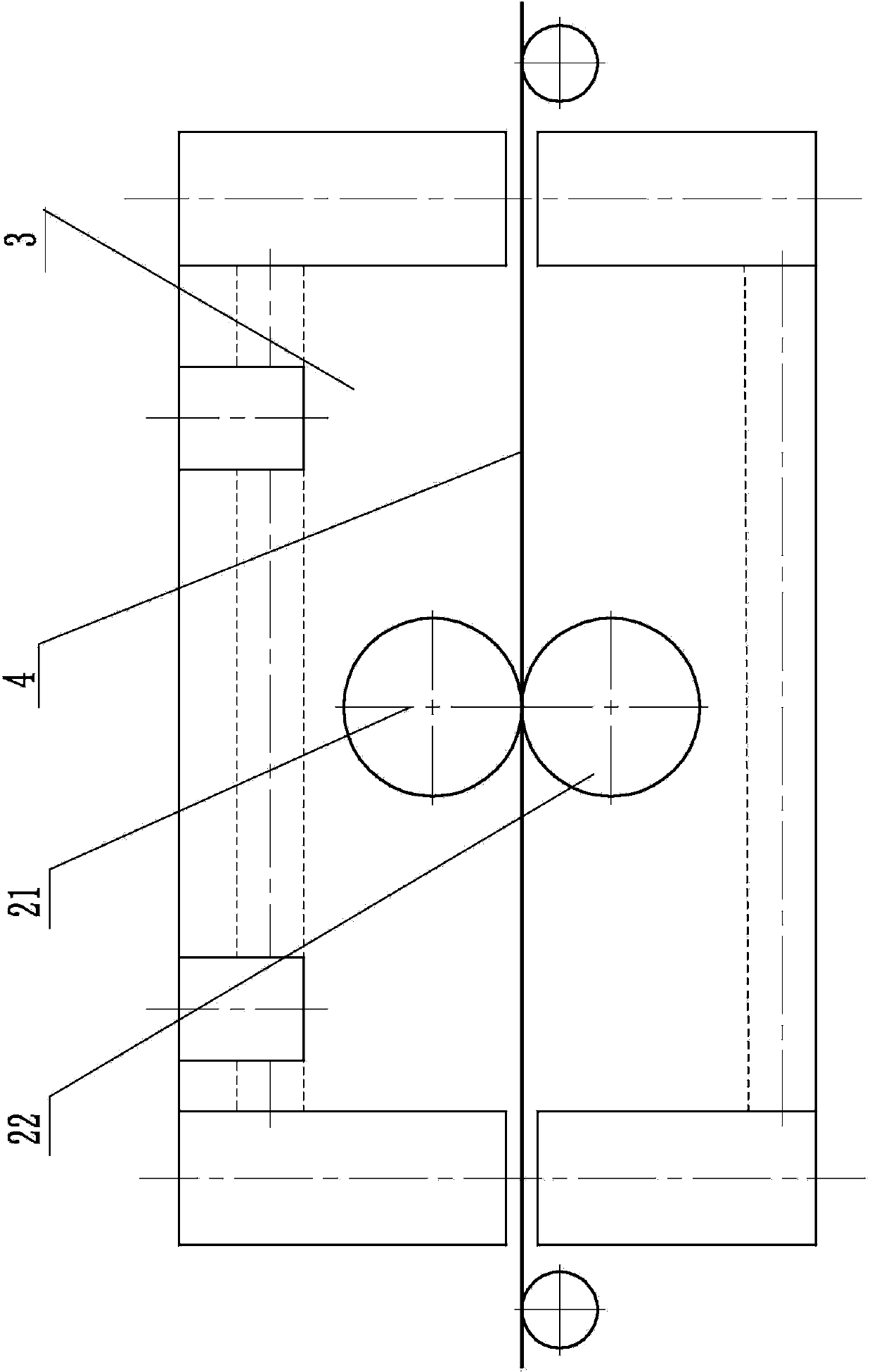

[0030] In this example, 2 sets of belt molds behind the tape casting machine 1 such as figure 2 As shown, the first endless belt mold 1 and the second endless belt mold 1 are in the rolling oven 3, and the temperature in the rolling oven 3 is 145°C. The two sets of endless belt molds 1 are the same, and each set of endless belt molds 1 includes the same upper rolling steel belt 12 and lower rolling steel belt 14 located on and below the film 4 respectively, the upper rolling steel belt 12 runs around two upper rollers 11, and the lower rolling st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com