Barium sulfate diaphragm and preparation method thereof

A technology of barium sulfate and diaphragm, which is applied in the field of barium sulfate diaphragm and its preparation, and can solve the problems of poor adhesion between barium sulfate and the diaphragm surface, decreased air permeability of the diaphragm, and easy powder drop of the barium sulfate layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

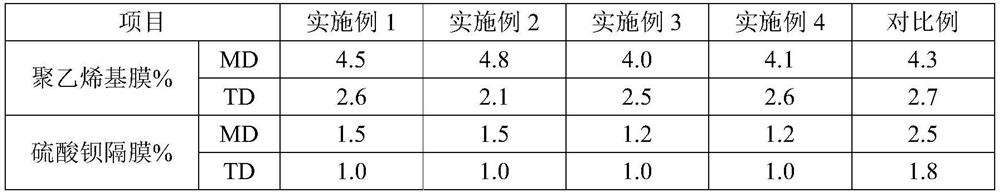

Examples

Embodiment 1

[0055] (1) Preparation of coupling agent modified barium sulfate

[0056] 50 parts of 20nm barium sulfate, 6 parts of sodium chloride, 80 parts of DI water, and 50 parts of ethanol were mixed and stirred at 60° C. for 0.5 h at 1000 rpm to prepare a barium sulfate suspension with a solid content of 30 wt %;

[0057] Add 0.5 parts of titanate coupling agent to the barium sulfate suspension, use a high-speed shear emulsifier, shear and emulsify at 8000rpm / min for 20min to modify the nano-barium sulfate, and then filter, wash, dry, and airflow crush The coupling agent modified barium sulfate powder is obtained.

[0058] After testing, the average particle size of the modified barium sulfate powder is 20nm

[0059] (2) Preparation of barium sulfate slurry

[0060] Mix 8 parts of acrylic acid, 0.5 parts of sodium polyacrylate, and 800 parts of DI water, and stir at 30°C for 20 minutes at 500 rpm / min; then add 80 parts of coupling agent-modified barium sulfate, and stir for 1.5 hou...

Embodiment 2

[0064] (1) Preparation of coupling agent modified barium sulfate

[0065] 60 parts of 20nm barium sulfate, 6 parts of sodium chloride, 50 parts of DI water, and 50 parts of ethanol were mixed and stirred at 65° C. for 0.5 h at 1000 rpm to prepare a barium sulfate suspension with a solid content of 40 wt %;

[0066] Add 1 part of titanate coupling agent to the barium sulfate suspension, use a high-speed shear emulsifier, shear and emulsify at 8000rpm / min for 20min to modify the nano-barium sulfate, and then filter, wash, dry, and airflow crush The coupling agent modified barium sulfate powder is obtained.

[0067] After testing, the average particle diameter of the obtained modified barium sulfate powder is 25nm

[0068] (2) Preparation of barium sulfate slurry

[0069] Mix 10 parts of methacrylic acid, 1 part of polyethylene glycol ether, and 1500 parts of DI water, stir at 30°C for 20 minutes at 500 rpm / min; then add 85 parts of coupling agent-modified barium sulfate, and s...

Embodiment 3

[0073] (1) Preparation of coupling agent modified barium sulfate

[0074] 75 parts of 15nm barium sulfate, 8 parts of sodium chloride, 50 parts of DI water, and 50 parts of ethanol were mixed and stirred at 70° C. for 0.5 h at 1000 rpm to prepare a barium sulfate suspension with a solid content of 45 wt %;

[0075] Add 2 parts of aluminate coupling agent to the barium sulfate suspension, use a high-speed shear emulsifier, shear and emulsify at 10000rpm / min for 20min to modify the nano-barium sulfate, and then filter, wash, dry, and airflow crush The coupling agent modified barium sulfate powder is obtained.

[0076] After testing, the average particle diameter of the obtained modified barium sulfate powder is 25nm

[0077] (2) Preparation of barium sulfate slurry

[0078] Mix 10 parts of methyl acrylate, 1 part of sodium polyacrylate, and 1500 parts of DI water, stir at 30°C for 20 minutes at 500 rpm / min; then add 85 parts of coupling agent-modified barium sulfate, and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com