High weather resistance type release film and preparation method thereof

A release film, high weather resistance technology, applied in the direction of film/sheet release liners, adhesives, etc., can solve the problems of viscosity change and release film release force change, etc., to achieve easy peeling and improve peeling stability. , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

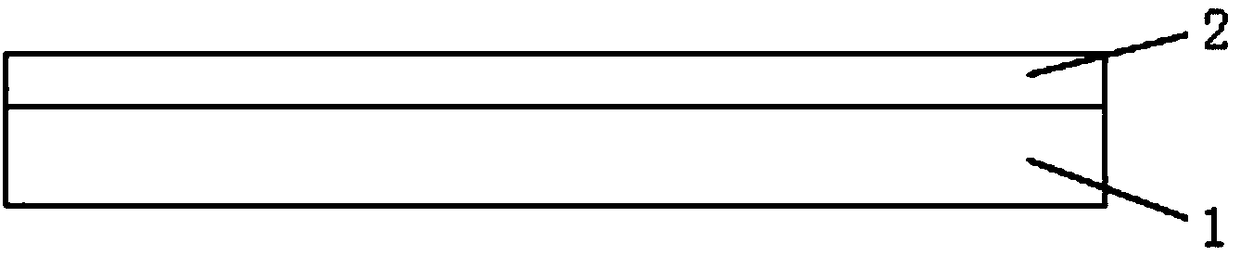

Image

Examples

Embodiment 1

[0022] A preparation formula for high weather resistance release film, release agent 2 includes the following raw materials in mass fraction ratio: silicone oil main agent (100 parts), silicon hydrogen crosslinking agent (0.5 part), silane coupling agent (1 part) , platinum catalyst (3 parts), ethyl acetate (200 parts), butanone (200 parts), solvent gasoline (500 parts), isopropanol (50 parts);

Embodiment 2

[0024] A formula for preparing a high weather-resistant release film, the release agent 2 includes the following raw materials in mass fraction proportions: silicone oil main agent (100 parts), silicon hydrogen crosslinking agent (1 part), silane coupling agent (0.5 part) , platinum catalyst (5 parts), ethyl acetate (200 parts), butanone (200 parts), solvent gasoline (500 parts), isopropanol (50 parts).

Embodiment 3

[0026] Release agent 2 comprises silicone oil main agent (100 parts), silicon hydrogen crosslinking agent (0 part), silane coupling agent (0.5 part), platinum catalyst (5 parts), ethyl acetate (200 parts), butanone ( 200 parts), solvent gasoline (500 parts), isopropanol (50 parts).

[0027] A method for preparing a high-weather-resistant release film, comprising the steps of:

[0028] Step 1: Weigh all the ethyl acetate, methyl ethyl ketone, isopropanol and part of solvent gasoline according to the proportion, pour them into the container, dissolve and stir evenly, and let it stand properly after mixing evenly;

[0029] Step 2: Weigh all the silicone oil main agent and pour it into the solvent after mixing in S1 to dissolve and stir evenly;

[0030] Step 3: Weigh all the silicon hydrogen crosslinking agent and pour it into the mixed solvent in S2 to dissolve and stir evenly;

[0031] Step 4: Weigh all the silane coupling agent and pour it into the mixed solvent in S3 to diss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com