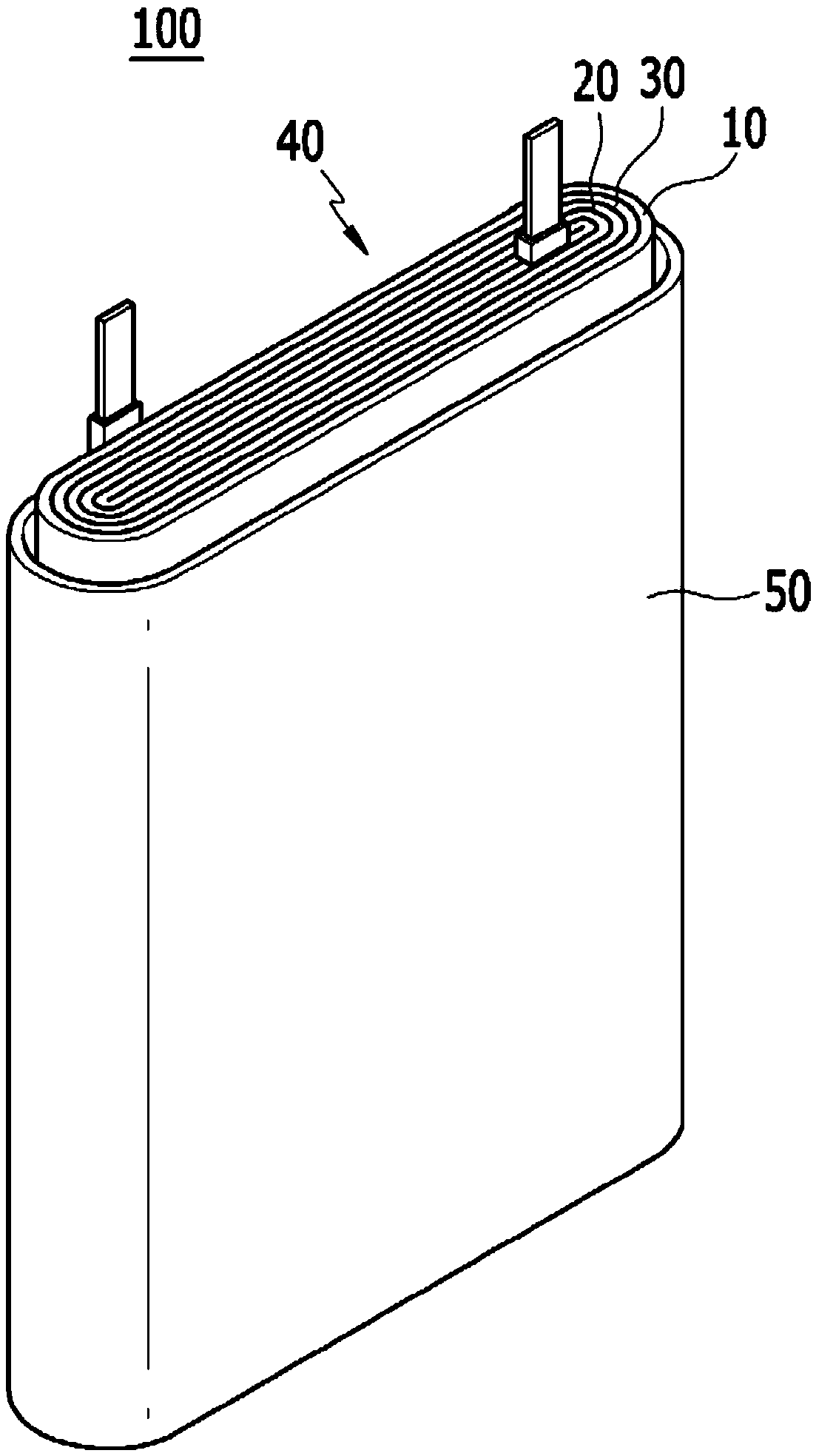

Separator comprising porous adhesive layer, and lithium secondary battery using same

A technology of adhesive layer and separator, which is applied in the direction of secondary batteries, battery components, circuits, etc., can solve the problems of increasing the air permeability of the separator, easy deterioration of battery charging and discharging characteristics, and insufficient shape stability of the battery. , to achieve the effect of increasing the air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

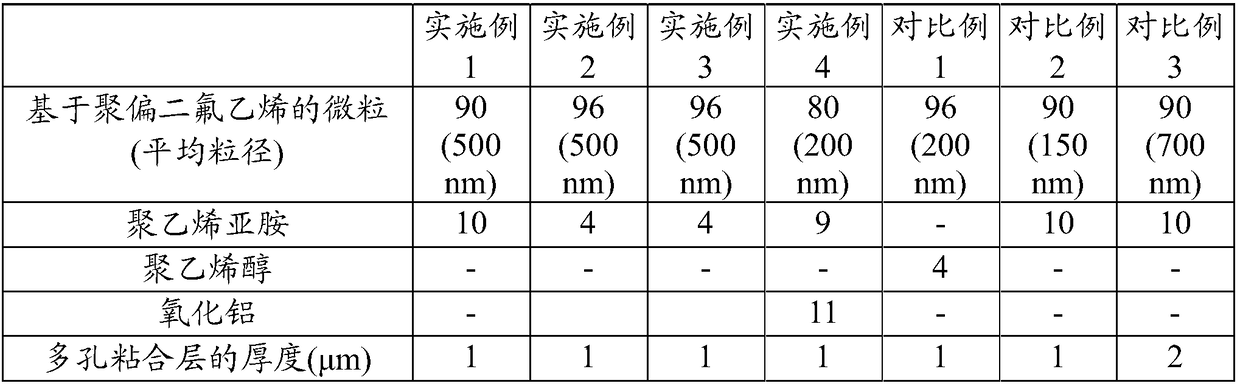

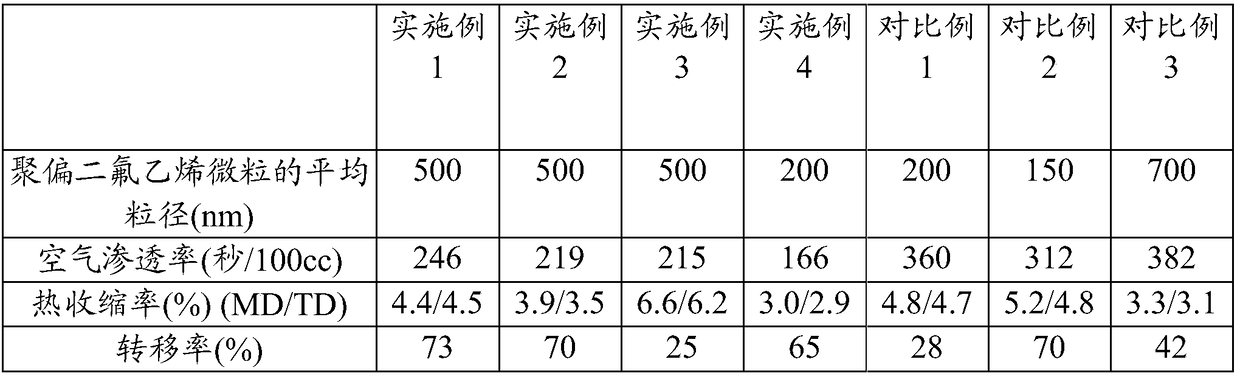

Embodiment 1

[0082] Preparation of the first porous adhesive layer composition

[0083] By mixing polyvinylidene fluoride homopolymer (weight average molecular weight: 450000 g / mol, XPH-838, Solvey) in water to 25 wt%, and using a stirrer (R010, I.K Co., Ltd.) The mixture was stirred for 2 hours to prepare a first polymer solution including polyvinylidene fluoride-based polymer microparticles having an average particle diameter of 500 nm. On the other hand, the second polymer was prepared by mixing polyethyleneimine (weight-average molecular weight: 70000 g / mol, P-1050, Epomin) with water to 7 wt%, and stirring the mixture with a stirrer at 25°C for 2 hours. substance solution. 25wt% of the first polymer solution and 7wt% of the second polymer solution were mixed to have a weight ratio of 9:1 between polyvinylidene fluoride-based polymer particles and polyethyleneimine, and then, at 25 °C for 30 minutes with a stirrer to prepare a first porous adhesive layer composition.

[0084] Pa...

Embodiment 2

[0087] Preparation of the second porous adhesive layer composition

[0088] In addition to mixing 25 wt% of the first polymer solution and 7 wt% of the second polymer solution to have a weight ratio of 9.6:0.4 between polyvinylidene fluoride-based polymer particles and polyethyleneimine, according to The second porous adhesive layer composition was prepared in the same manner as in Example 1.

[0089] Partition manufacturing

[0090] A separator having a total thickness of 10 μm according to Example 2 was manufactured in the same manner as in Example 1 except that the second porous adhesive layer composition was used instead of the first porous adhesive layer composition of Example 1.

Embodiment 3

[0092] Preparation of the third porous adhesive layer composition

[0093] A third porous adhesive layer composition was prepared in the same manner as the preparation of the second porous adhesive layer composition according to Example 2.

[0094] Partition manufacturing

[0095] Except that the third porous adhesive layer composition was used instead of the first porous adhesive layer composition of Example 1 and the third porous adhesive layer composition was coated on one surface of the polyethylene film instead of on its A separator having a total thickness of 10 μm according to Example 3 was produced in the same manner as in Example 1 except on both surfaces.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com