Separator for electrochemical device and electrochemical device containing same

An electrochemical and separator technology, used in electrochemical generators, hybrid capacitor separators, battery electrodes, etc., can solve the problems of porous polymer substrate damage, high wear, separator damage, etc., to improve the thermal shrinkage rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] As used herein, the terms "about", "substantially" or similar terms are used as a starting point from or adjacent to a specified value when acceptable manufacturing and material tolerances specific to the stated meaning are suggested. and are used for the purpose of preventing undue use by irresponsible offenders of the disclosure, including precise or absolute values, which are provided to aid in the understanding of the disclosure.

[0052] As used herein, the term "their combination" included in any Markush-type expression refers to a combination or mixture of one or more elements selected from the group of elements disclosed in the Markush-type expression , and refers to the presence of one or more elements selected from this group.

[0053] As used herein, the expression "A and / or B" means "A, B, or both".

[0054] In order to solve the safety-related problems of electrochemical devices such as lithium secondary batteries, a separator has been proposed, which cons...

Embodiment 1

[0125] 1) Manufacture of anode

[0126] Artificial graphite, carbon black, carboxymethylcellulose (CMC, carboxymethylcellulose) and styrene-butadiene rubber (SBR, Styrene Butadiene Rubber) as the anode active material were introduced into water at a weight ratio of 96:1:2:2 and mixed therein , to prepare anode slurry. The anode slurry was coated at a capacity of 3.55 mAh / g onto a copper foil (Cu-foil) with a thickness of 50 μm as an anode current collector to form a thin electrode plate, which was then dried at 135° C. for 3 hours or longer, and then pressed (pressing) to obtain the anode.

[0127] 2) Manufacture of cathode

[0128] LiNi as the cathode active material 0.6 co 0.2 mn 0.2 o 2 , carbon black, and polyvinylidene fluoride (PVdF, Polyvinylidene Fluoride) were introduced into N-methyl-2-pyrrolidone at a weight ratio of 96:2:2 and mixed therein to prepare a cathode slurry. The cathode slurry was coated at a capacity of 3.28 mAh / g on an aluminum foil having a thi...

Embodiment 2 and 3

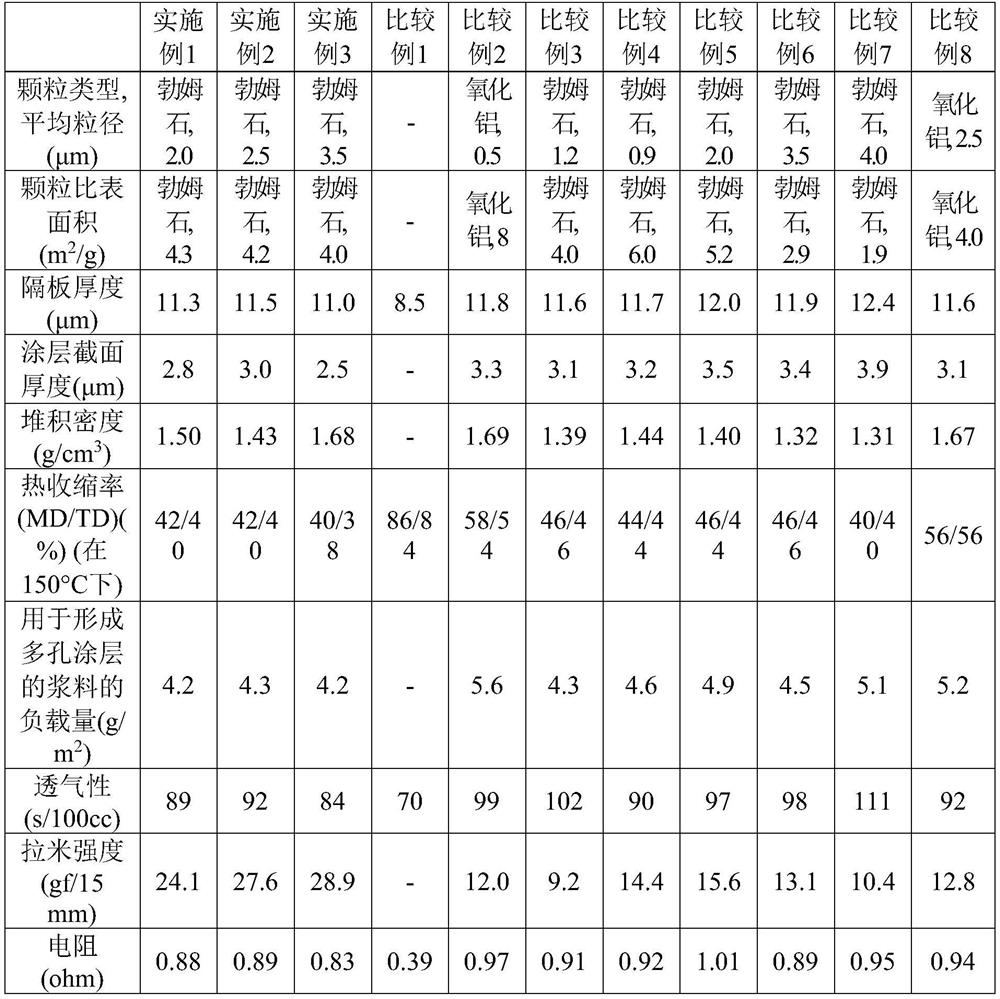

[0135] An electrode assembly was obtained in the same manner as in Example 1, except that the average particle diameter and specific surface area of the boehmite particles were controlled as shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com