Method for producing separation membrane, and said separation membrane and battery using same

A separator and electrochemical technology, which is applied in the field of electrochemical batteries, can solve the problems of inability to apply matrix membranes and limitations of matrix membrane components, and achieve the effects of improving stability, suppressing internal short circuits, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

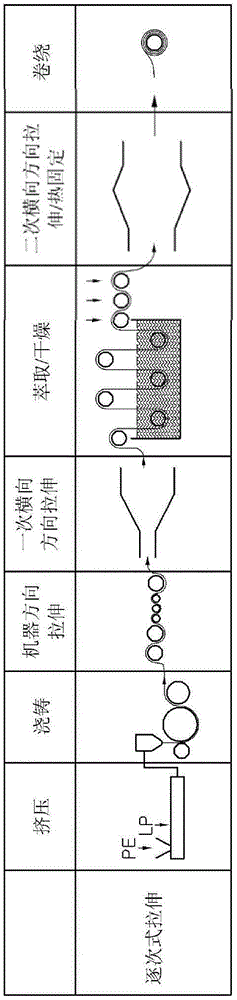

Method used

Image

Examples

example 1

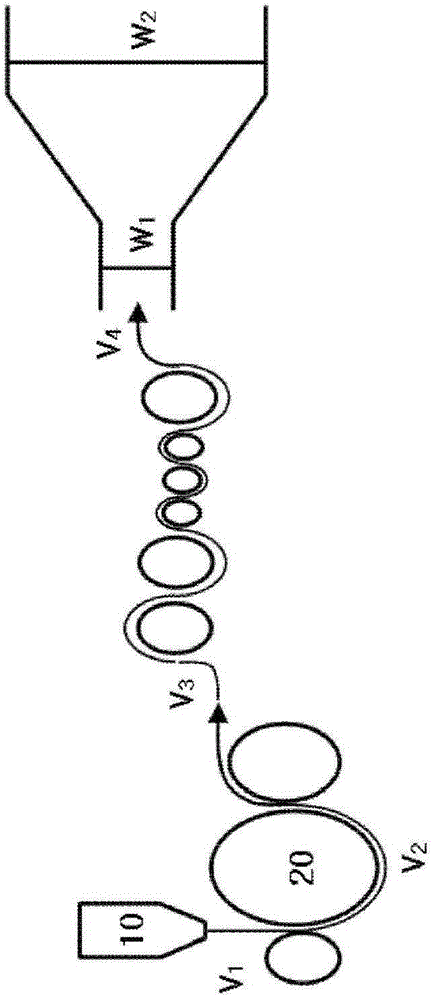

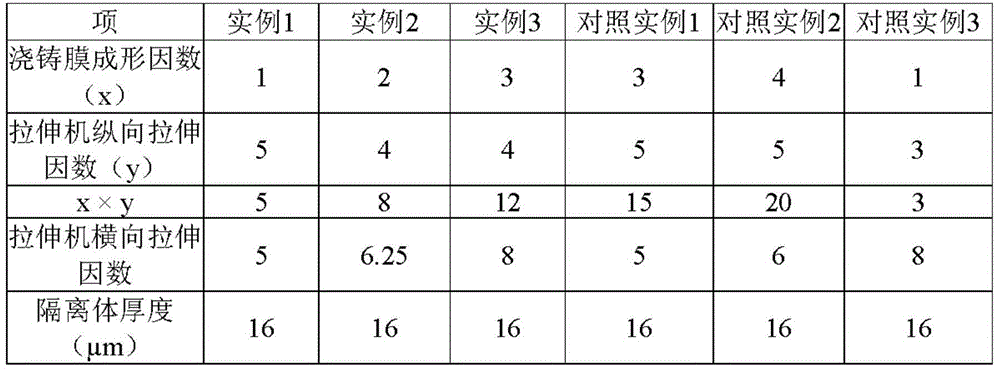

[0106] 30 parts by weight of high-density polyethylene (High-density polyethylene, HDPE; Mitsui Chemical) having a weight average molecular weight (Mw) of 600,000 g / mol was supplied into a twin-screw extruder, and then 70 parts by weight Parts of fluid paraffin (Ace West Chemical Co.) were introduced into a twin-screw extruder, followed by extrusion.

[0107] After extrusion, the gel phase obtained by the T-die is fabricated into a separator in the form of a sheet using chilled rolls. When making a sheet, casting is performed by adjusting the speed of the cooling roll so that the film forming factor of the casting device is 1. Next, the sheet was stretched so that the stretching machine longitudinally stretched by a factor of 5, and then stretching was performed once on the sheet so that the stretching machine transversely stretched by a factor of 5.

[0108] The stretched polyethylene matrix film was washed with dichloromethane (Samsung Fine Chemicals) to extract fluid paraf...

example 2

[0110] A polyolefin porous separator was prepared in the same manner as in Example 1, except that the film forming factor of the casting equipment, the longitudinal stretch factor of the stretcher, and the transverse stretch factor of the stretcher were set to 2, 4, and 6.25, respectively.

example 3

[0112] A polyolefin porous separator was prepared in the same manner as in Example 1, except that the film forming factor of the casting equipment, the longitudinal stretch factor of the stretcher, and the transverse stretch factor of the stretcher were set to 3, 4, and 8, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com