Patents

Literature

40results about How to "Uniform tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermosetting resin composition and its article

InactiveUS20070191555A1Low dielectric constantUniform tensile strengthCircuit susbtrate materialsDielectric lossEpoxide

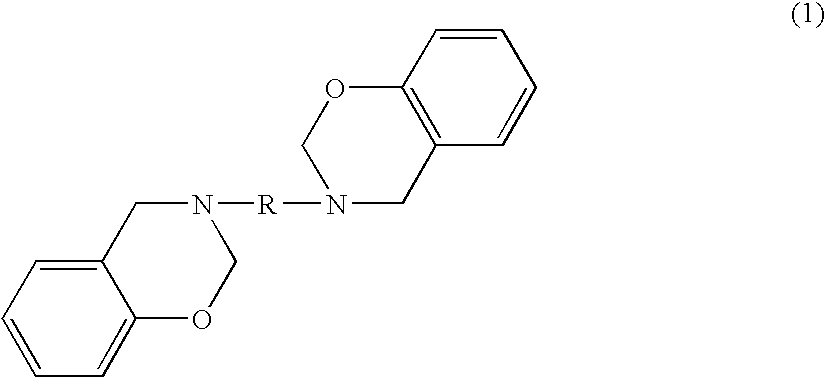

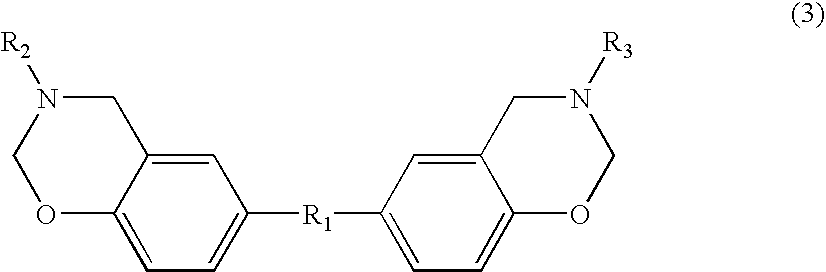

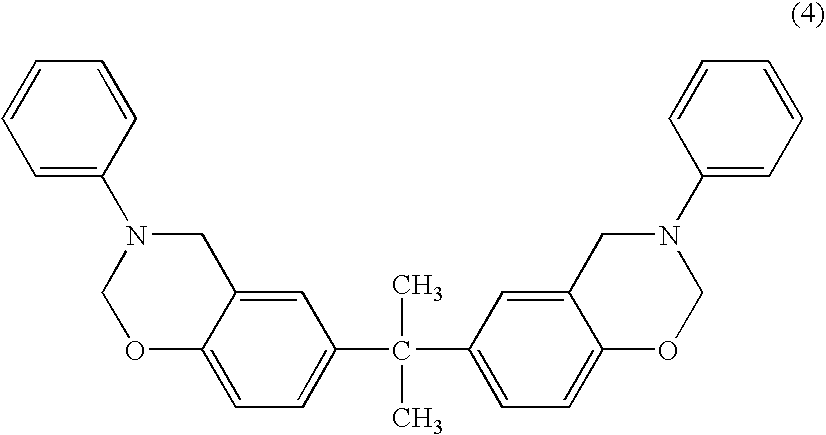

The invention provides a thermosetting resin composition comprising a bifunctional dihydrobenzoxazine compound and an epoxy compound, and provides a thermosetting resin molding obtained by thermally curing the thermosetting resin composition. The molding has excellent electric properties of low dielectric constant and low dielectric loss tangent. The resin composition comprises an epoxy compound and a bifunctional dihydrobenzoxazine compound of the following general formula (1), wherein the equivalent ratio of the epoxy compound to the bifunctional dihydrobenzoxazine compound is 1 / (0.1 to 20): wherein R represents a linear alkylene group having at least 2 carbon atoms, or a branched alkylene group derived from it by substituting the hydrogen atom therein with an alkyl group, and the hydrogen atom of the benzene ring may be substituted with an alkyl group or an alkoxy group.

Owner:SEKISUI CHEM CO LTD

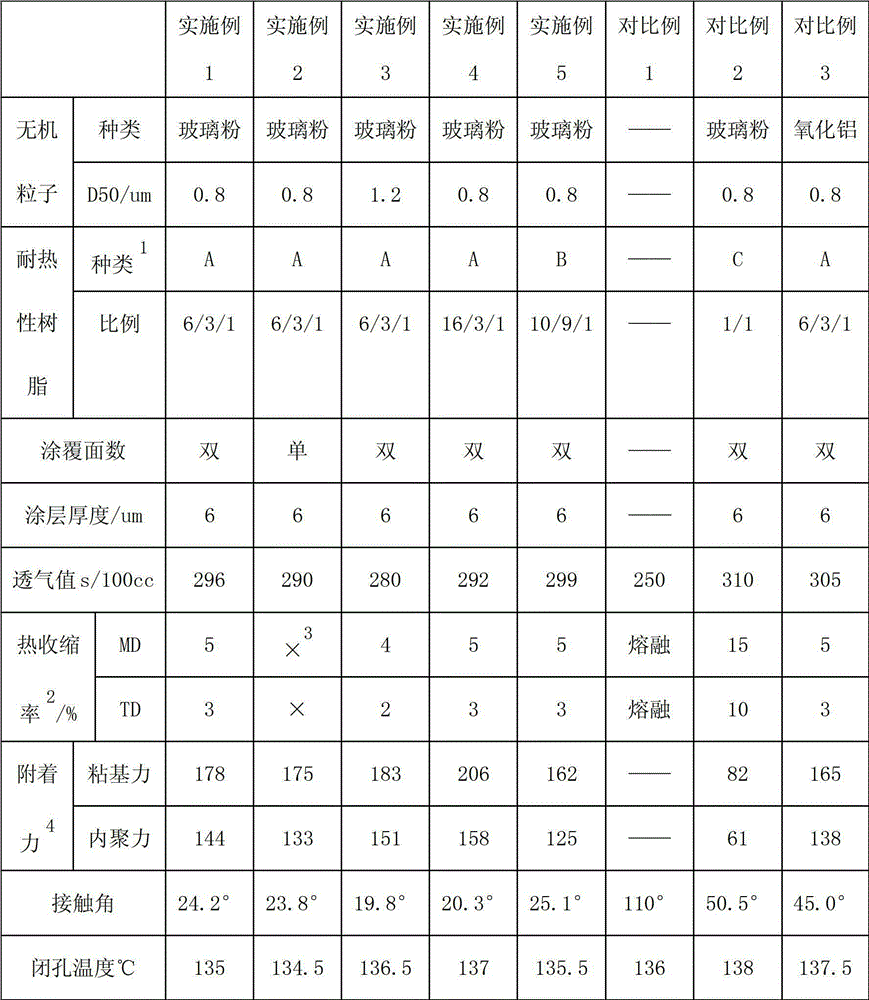

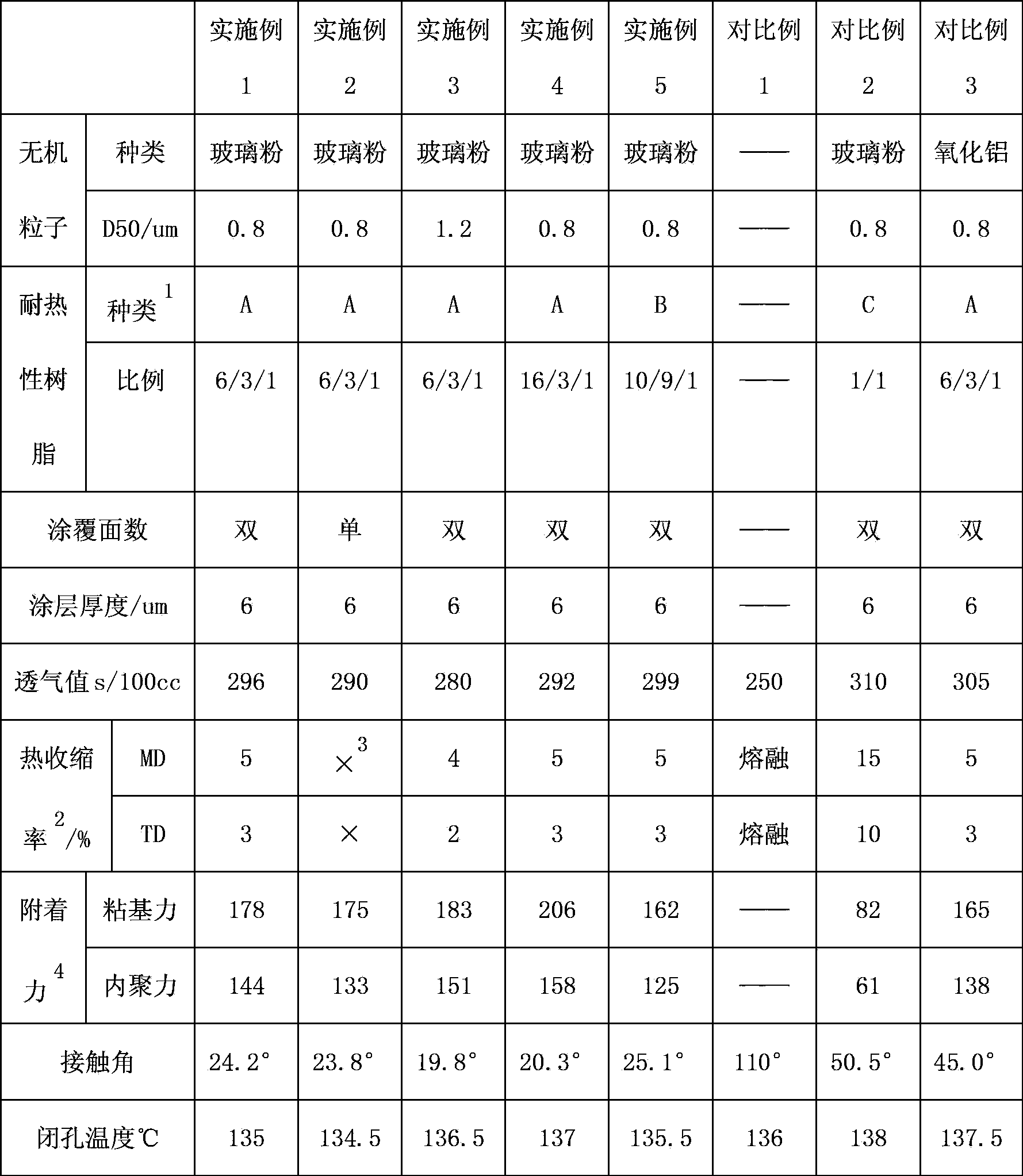

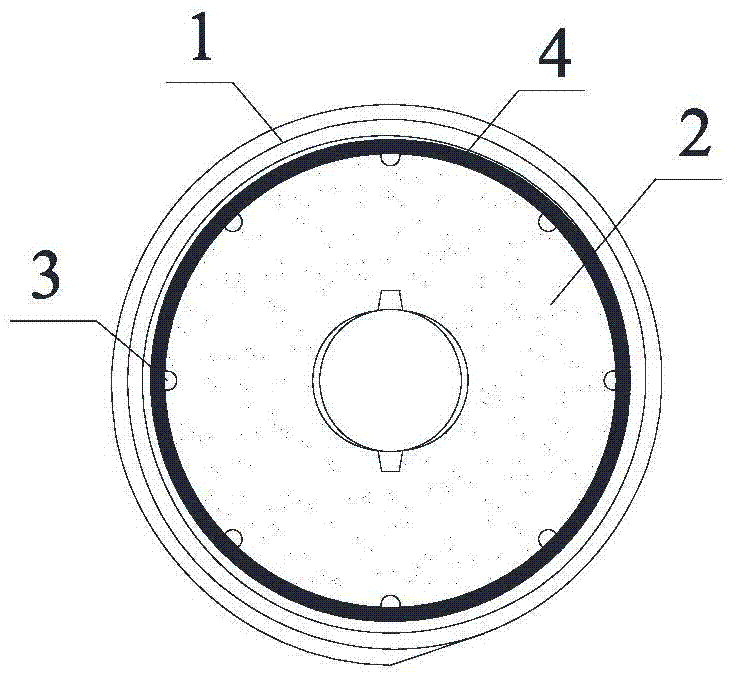

Coating composite for lithium ion secondary battery membrane and method for manufacturing membrane

ActiveCN102942831AHigh temperature resistantLow densityCell seperators/membranes/diaphragms/spacersSecondary cellsCoated surfaceLithium

The invention discloses a coating composite for a lithium ion secondary battery membrane and a method for manufacturing the membrane. The coating composite comprises heat resistant resins and inorganic non-conducting insulation particles, molecular chains of the heat resistant resins comprise oleophylic structural units, hydrophilic structural units and functional group structural units, and a thermal decomposition temperature is larger than 250 DEG C. The inorganic non-conducting insulation particles have the advantages of being high temperature resistant, low in density, rigidity and water absorption and the like; composite micro porous membranes prepared through the coating composite has the advantages of being low in hole closing temperature, high in membrane breaking temperature, low in thermal shrinkage rate, high in combining force between a heat resistant coating and a substrate, good in wettability of the heat resistant coating surface and the like simultaneously; and the membrane used for manufacturing a lithium ion secondary battery has good comprehensive properties and reliable safety performances.

Owner:河南惠强新能源材料科技股份有限公司

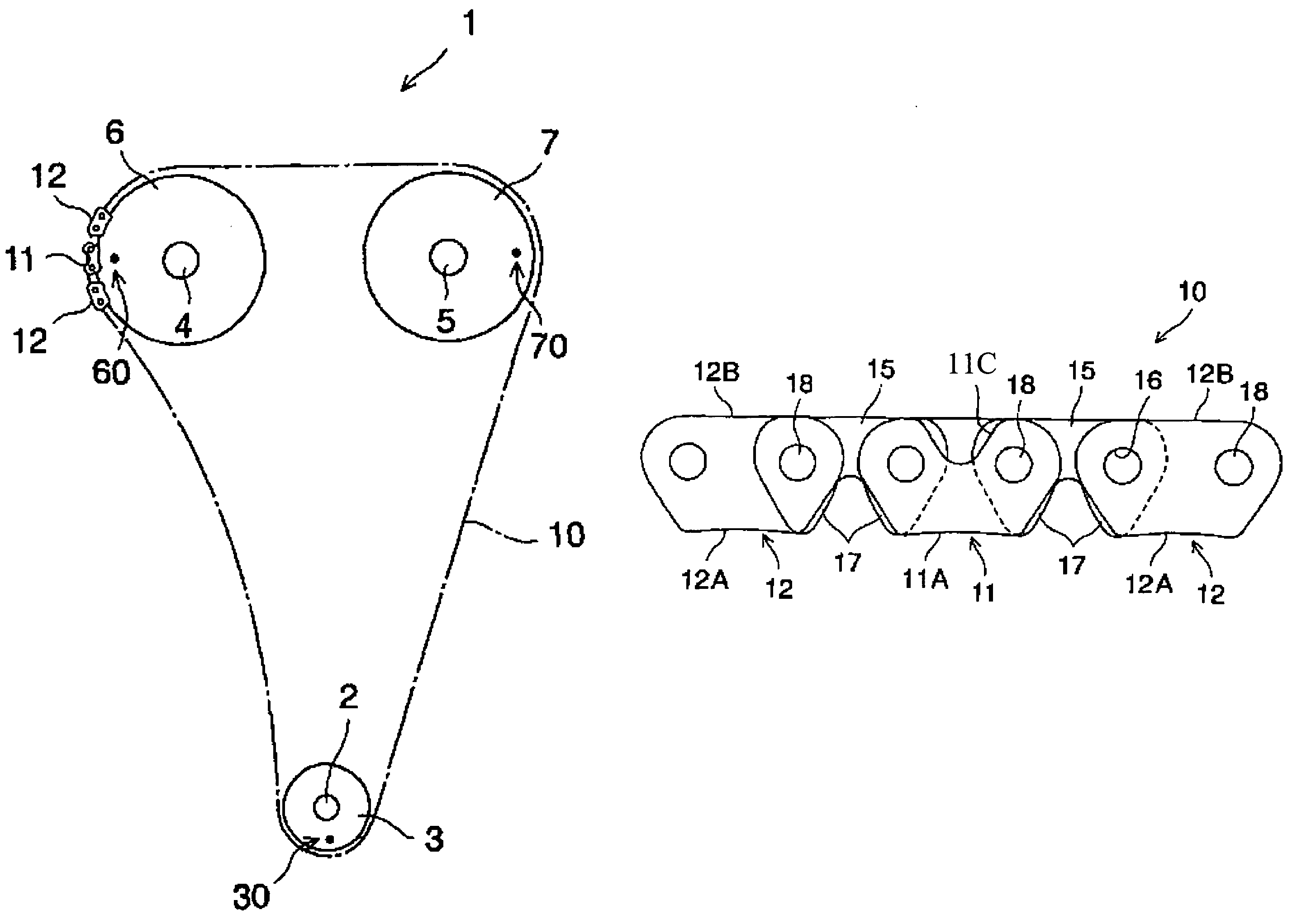

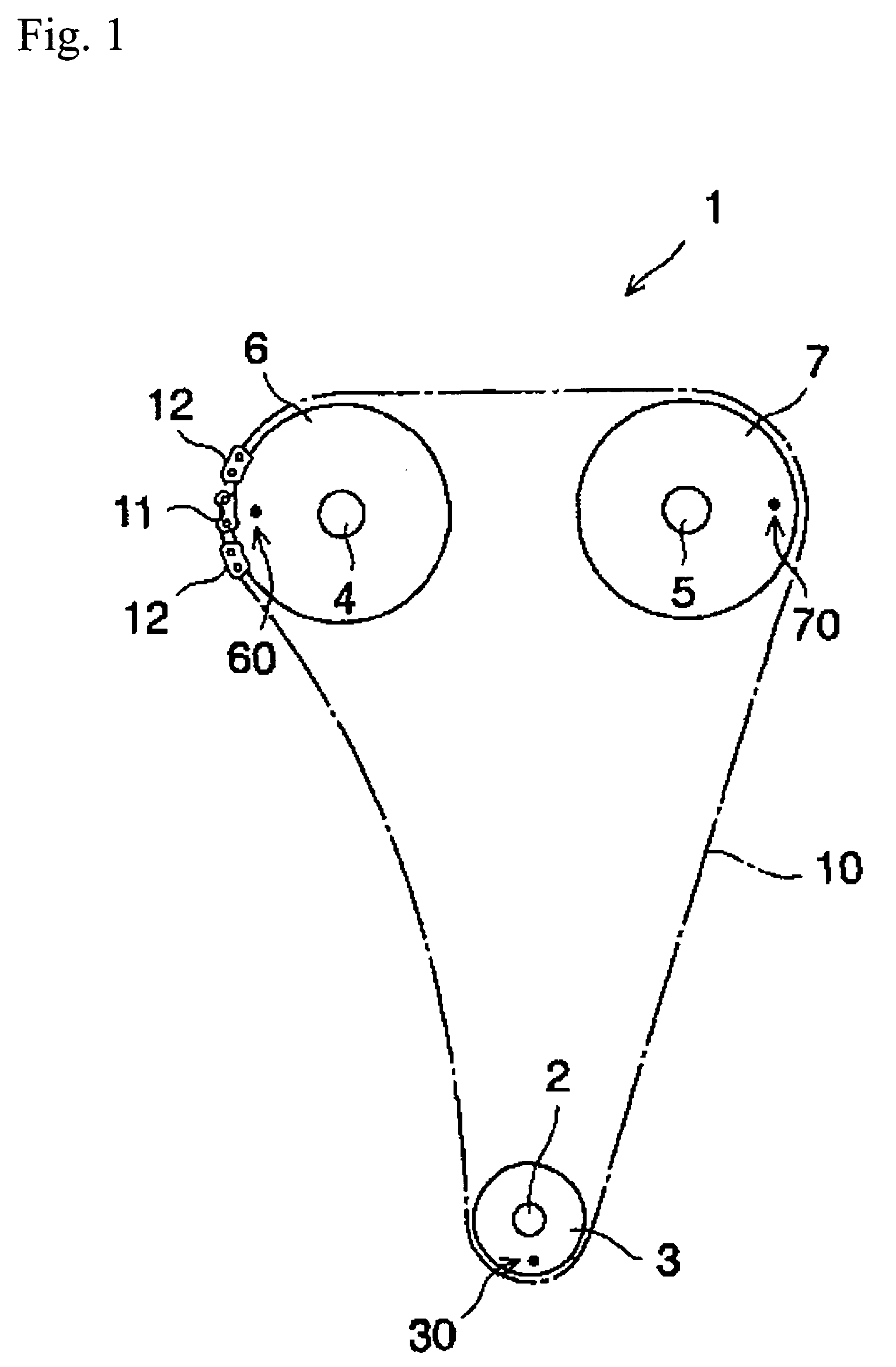

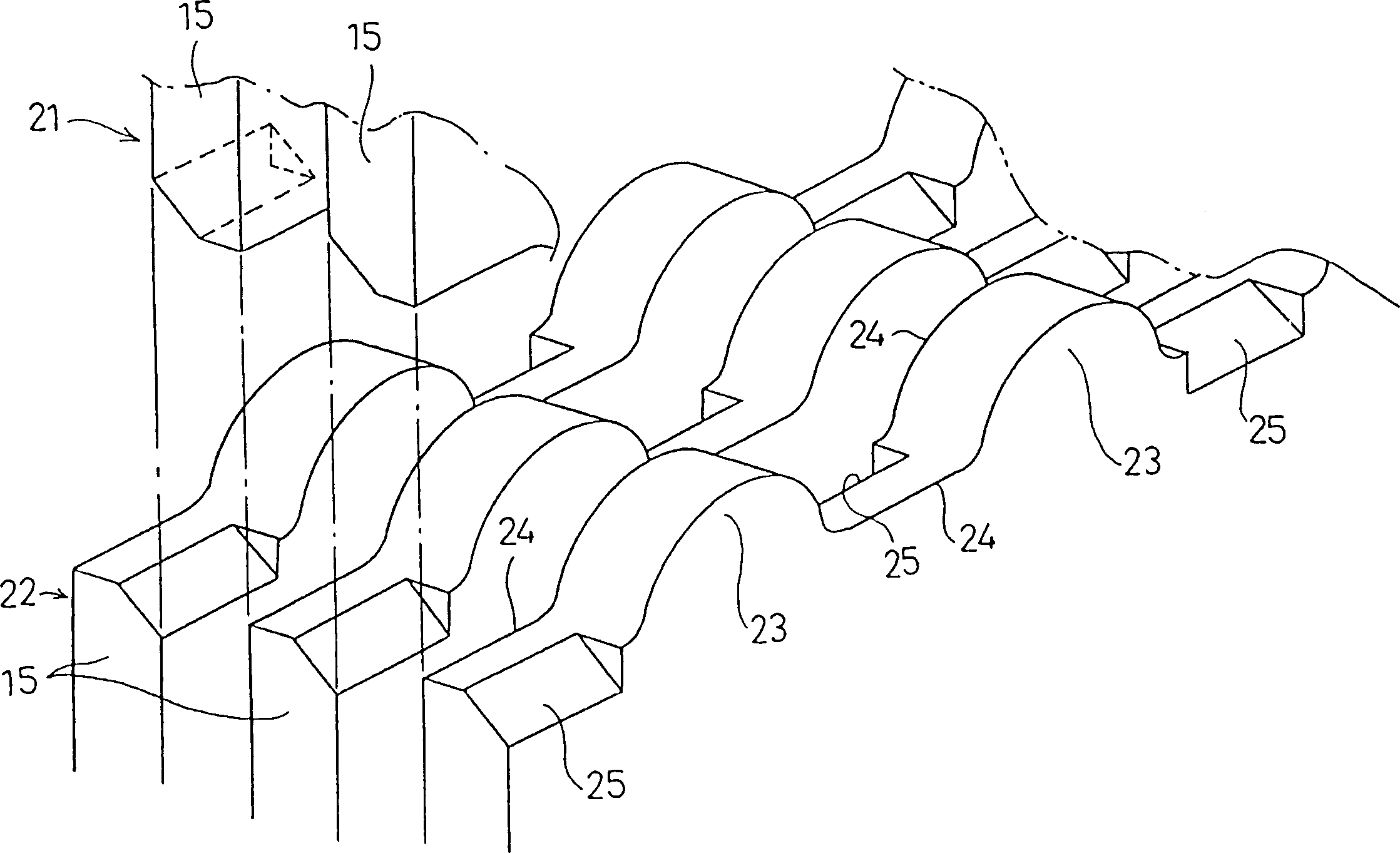

Chain with a mark

A chain for driving and engagement of at least one sprocket including plurality of interlaced link plates and a plurality of guide plates. The link plates are pivotably connected by connecting pins. The plurality of guide plates are disposed along the link plates and guide the chain on the sprocket in a width direction. At least one of the guide plates has a flat portion and a crotch portion and is in line with a marked position on the sprocket.

Owner:BORG WARNER MORSE TEC JAPAN KK

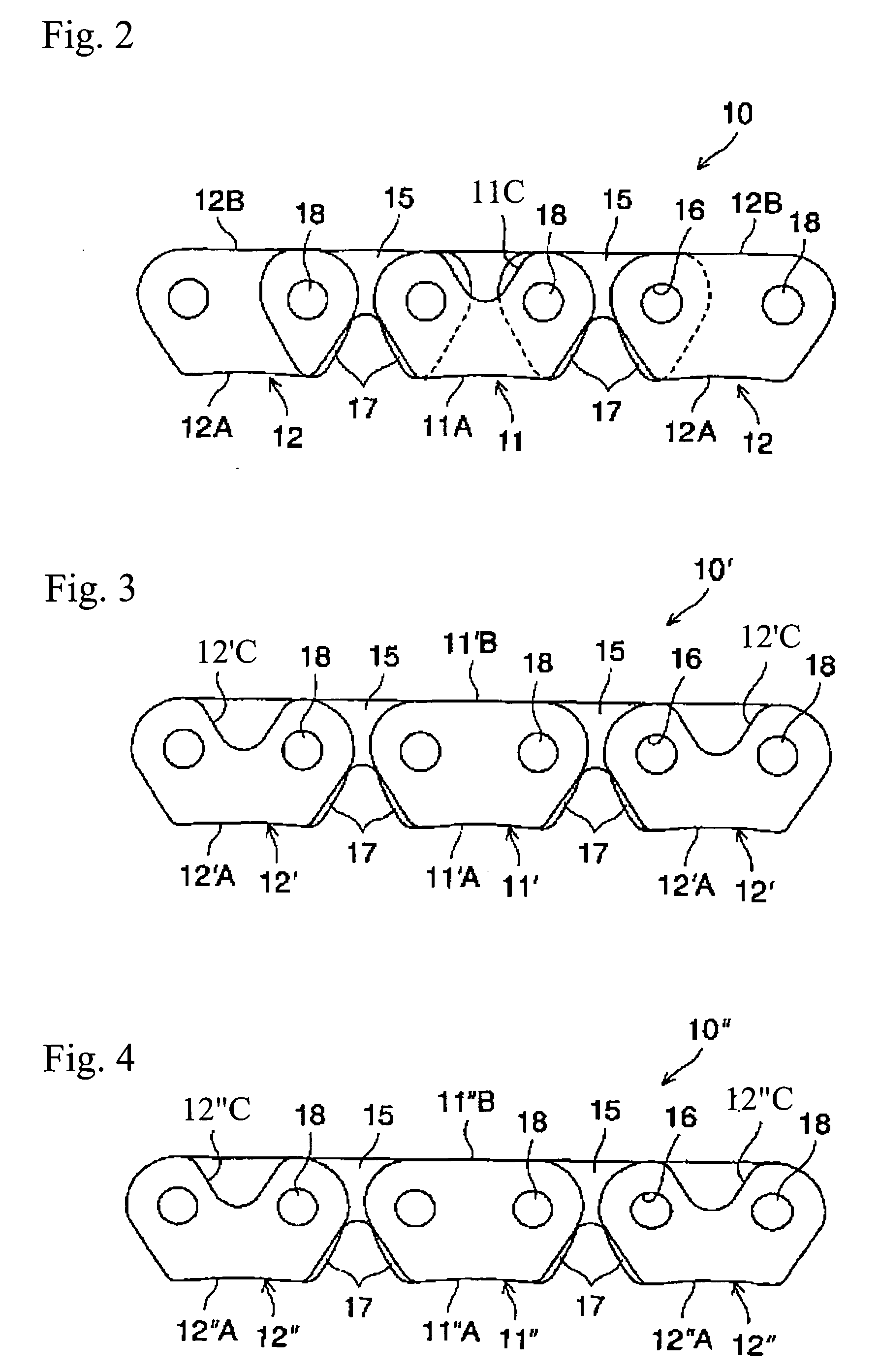

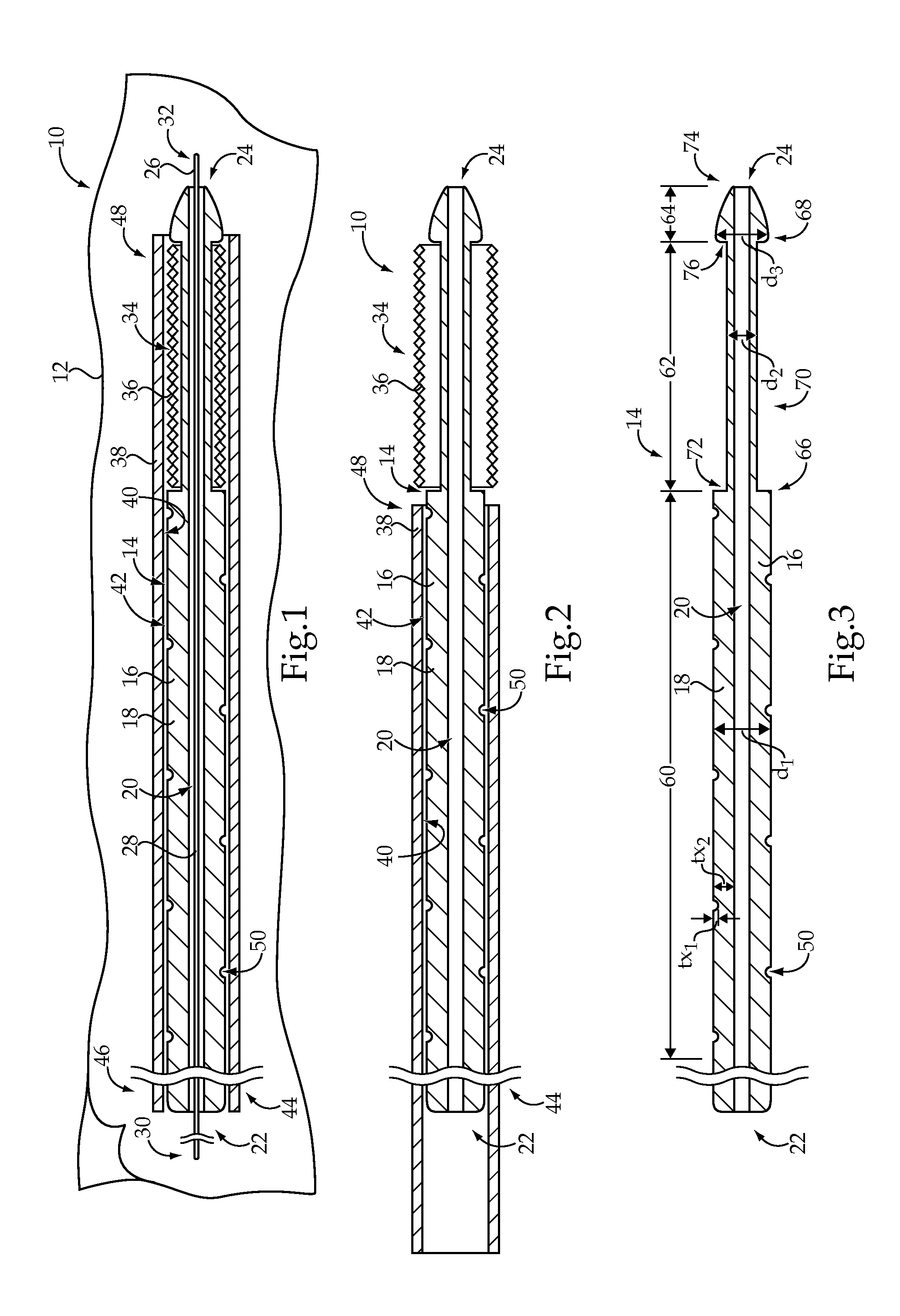

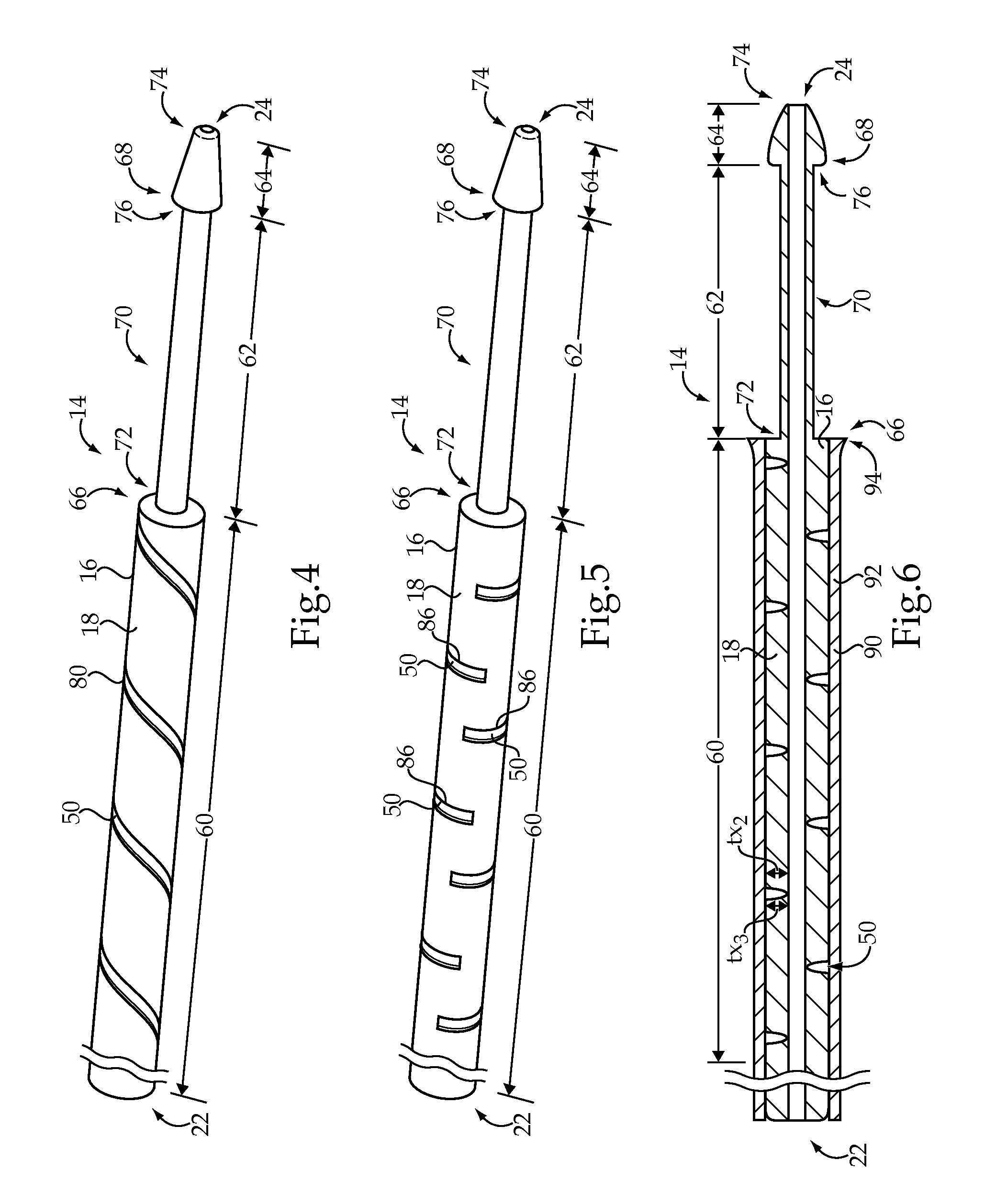

Medical device delivery catheter and medical device delivery system using same

A medical device delivery catheter includes an elongate tubular body including proximal, intermediate, and distal longitudinal segments. The proximal segment extends between a proximal end of the body and a first transition between the proximal segment and the intermediate segment, has a first outer diameter, and includes at least one flexibility increasing cut through a wall of the body. The intermediate segment extends between the first transition and a second transition between the intermediate segment and the distal segment, has a second outer diameter that is less than the first outer diameter, and defines a medical device support region. The distal segment has an initial outer diameter that is greater than the second outer diameter and terminates in a distally tapered region. The body is free of joints and has a uniform tensile strength across the proximal, intermediate, and distal segments and the transitions.

Owner:COOK MEDICAL TECH LLC

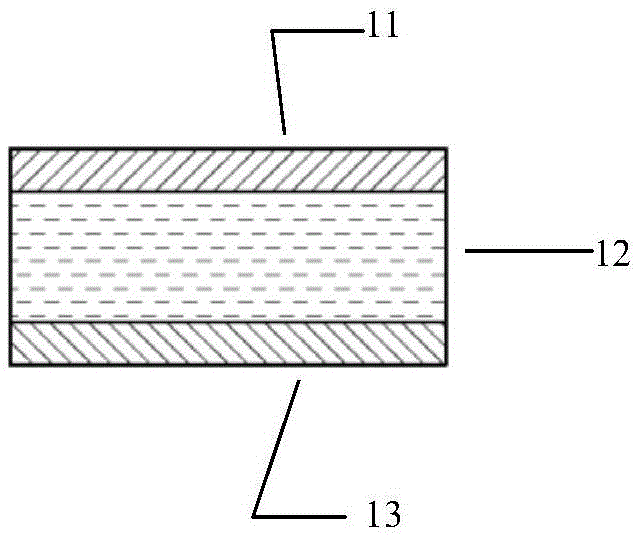

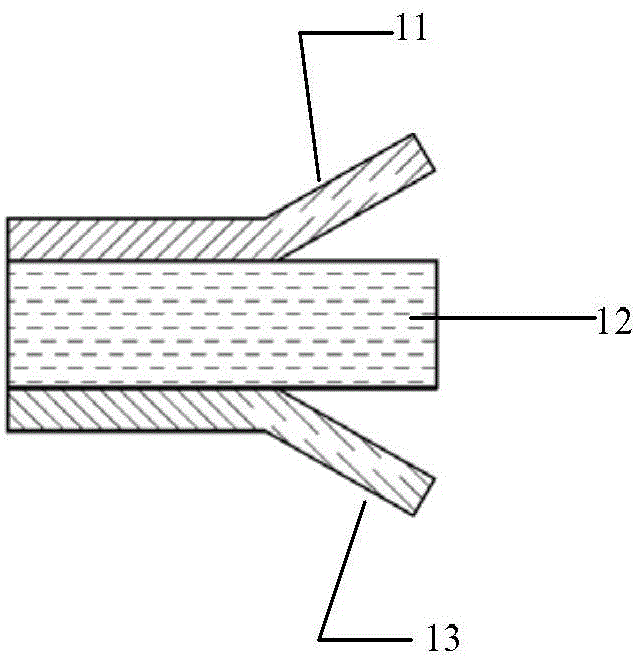

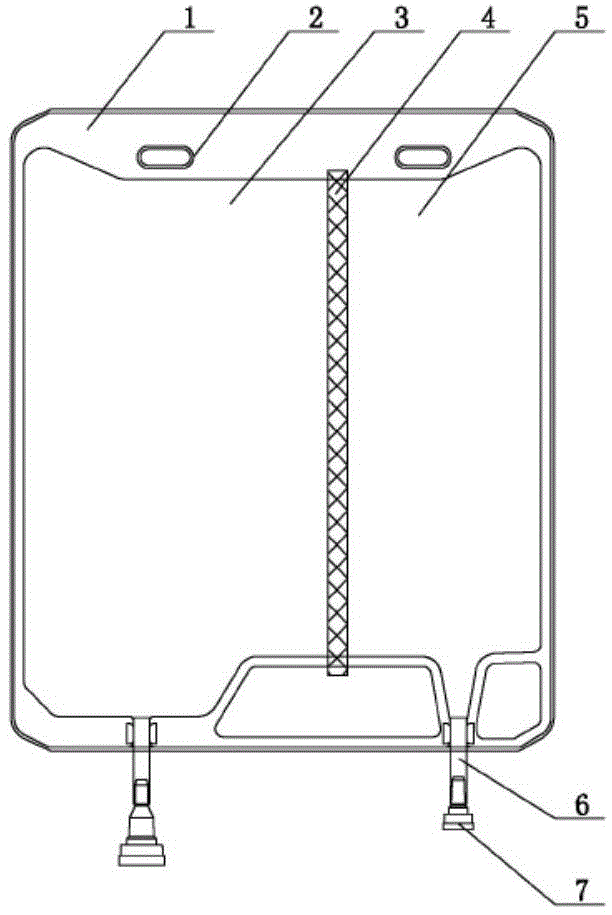

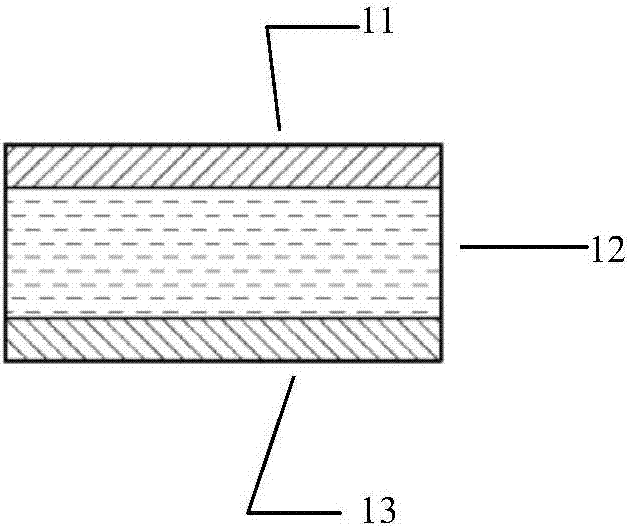

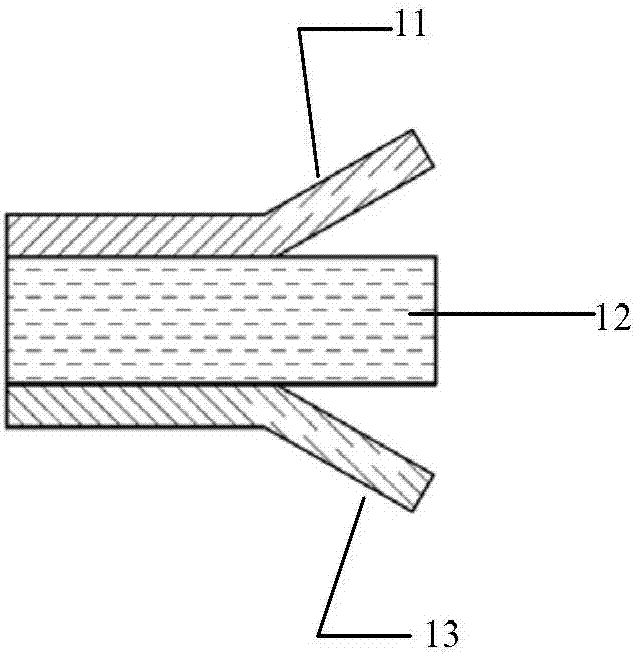

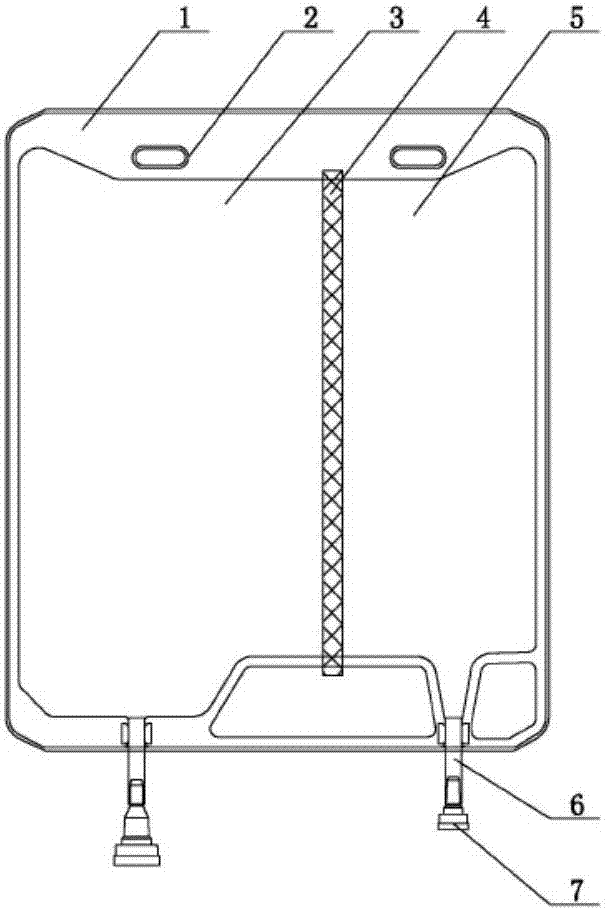

Membrane material for transfusion soft bag and application of membrane material

ActiveCN104354417AEnsure safetyGuaranteed validitySynthetic resin layered productsPharmaceutical containersWaxThermoplastic

The invention relates to a membrane material for a transfusion soft bag and application of the membrane material. The membrane material is obtained by at least co-extruding an outer layer material, a middle layer material and an inner layer material, wherein the outer layer material comprises PP (Polypropylene), PE (Polyethylene) and SEBS (Styrene-Ethylene-Butadiene-Styrene segmented copolymer), wherein the PP accounts for 60wt%-99wt%, the PE accounts for 0.5wt%-30wt% and the SEBS accounts for 0.2wt%-20wt%; the middle layer material comprises PP, PE and SEBS, wherein the PP accounts for 20wt%-90wt%, the PE accounts for 0.5wt%-20wt% and the SEBS accounts for 0.2wt%-65wt%; and the inner layer material comprises PP, SEBS, TPO (Thermoplastic Polyolefin) and polyolefin wax, wherein the PP accounts for 37wt%-99wt%, the SEBS accounts for 0.1wt%-30wt%, the TPO accounts for 0.2wt%-9wt% and the polyolefin wax accounts for 0.1wt%-7wt%. The membrane material for the transfusion soft bag does not contain PVC (Polyvinyl Chloride) or DEHP (Diethylhexyl Phthalate) and a heat transfer film can be used for printing words or coating colors and printing; the membrane material for the transfusion soft bag has good low-temperature resistance falling performance and separation performance; and a false welding connection part can be formed in the inner layer to prepare the multi-chamber transfusion soft bag.

Owner:LANGHUO MEDICAL MATERIAL BEIJING

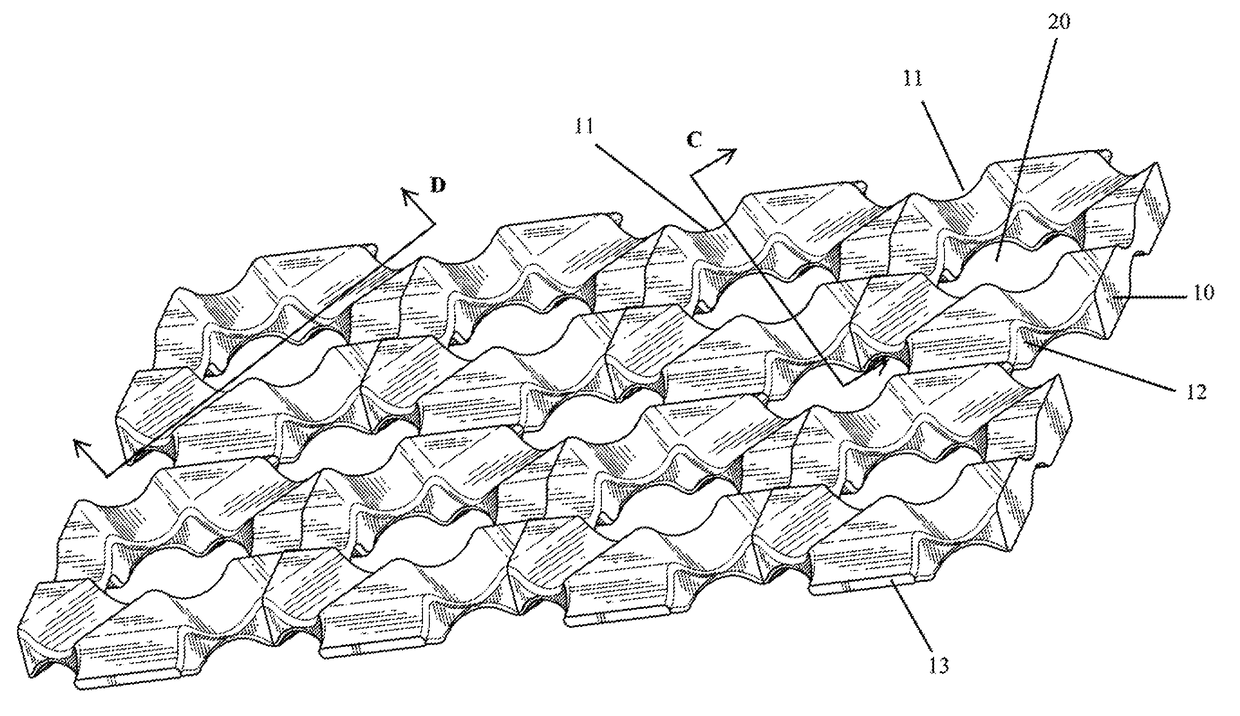

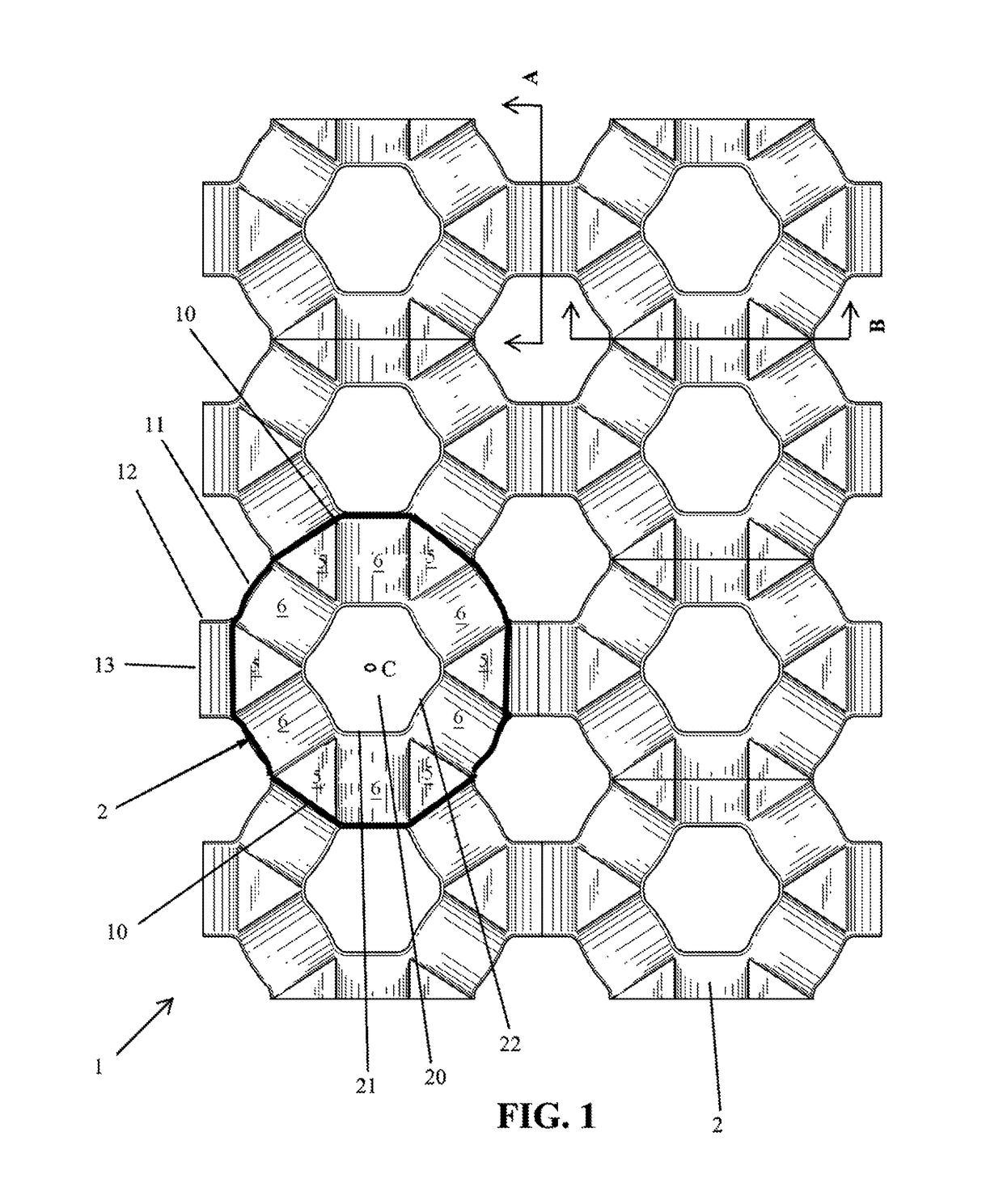

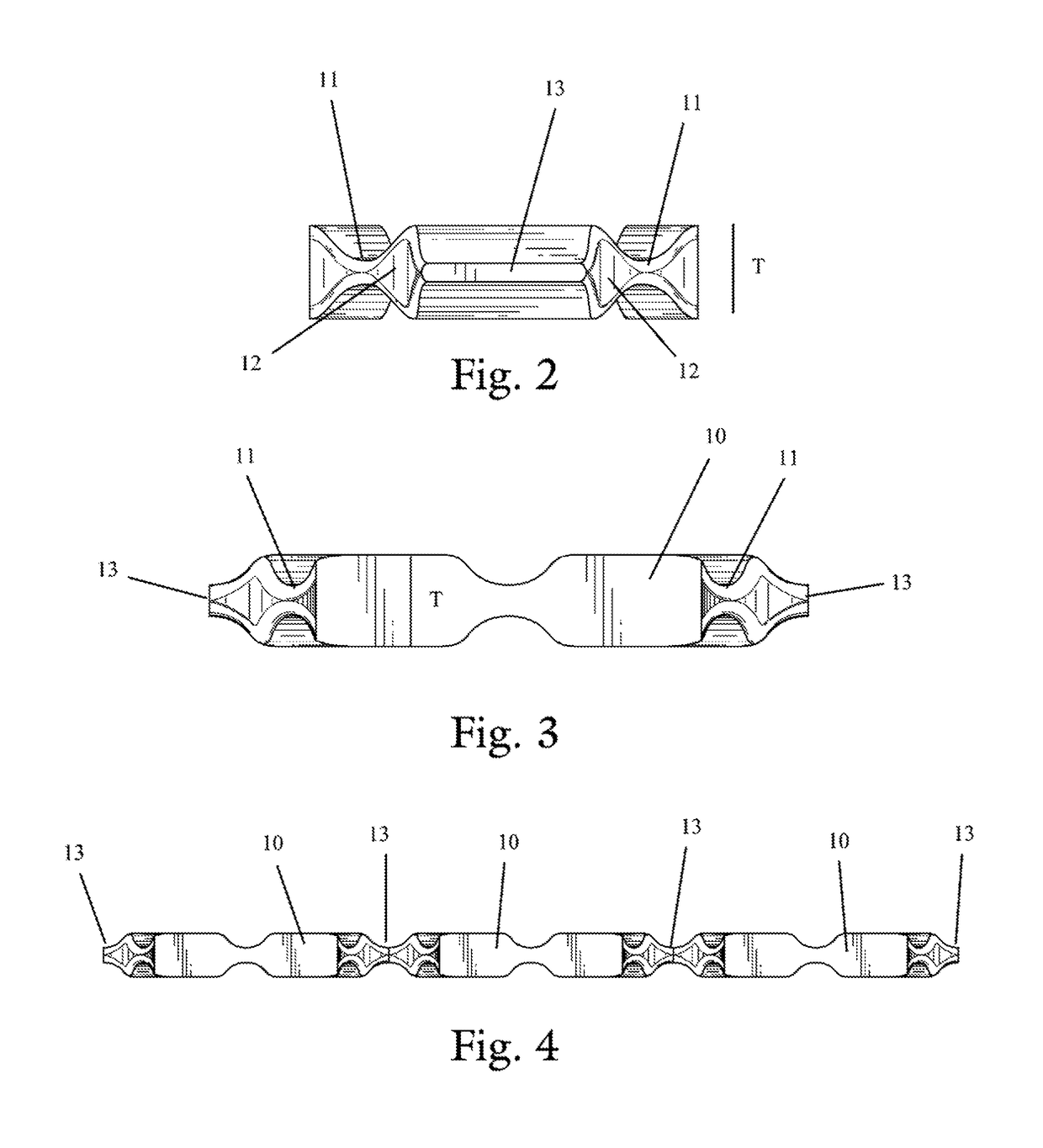

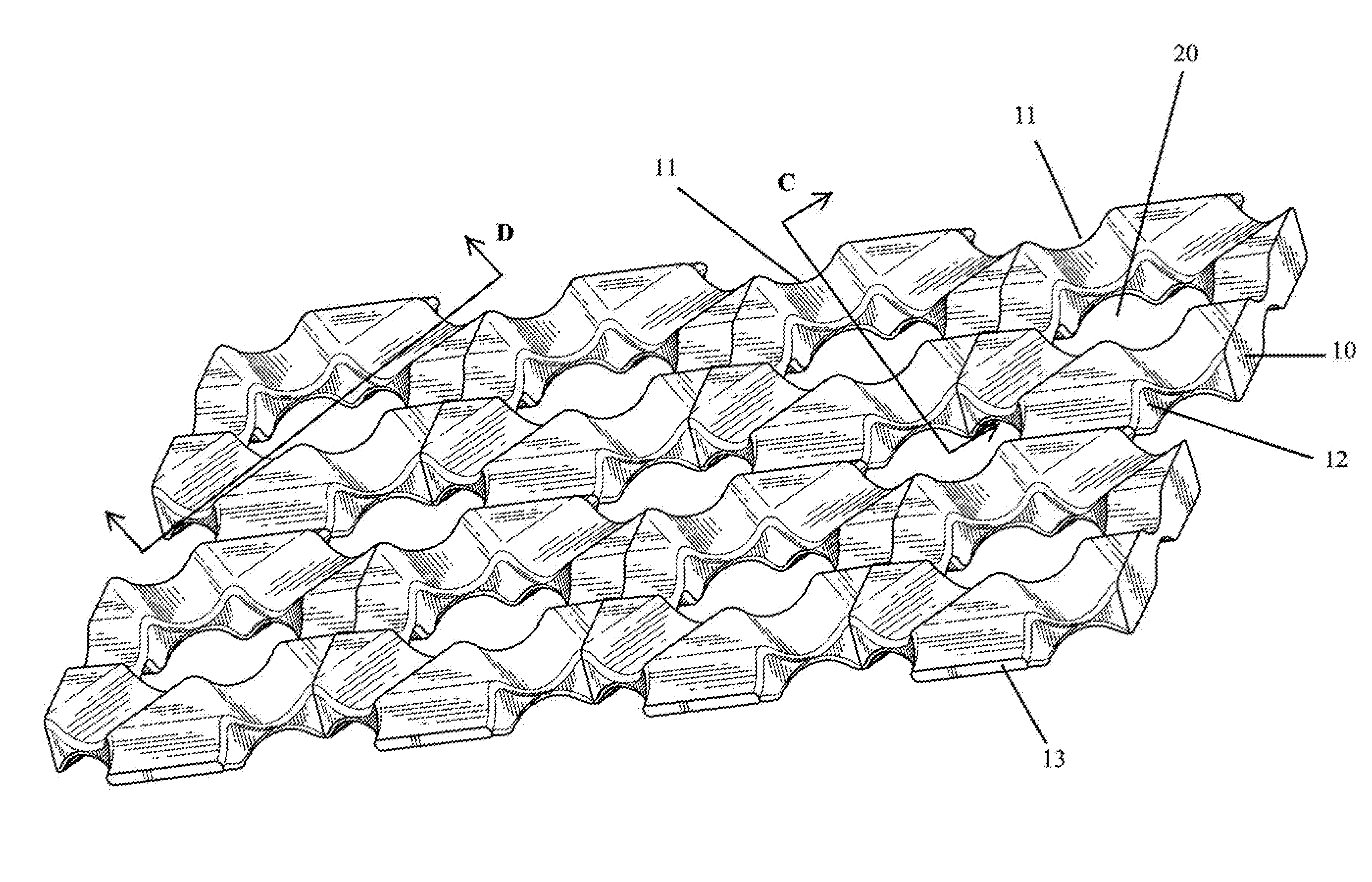

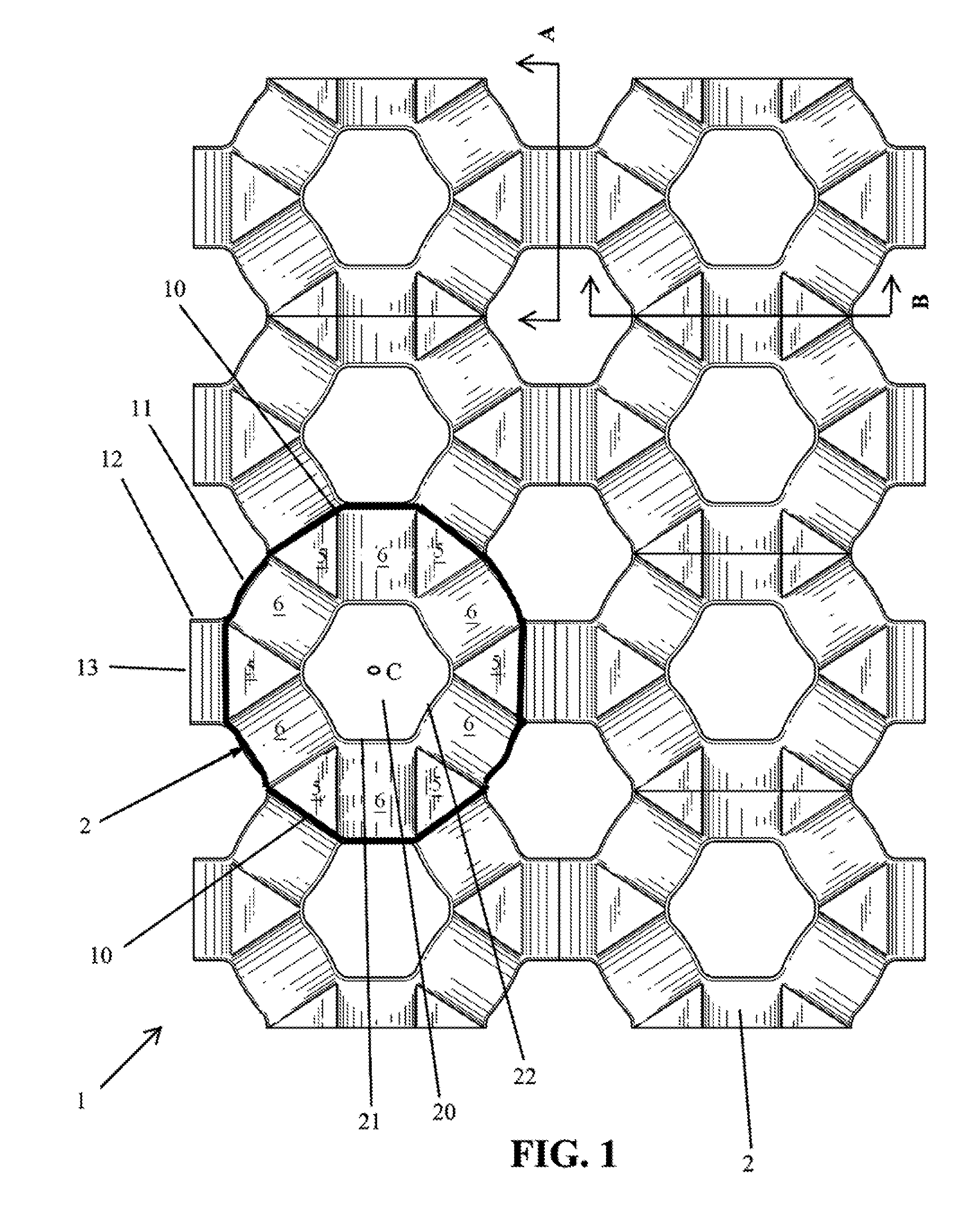

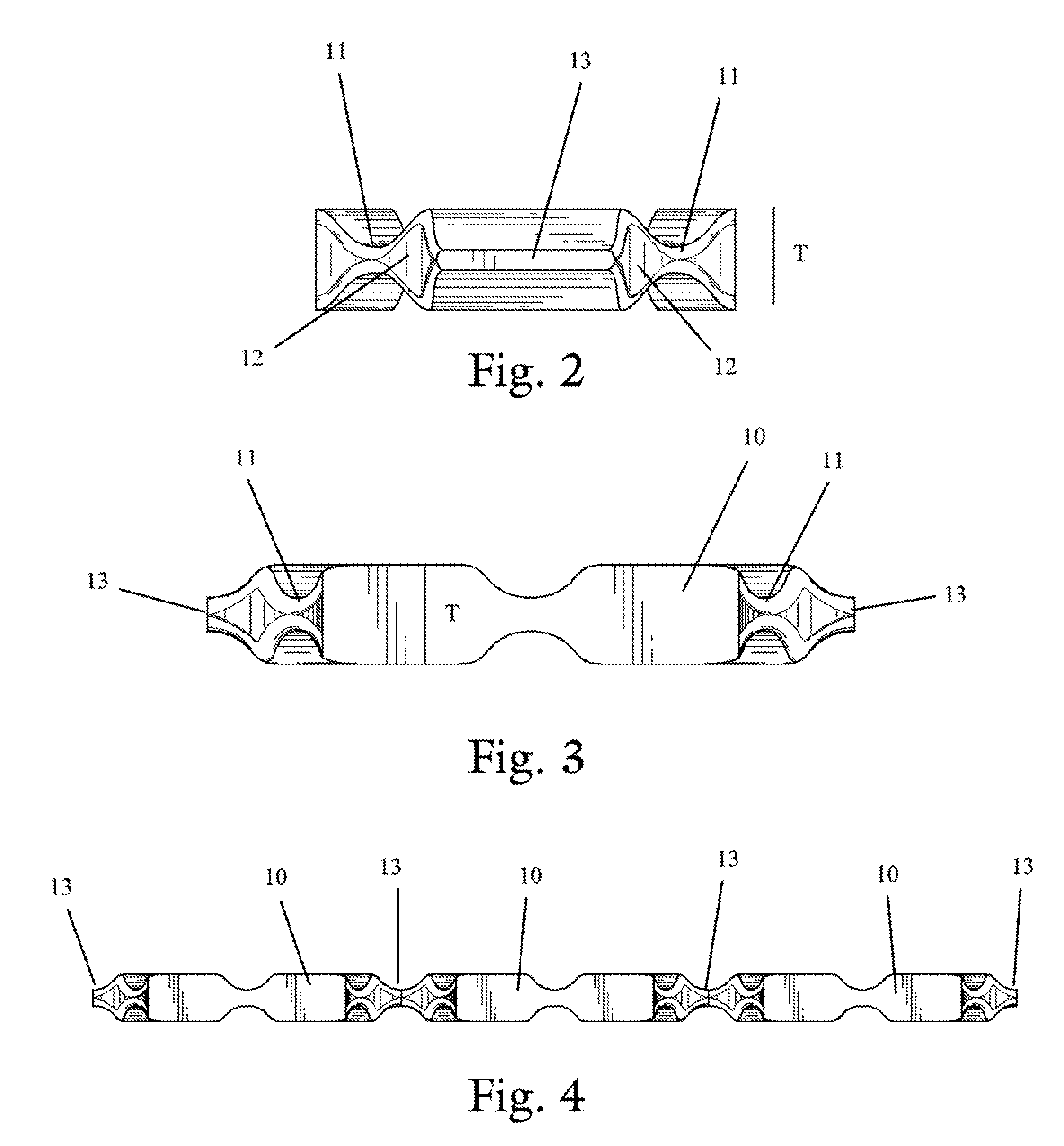

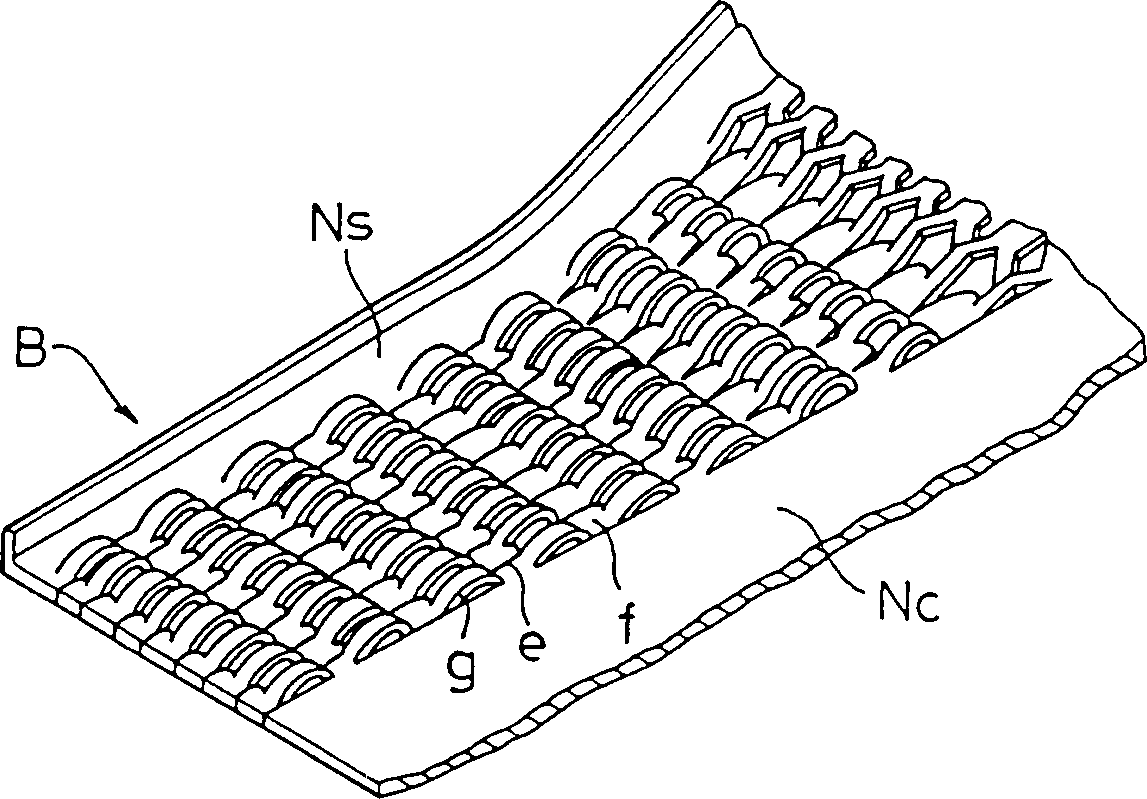

Protective padding layer

ActiveUS9907343B2Improve breathabilityImprove comfortBall sportsDomestic articlesEngineeringCompetitive sport

Owner:WM T BURNETT IP

Protective padding layer

ActiveUS20150335079A1Improve breathabilityImprove comfortLayered productsBall sportsEngineeringMechanical property

Owner:WM T BURNETT IP

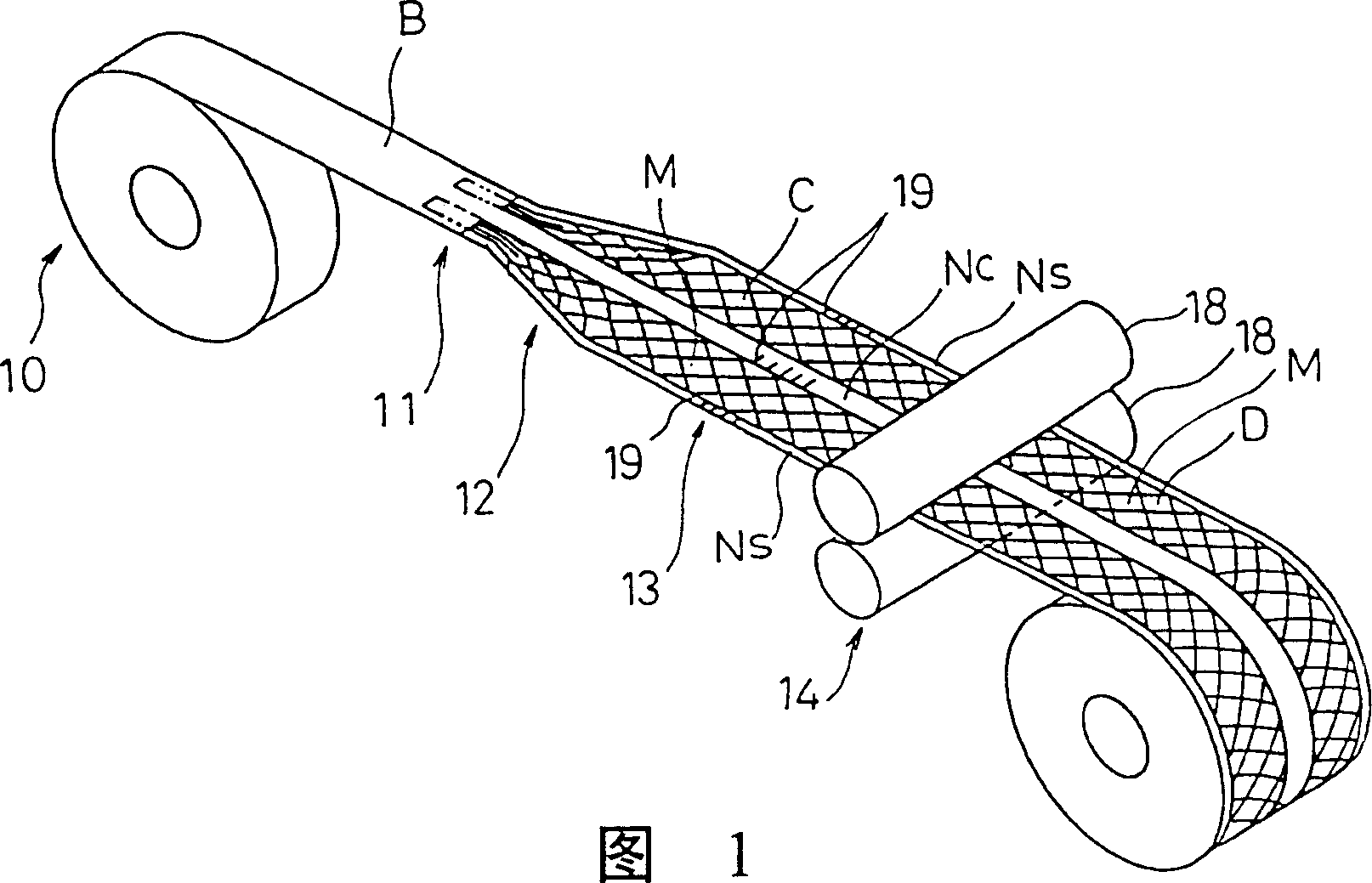

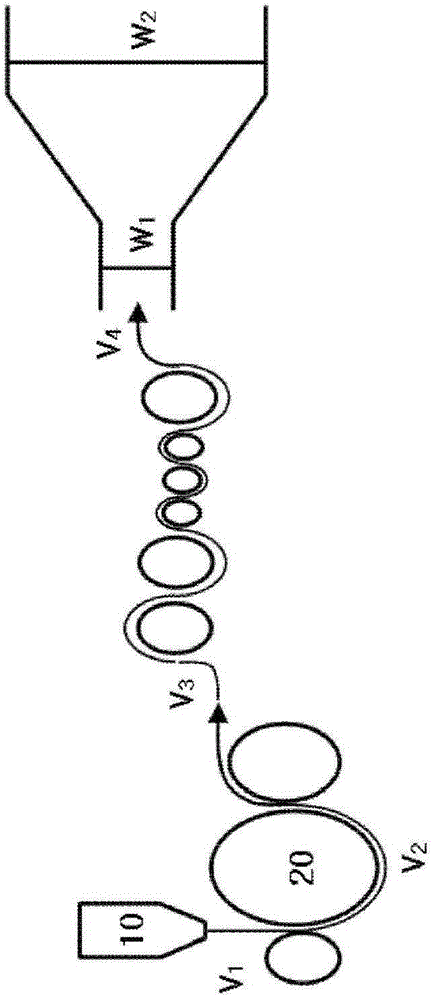

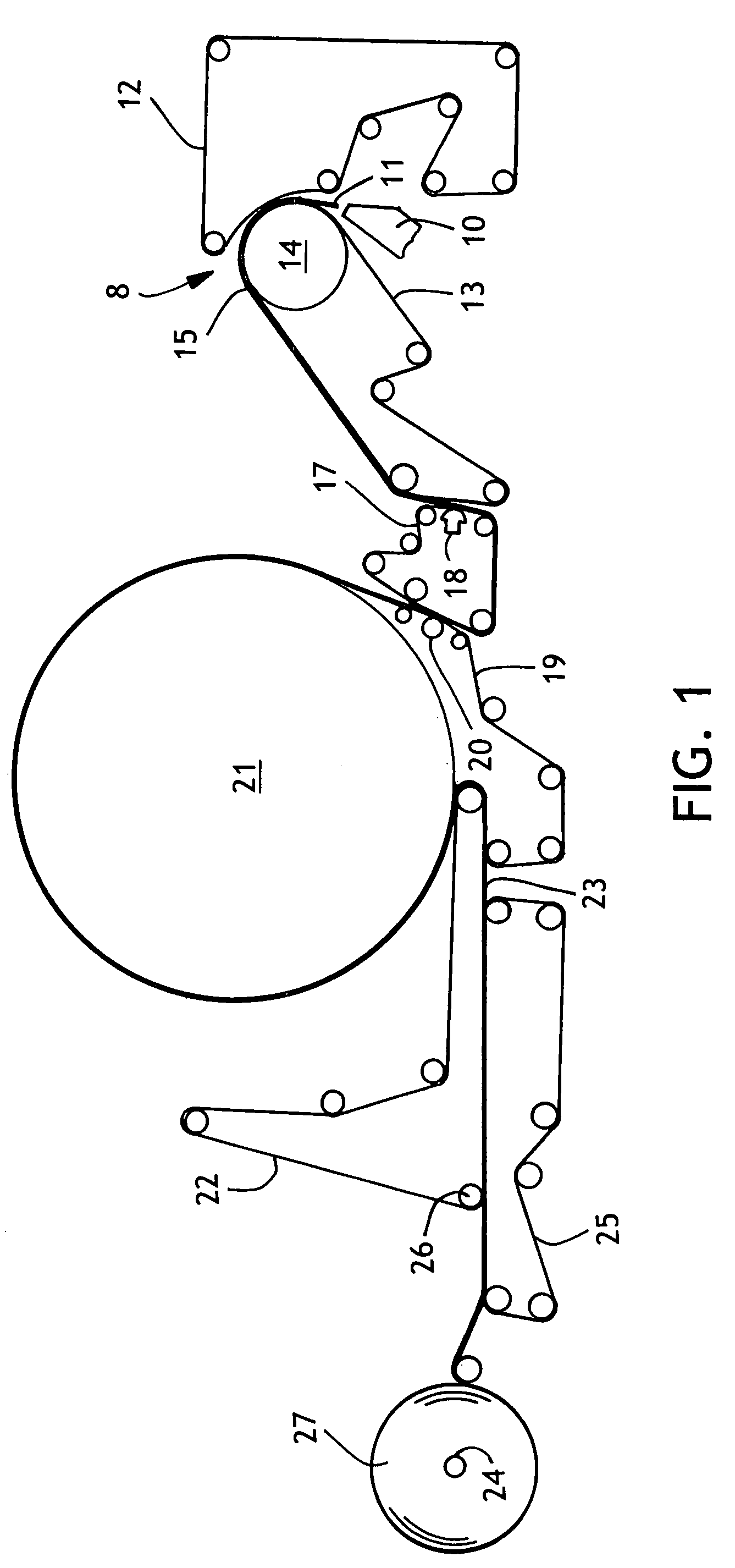

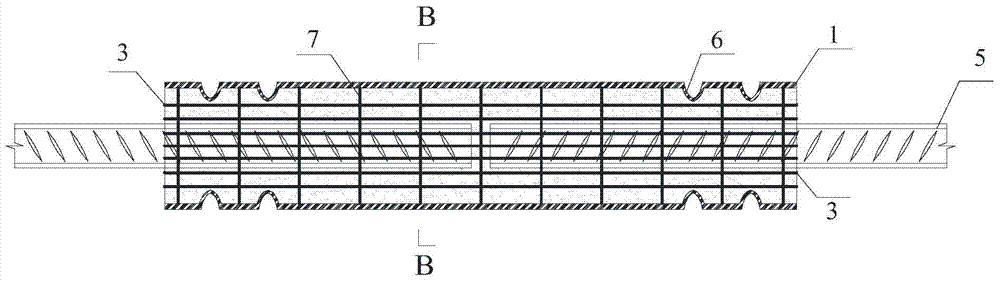

Method and device for making extension net slice and battery using the extension net slice

InactiveCN1156040CHigh strengthIncrease widthElectrode manufacturing processesFinal product manufactureEngineeringMechanical engineering

A method for manufacturing expanded mesh sheet is provided, including laminating a plurality of tabular cutter forming bladed part for joint-cutting in prescribed space to form upper die and lower die; delivering the metal strip piece into the space of the upper die and lower die; driving and reversing oppositely by driving the upper die and lower die; forming a plurality of slot crosslinkingly along the length direction of the strip piece; then expanding the strip piece to form mesh. The invention can effectively process mesh by reciprocating type and can process the reticular piece with slight mesh which is necessary for small-sized and powerful battery.

Owner:PANASONIC CORP

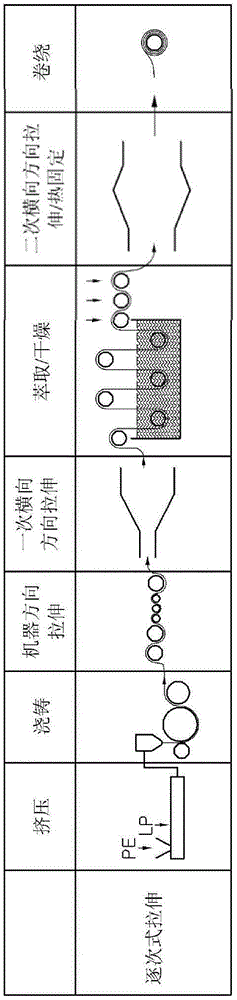

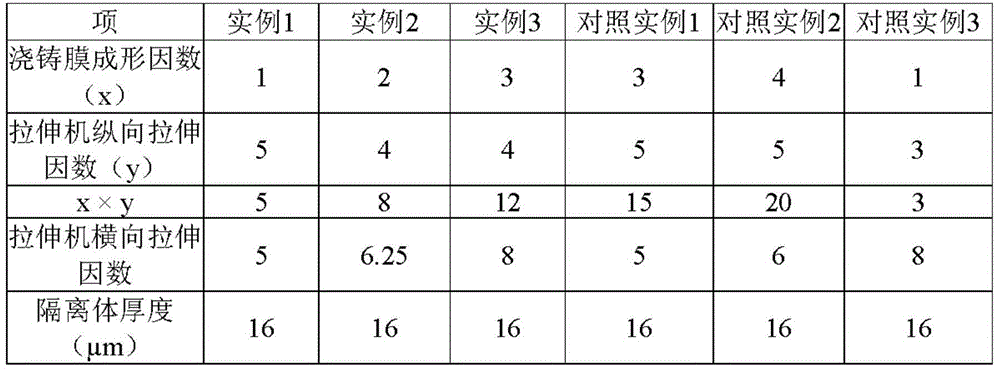

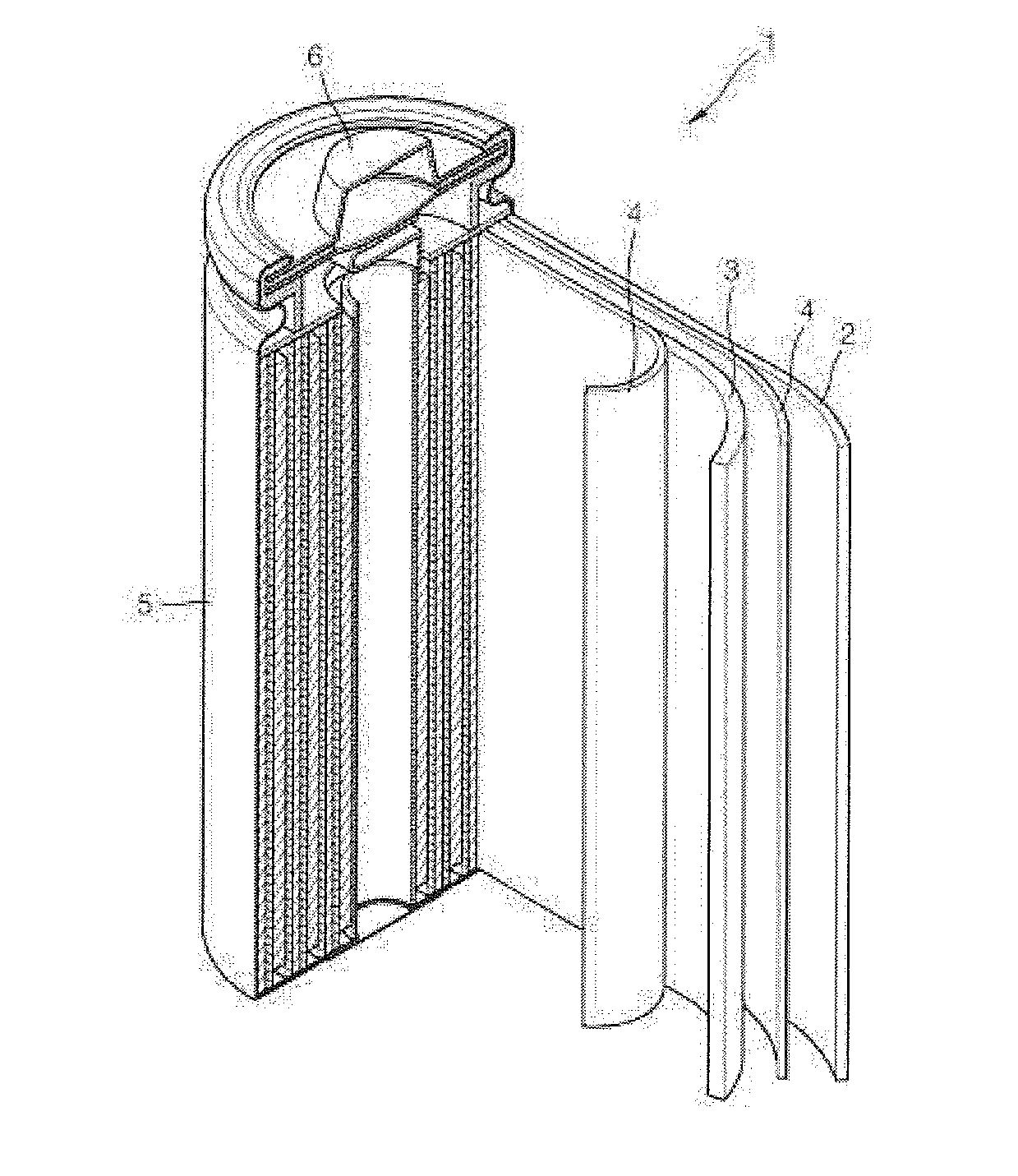

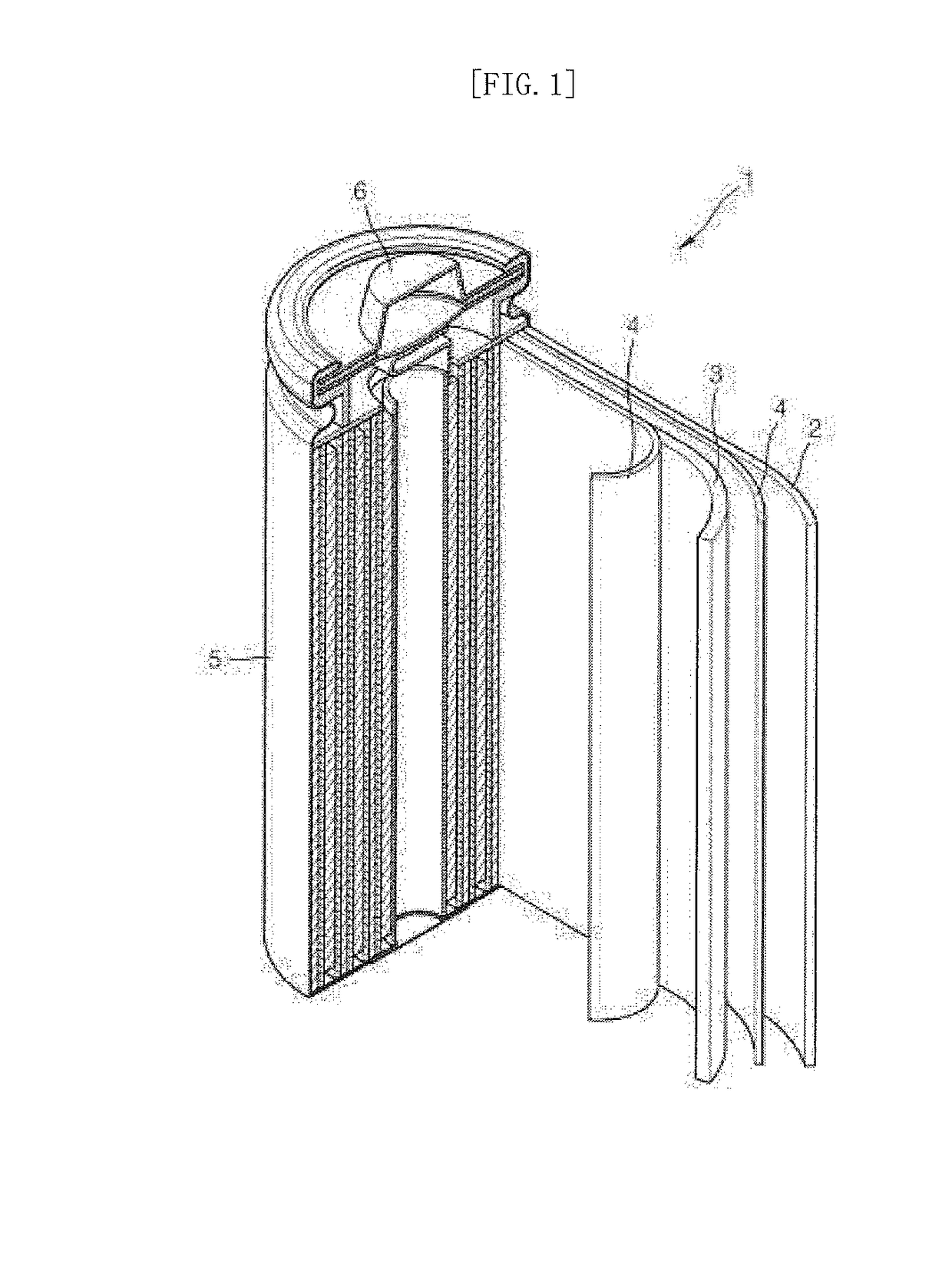

Method for producing separation membrane, and said separation membrane and battery using same

InactiveCN104871342AHigh tensile strengthHigh heat shrinkageCell seperators/membranes/diaphragms/spacersFinal product manufacturePolyolefinElectrical battery

The present invention relates to a method for producing a polyolefin-based porous separation membrane and, more particularly, to a method for producing a separation membrane having improved tensile strength and thermal shrinkage rate by adjusting the stretching factor of a base film during the casting and stretching processes of a separation membrane production process. Also, the present invention relates to a polyolefin-based porous separation membrane having a small difference in tensile strength between the longitudinal direction and the transverse direction of the separation membrane, excellent tensile strength, and improved thermal shrinkage rate and improved puncture strength. Further, the present invention relates to an electrochemical battery of which the dimensional stability under heat and tension is improved using the separation membrane.

Owner:SAMSUNG SDI CO LTD

Low-specific-resistance and high-plasticity silicon-manganese-nickel alloy wire and preparing method and application thereof

The invention discloses a low-specific-resistance and high-plasticity silicon-manganese-nickel alloy wire and a preparing method and application thereof, and belongs to the technical field of nonferrous metal alloy materials. The alloy wire comprises chemical components including, by weight percent, 1.9%-2.5% of Si, 0.2%-0.7% of Mn, 0.2%-0.7% of Ni, smaller than or equal to 0.4% of Zn, smaller than or equal to 0.2% of Sn and the balance Cu. The preparing process includes the first step of raw material preparing and burdening, the second step of vacuum smelting, the third step of cast ingot forging, the fourth step of hot rolling, the fifth step of cold machining and middle process vacuum annealing and the sixth step of stretching treatment and finished product annealing. The specific resistance of the manganese-nickel alloy wire is 0.15-0.15 micron omega.m, the tensile strength is larger than or equal to 260 N / mm<2>, and the ductility is larger than or equal to 25%. The low-specific-resistance and high-plasticity silicon-manganese-nickel alloy wire and the preparing method and application thereof can be used for electric light source fuses or electron components or heating wires.

Owner:沈阳新海合金新材料有限公司

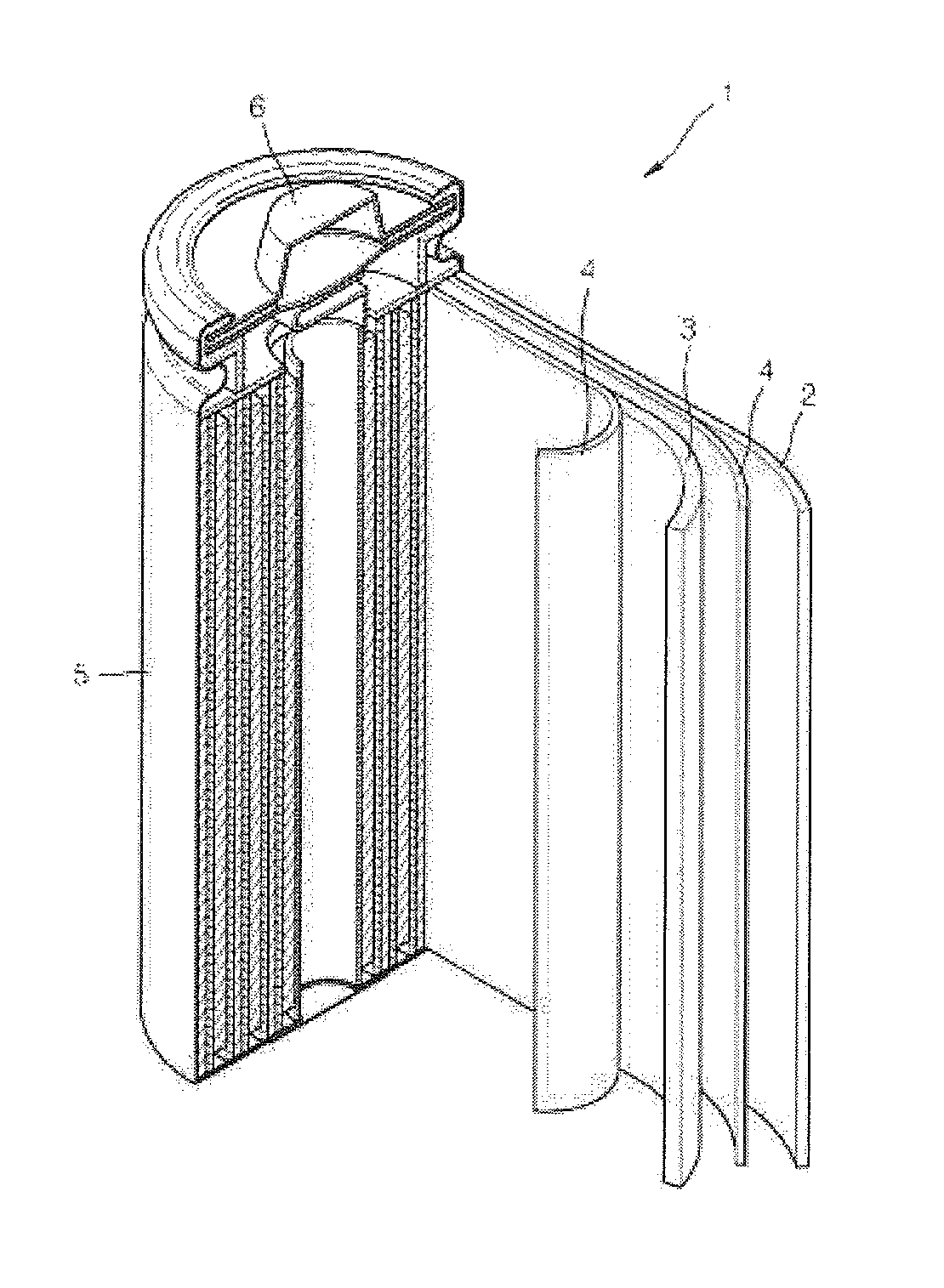

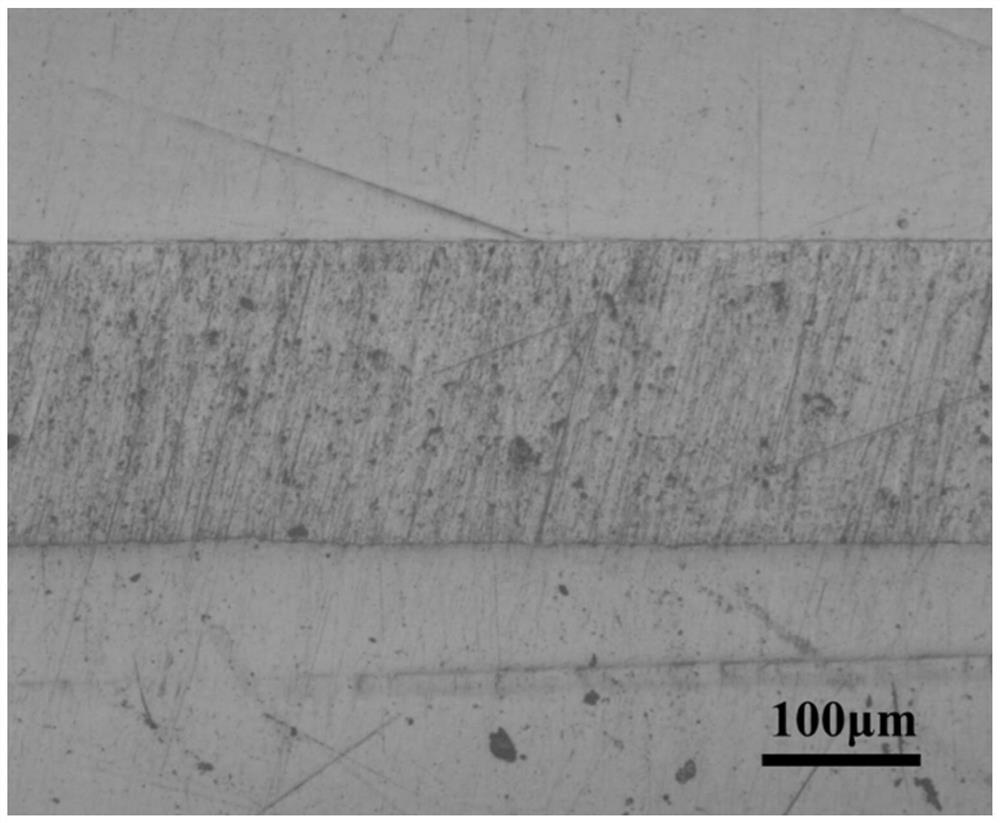

Electrolytic copper foil, and collector, negative electrode, and lithium battery comprising same

ActiveUS20170141404A1Increase mean diameterUniform tensile strengthElectrode carriers/collectorsNegative electrodesCrystalliteCopper foil

Disclosed is an electrolytic copper foil obtained by heat treating a copper foil manufactured through electrolysis, the electrolytic copper foil having specific resistivity of 1.68 to 1.72 μΩ·cm and a grain mean diameter of a crystallite of 1.0 to 1.5 μm.

Owner:ILJIN MATERIALS CO LTD

High-reinforced high-mechanical capacity rubber material

The invention discloses a high-reinforced high-mechanical capacity rubber material. The high-reinforced high-mechanical capacity rubber material comprises, by weight, 50 to 55 parts of butyl rubber, 25 to 32 parts of ethylene propylene diene monomer, 15 to 22 parts of polyacrylate rubber, 0.8 to 1.3 parts of tert-butyl cumyl peroxide, 0.5 to 1 part of 2-mercaptoimidazoline, 0.8 to 1.5 parts of silane coupling agent, 1 to 1.5 parts of N-Cyclohexyl-2-benzothiazolesulfenamide, 1 to 3 parts of nano-zinc oxide, 30 to 42 parts of montmorillonite, 30 to 40 parts of modified heavy calcium carbonate, 20 to 25 parts of ultrafine talcum powder, 15 to 22 parts of calcined clay, 1 to 2 parts of antioxidant 4020, 1 to 2 parts of antioxidant NBC, 1 to 2 parts of trioctyl trimellitate, and 0.5 to 1 part of dioctyl phthalate. The high-reinforced high-mechanical capacity rubber material is excellent in mechanical properties, excellent in reinforcing properties, and excellent in material compatibility.

Owner:合肥市再德高分子材料有限公司

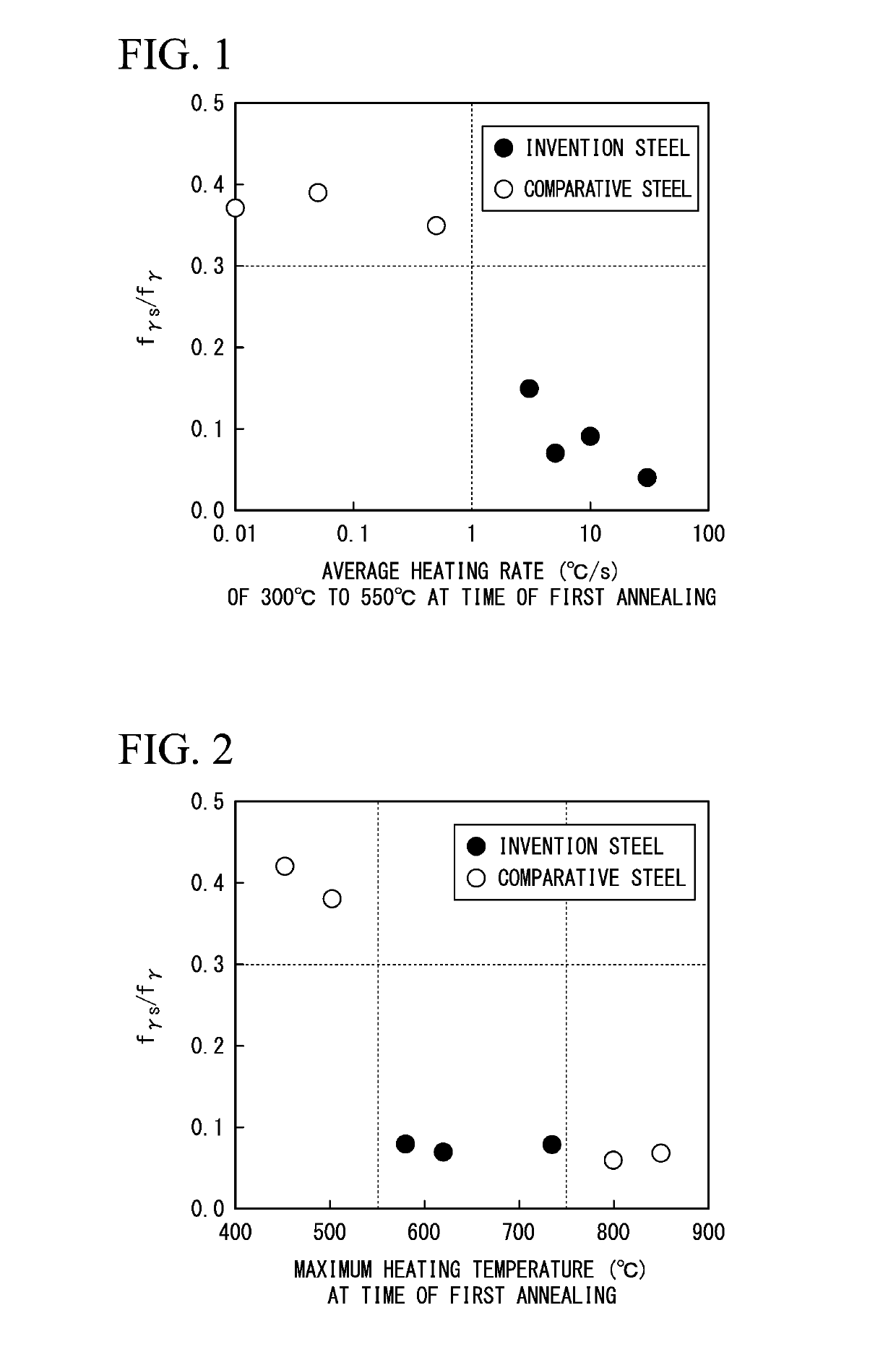

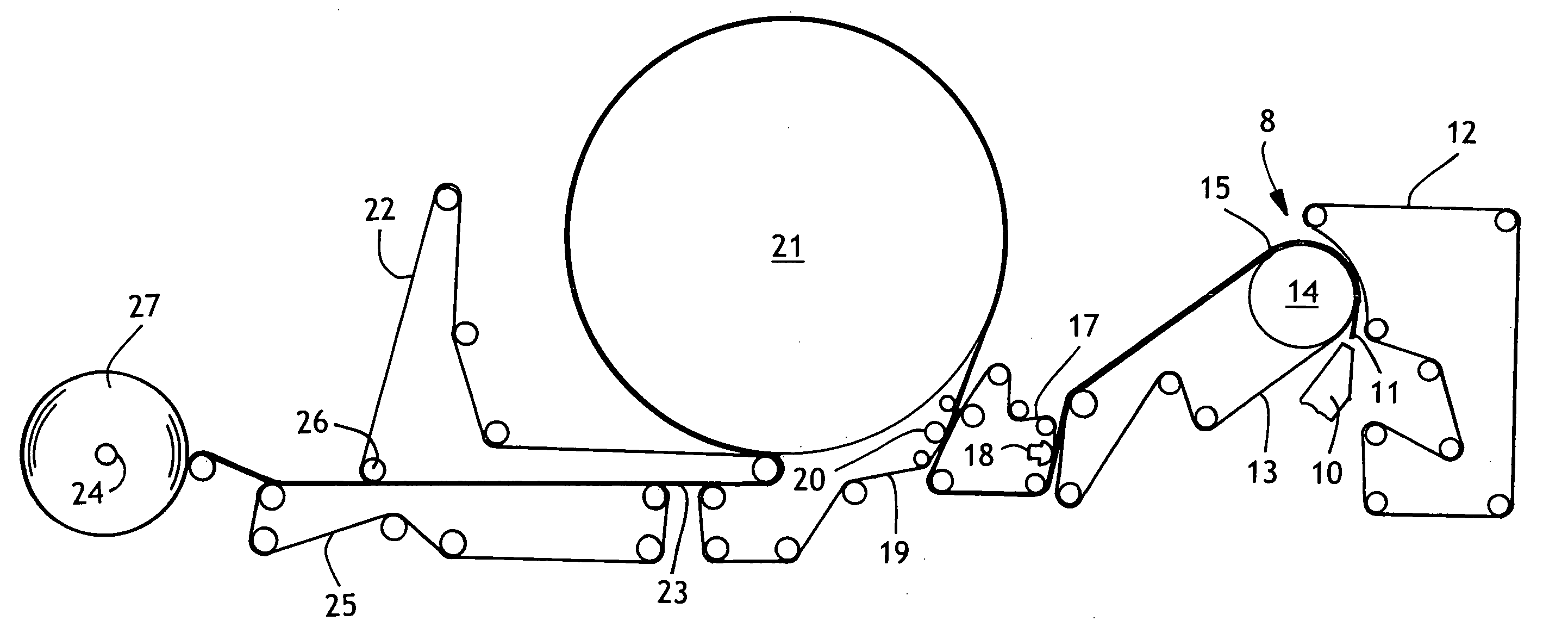

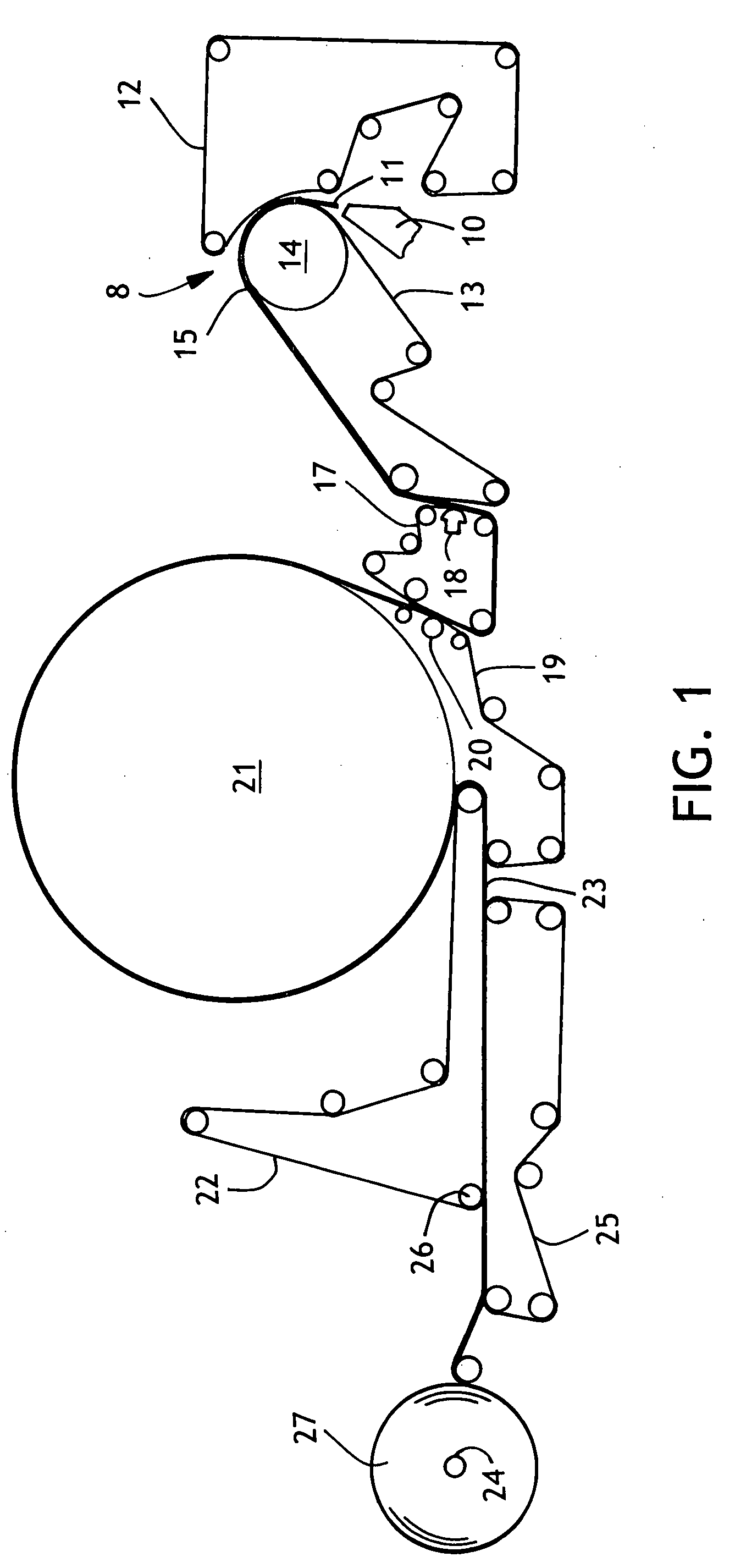

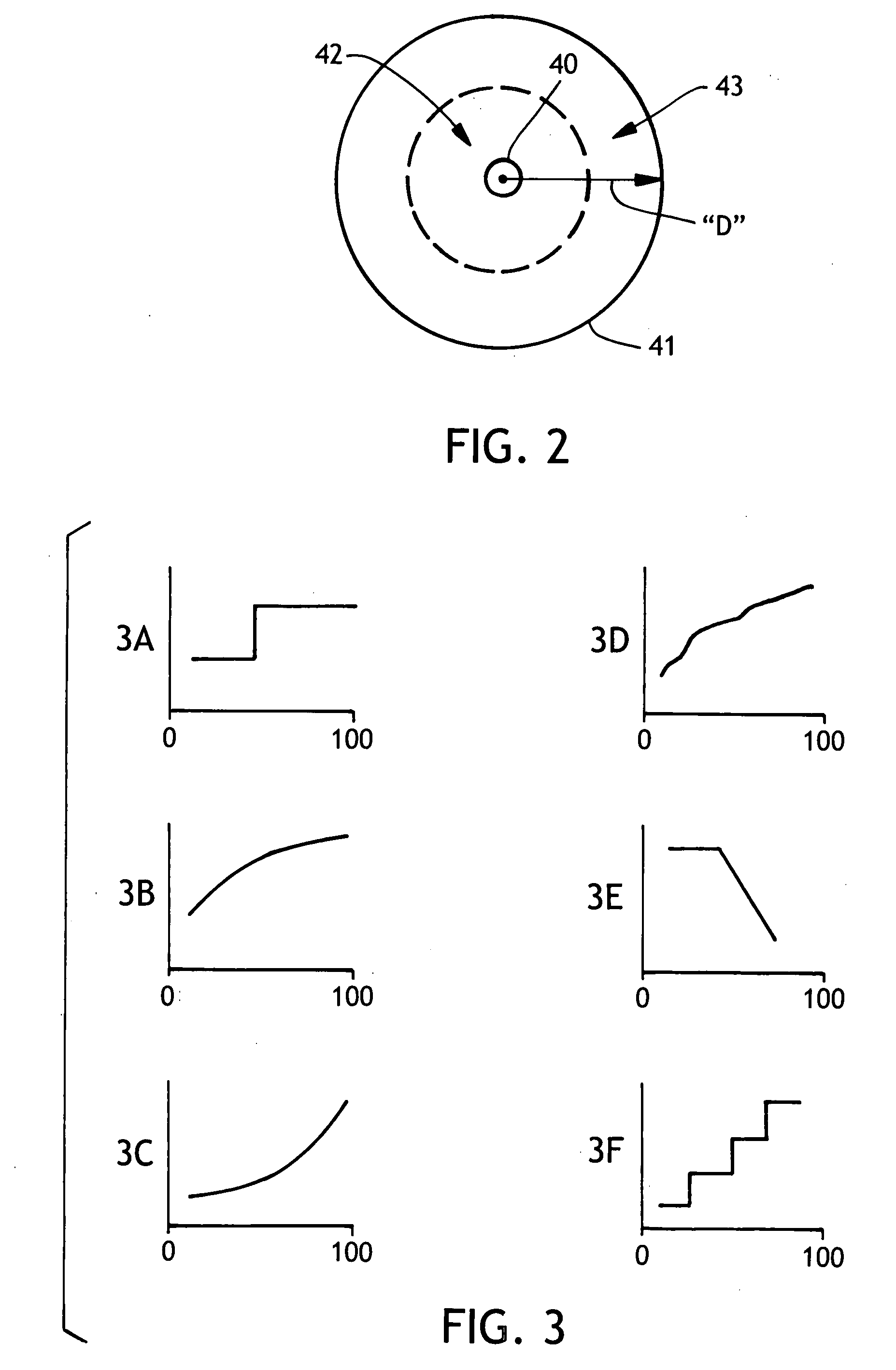

Tissue machine parent roll having variable intrinsic sheet dryness

ActiveUS8277609B2Reduce moisture contentIncreased moisture content reduces the ability of a tissue sheet to resist compressionNon-fibrous pulp additionNatural cellulose pulp/paperMoistureBiomedical engineering

The intrinsic tissue sheet properties of tissue sheets wound into a parent roll during manufacturing can be purposely varied in order to provide a z-directional gradient within the parent roll. For example, the moisture content of the tissue sheet can be made lower in the core region of the parent roll and greater in the outer region of the parent roll. Such gradients can ultimately provide more uniformity of the intrinsic property within the final tissue product.

Owner:KIMBERLY-CLARK WORLDWIDE INC

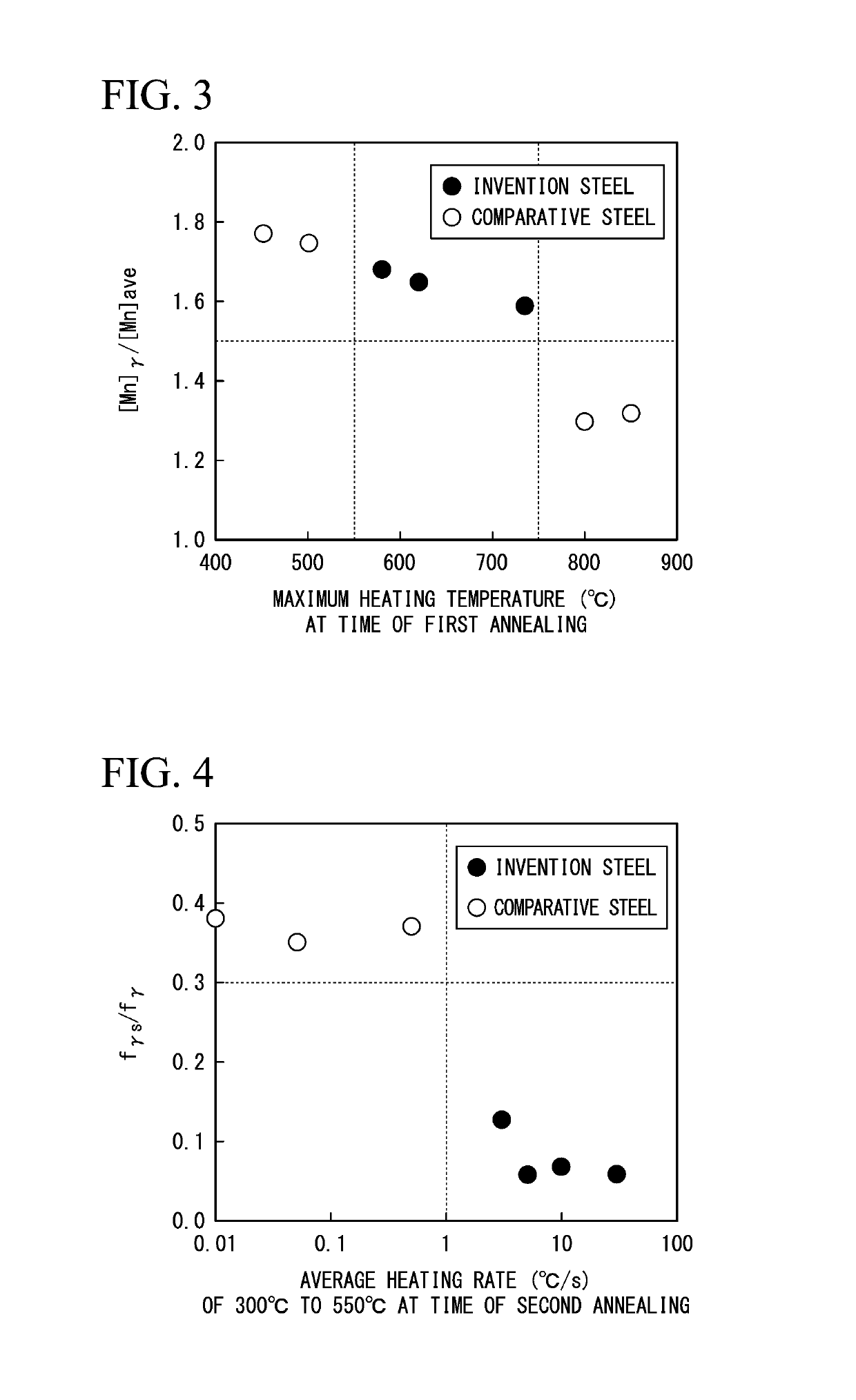

Steel sheet

InactiveUS20190211427A1Improve solderabilityTensile strength highHot-dipping/immersion processesFurnace typesChemical compositionSheet steel

A steel sheet according to an aspect of the present invention includes a predetermined chemical composition; in which a metallographic structure in a ¼ t portion contains residual austenite of 4 volume % to 70 volume %; [Mn]γ / [Mn]ave>1.5 is satisfied in the ¼ t portion; fγs / fγ≤0.30 and [C]×[Mn]≥0.15 are satisfied in the ¼ t portion.

Owner:NIPPON STEEL CORP

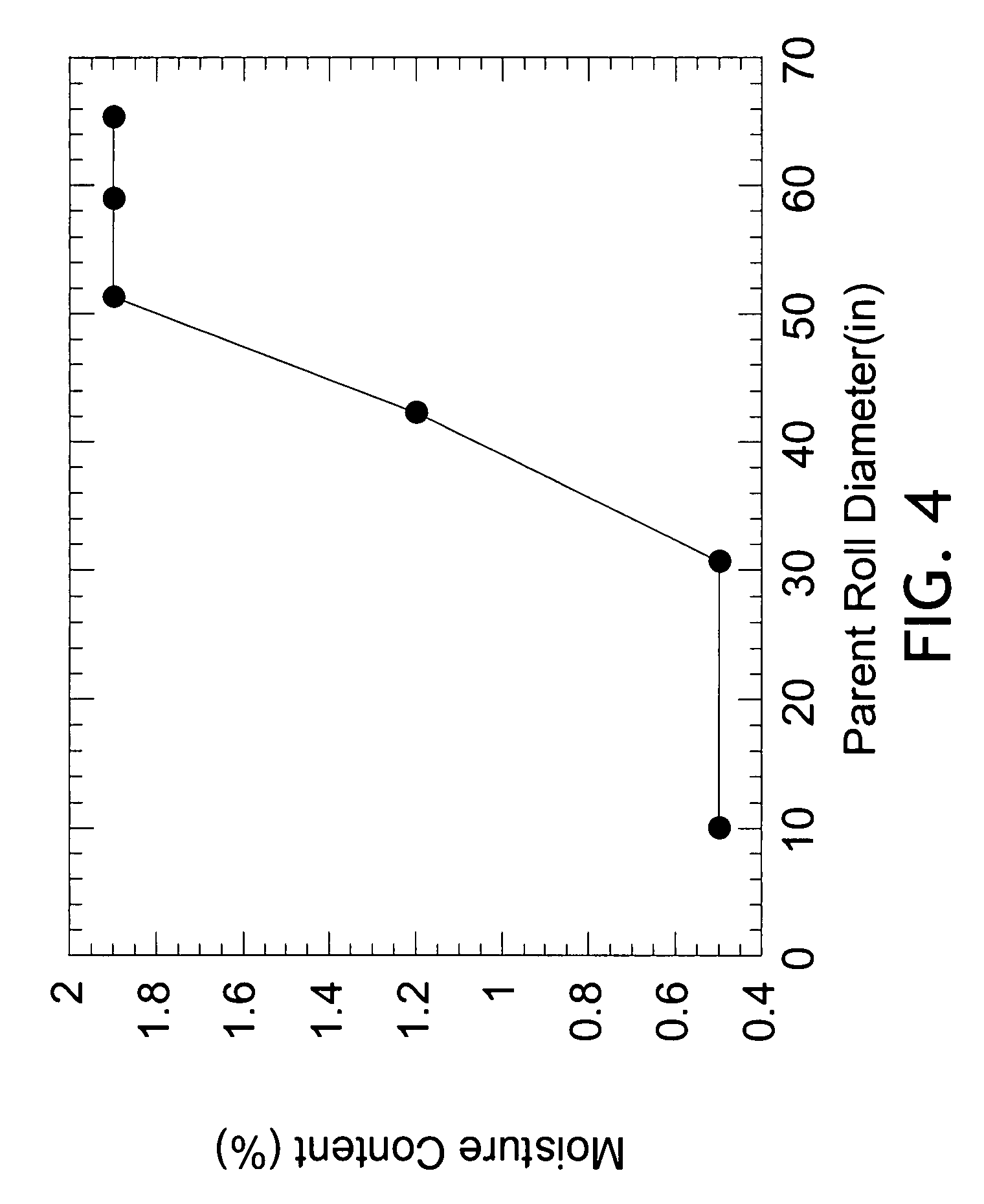

Tissue machine parent roll with a Z-direction intensive property profile

ActiveUS20090056894A1Reduce moisture contentIncreased moisture content reduces the ability of a tissue sheet to resist compressionNon-fibrous pulp additionNatural cellulose pulp/paperMoistureBiomedical engineering

The intrinsic tissue sheet properties of tissue sheets wound into a parent roll during manufacturing can be purposely varied in order to provide a z-directional gradient within the parent roll. For example, the moisture content of the tissue sheet can be made lower in the core region of the parent roll and greater in the outer region of the parent roll. Such gradients can ultimately provide more uniformity of the intrinsic property within the final tissue product.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Coating composition for separator of lithium ion secondary battery and method for producing the separator

ActiveCN102942831BHigh temperature resistantLow densitySecondary cellsCell component detailsLithiumCoated surface

A coating composition for a lithium ion secondary battery separator and a method for manufacturing the separator. The coating composition comprises a heat-resistant resin and inorganic non-conducting insulating particles, wherein the heat-resistant resin comprises the molecular chains of oleophylic structural units, hydrophilic structural units and functional group structural units, and has a thermal decomposition temperature of higher than 250°C. The inorganic non-conducting insulating particles feature high temperature resistance, low density, low rigidity and low water absorption and so on. The composite micro-porous separator prepared by the coating composition features not only a low hole closing temperature and a high separator breaking temperature, but also a low thermal shrinkage rate, high bonding force between a heat-resistant coating and a substrate, good wettability of the heat-resistant coating surface and so on; and when used as a separator of a lithium ion secondary battery, the separator has good comprehensive properties and reliable safety performance.

Owner:河南惠强新能源材料科技股份有限公司

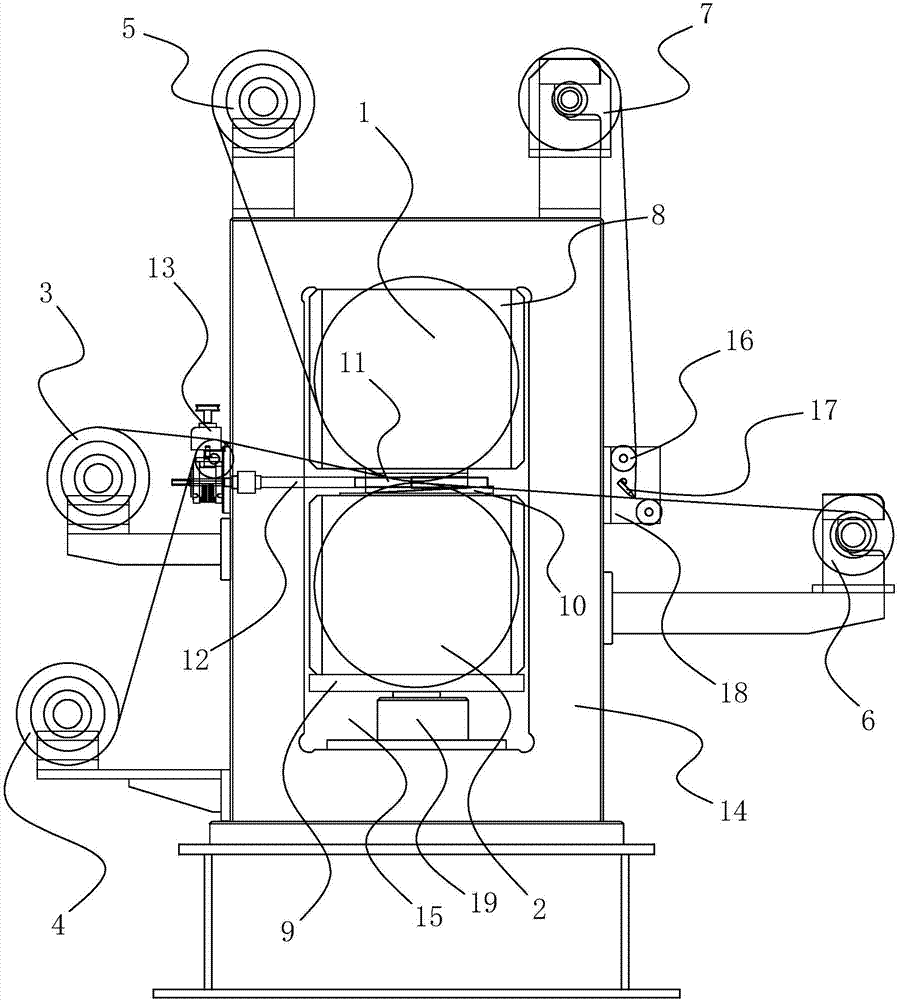

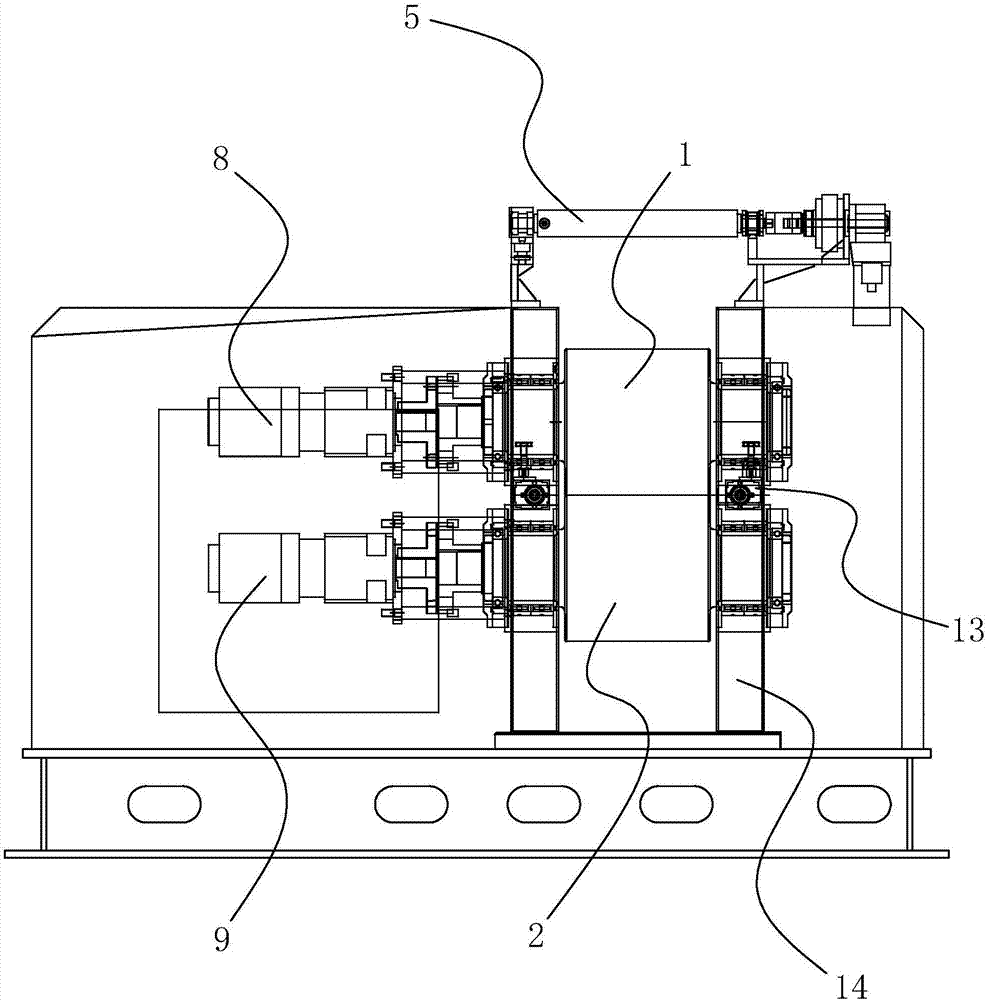

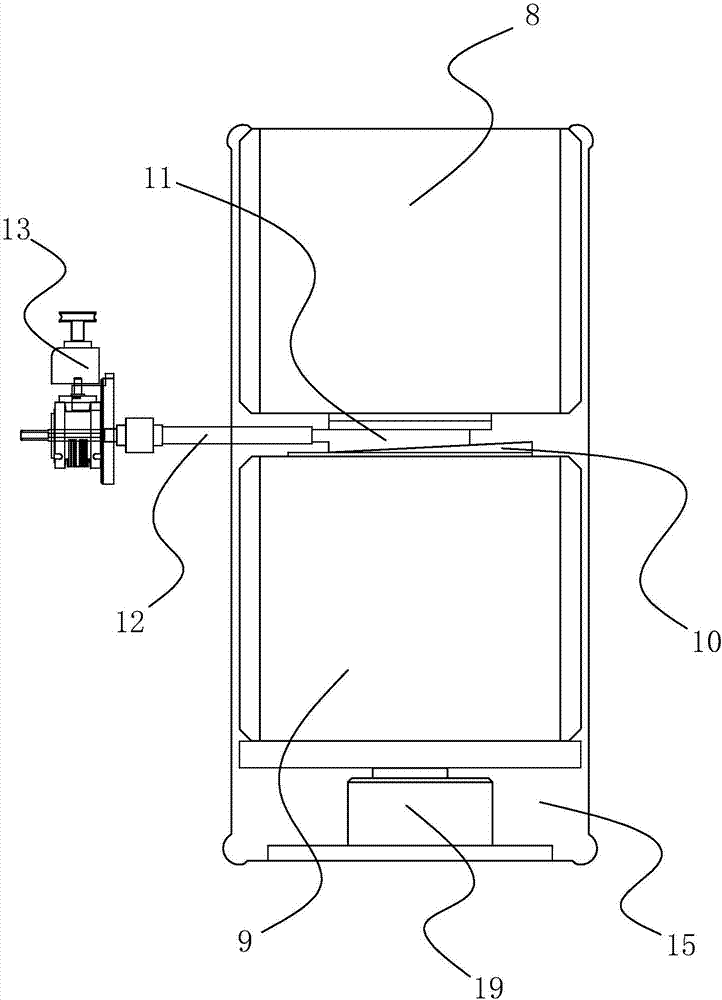

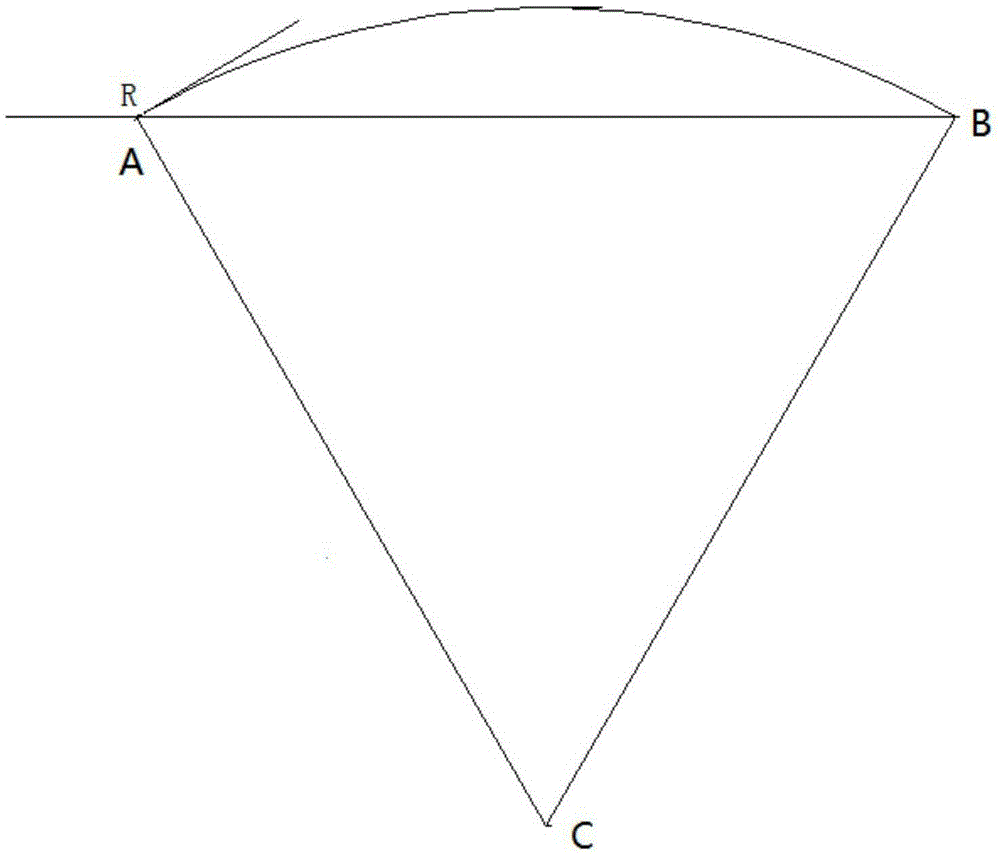

Gap-adjustable automatic calendering device for graphite heat-dissipation film

PendingCN107498975AQuality improvementGuaranteed to be smooth and cleanLamination ancillary operationsLaminationComposite filmGraphite

The invention discloses a gap-adjustable automatic calendering device for a graphite heat-dissipation film. The device comprises a base, an upper press roller, a lower press roller, a first unwinding roller, a second unwinding roller, a third unwinding roller, a first winding roller and a second winding roller, wherein the upper press roller and the lower press roller are arranged on the base; a gap between the upper press roller and the lower press roller is adjusted by a position adjusting assembly; a stripping mechanism is arranged at the front end of the second winding roller. According to the calendering device, smooth and clean surfaces of the press rollers are guaranteed, raw materials are saved, equipment can operate stably for a long time, and product quality is improved; production flexibility of the equipment is improved, and the relative position of the upper press roller and the lower press roller can be adjusted in time to meet the required calendering standard; the stripping position is adjusted by the stripping mechanism according to speed difference of the first winding roller and the second winding roller, so that an assisting film and a composite film can be conveyed under better tensile force, quality of the graphite heat-dissipation film is better, and overall tensile strength and color distribution are more uniform.

Owner:珠海市光环自动化科技有限公司

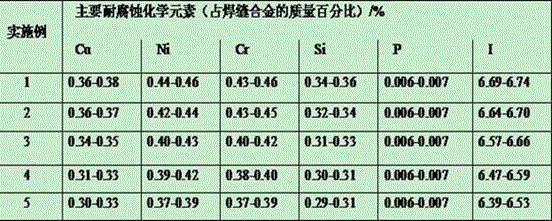

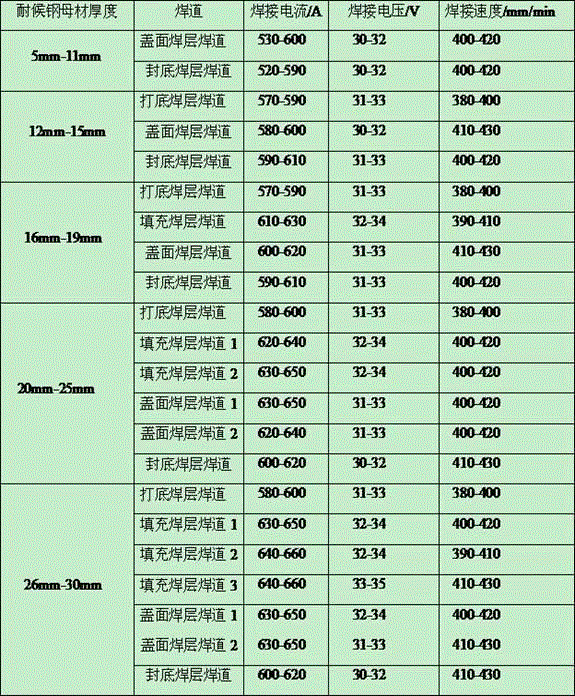

Weathering resistant steel welding line alloy and SAW welding method of weathering resistant steel

ActiveCN105296875AUniform tensile strengthBalanced Impact ToughnessArc welding apparatusCorrosion resistant alloyMaterials science

The invention belongs to the technical field of welding, and relates to weathering resistant steel welding line alloy and an SAW welding method of weathering resistant steel to obtain weathering resistant steel welding products capable of meeting the using requirement under the severe condition. The weathering resistant steel welding line alloy contains multiple abrasion resisting alloy elements, and therefore the using requirement under the severe condition can be met.

Owner:ZHEJIANG SHENGDA STEEL TOWER

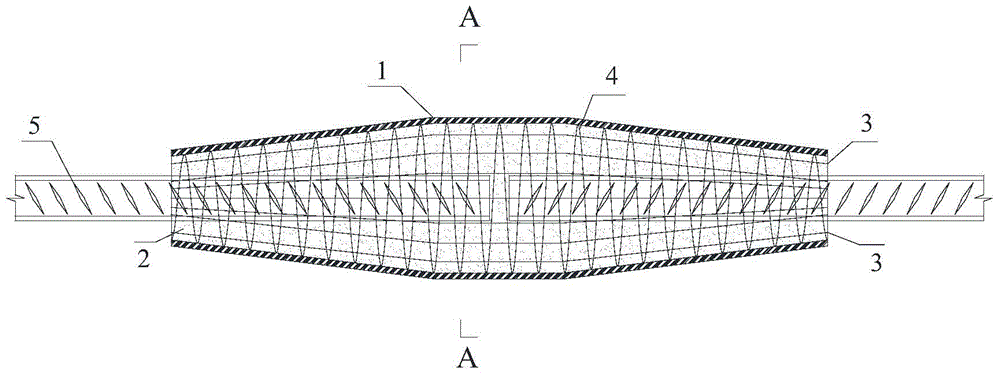

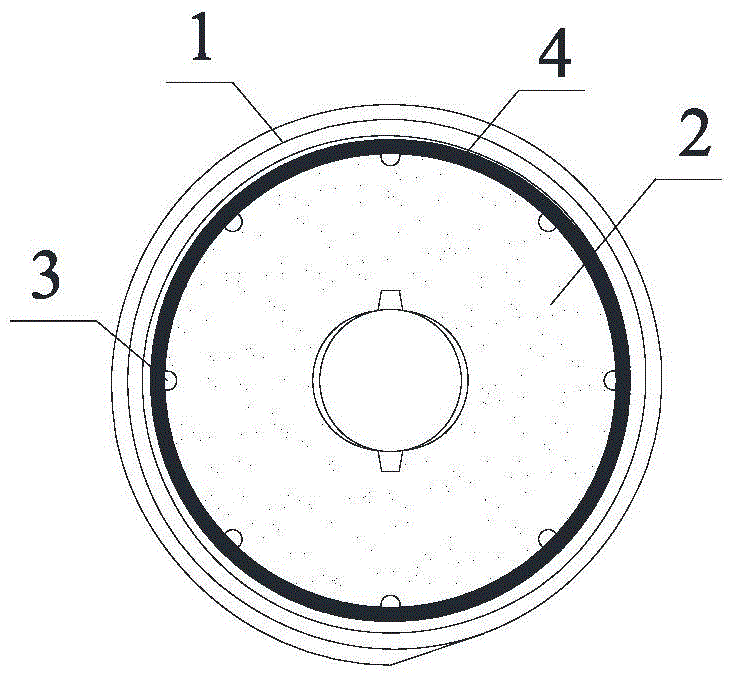

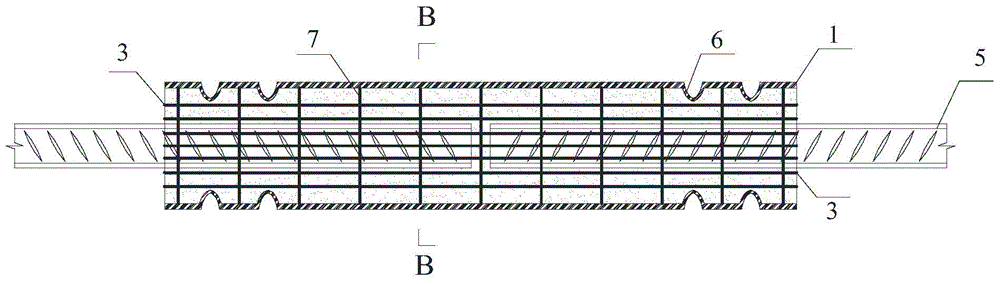

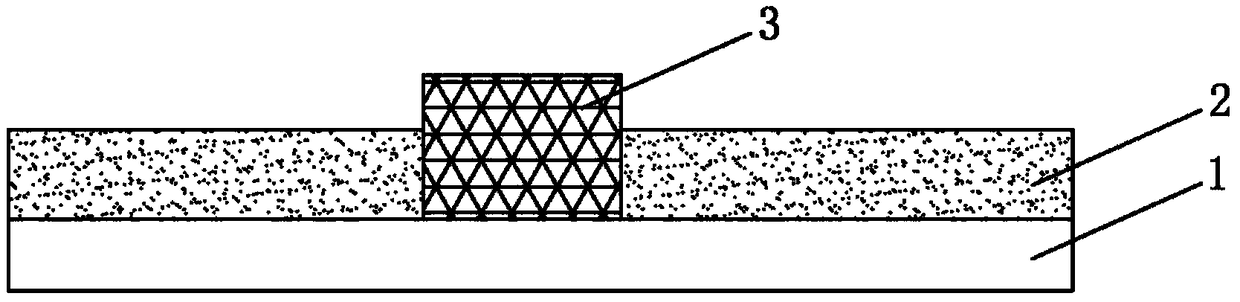

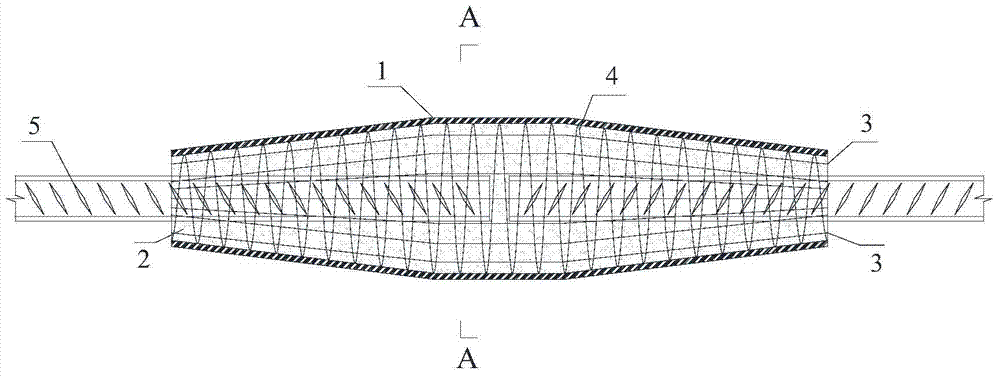

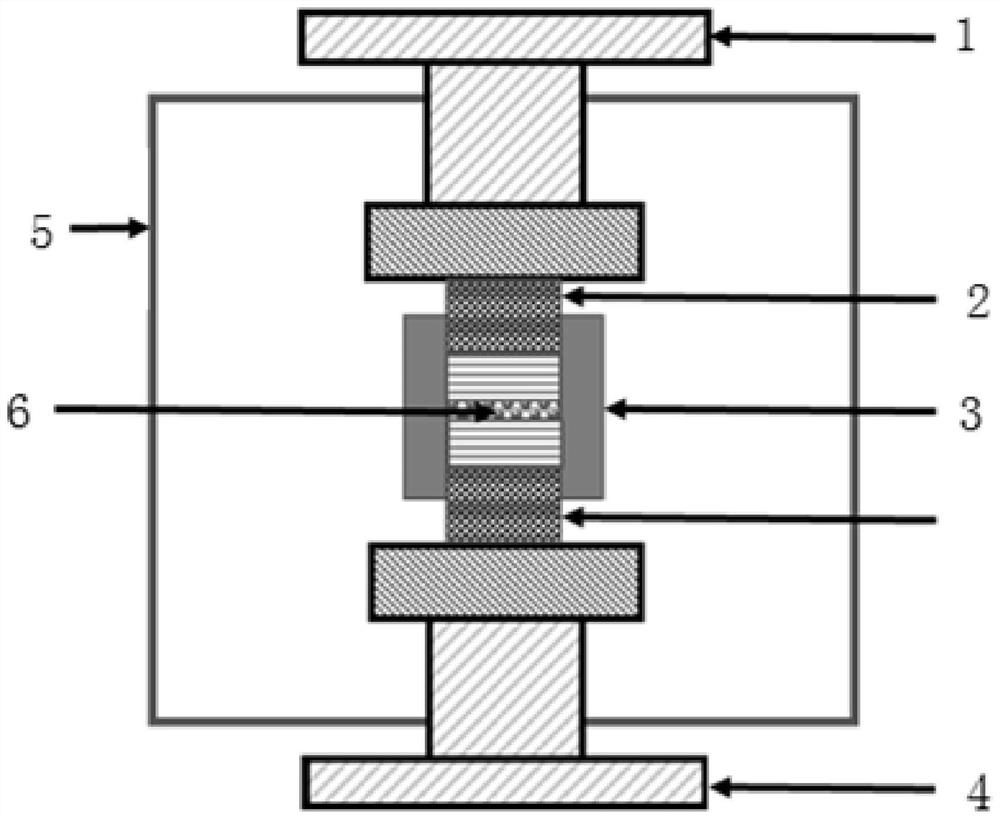

Coiled material steel bar grouting connector

ActiveCN105064618AReduce lateral stiffnessHigh tensile strengthBuilding reinforcementsRebarMechanical property

The invention discloses a coiled material steel bar grouting connector, and belongs to the field of a preassembled building structure in the civil engineering. The coiled material steel bar grouting connector comprises a coiled material, expansive mortar and a support frame, wherein the coiled material is a soft coiled building material; the support frame is provided with transverse and / or longitudinal stress bars; the expansive mortar is connected with steel bars; the coiled material is wound around the outer surface of the support frame; and the expansive mortar is injected into the coiled material. The coiled material steel bar grouting connector can be used for connecting steel bars between assembled components. The coiled material steel bar grouting connector can be arranged at a connecting joint part of the assembled components in the engineering, can bear the axial tension generated by building components under the load effect, and can enable the building material at the joint part to be subjected to coordinate deformation. The coiled material steel bar grouting connector has the advantages that the structural form is simple and free; the mechanical property is reliable; the installation is convenient and fast; the industrialization can be realized; and the coiled material steel bar grouting connector has wide engineering application prospects.

Owner:BEIJING UNIV OF TECH

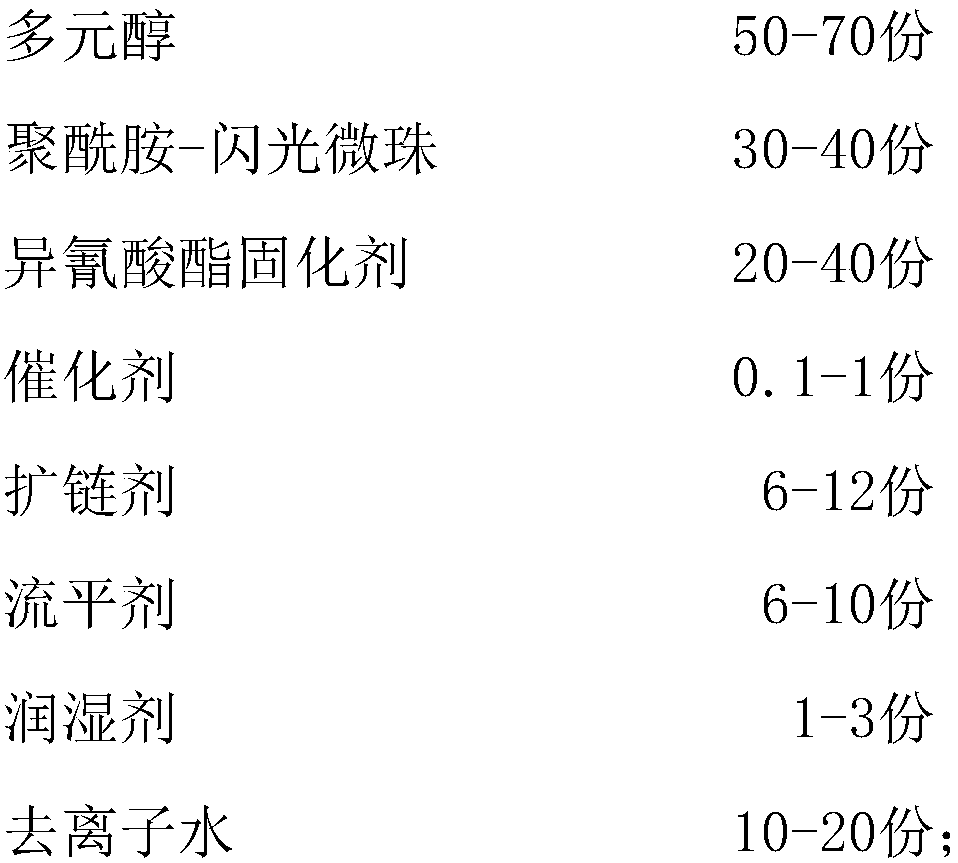

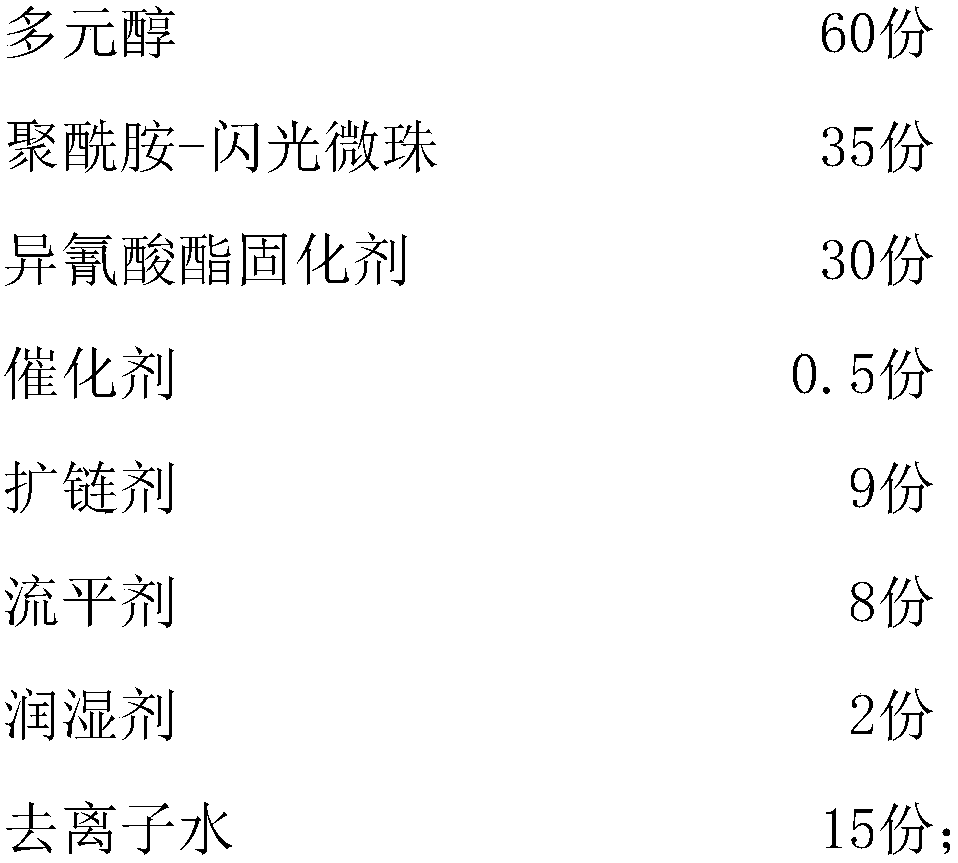

Shining waterproof zipper

ActiveCN109056361ALow impact of flash effectImprove suspension stabilitySlide fastenersTextiles and paperMicrospherePolyamide

The invention relates to the technical field of zippers, in particular to a shining waterproof zipper. The shining waterproof zipper comprises a cloth strap and a plurality of zipper teeth arranged onthe cloth strap, wherein a shining waterproof coating is compounded on the cloth strap, the shining waterproof coating is prepared from shining waterproof paint, and the shining waterproof paint is prepared from the following raw materials: polyhydric alcohol, polyamide-shining microspheres, an isocyanate curing agent, a catalyst, a chain extender, a flatting agent, a wetting agent and deionizedwater, wherein the polyamide-shining microspheres are composed of shining microspheres and polyacrylamide layers covering the shining microspheres. According to the shining waterproof zipper, by adopting polyacrylamide for conducting covering treatment on the shining microspheres, the shining microspheres can be evenly dispersed in the deionized water, and can be subjected to cross-linking polymerization with isocyanate, so that the stability of the polyamide-shining microspheres in paint is improved, the coating has good mechanical performance and waterproofness, the durability of the zipperis high, and an ornamental value is high.

Owner:东莞市瑞翔新型材料科技有限公司

Manufacturing method of aluminum alloy packaging bottle material

The invention provides a manufacturing method of an aluminum alloy packaging bottle material. The alloy comprises the following components in percentage by weight: 0.75-0.80% of Fe, 0.60-0.75% of Si, less than 0.9% of Cu, 0.04-0.11% of Mn, less than 0.06% of Mg, less than 0.04% of Zn, 0.02-0.04% of Ti and the balance of Al, totaling 100%. The manufacturing method comprises the following steps: proportionally melting alloy elements, evenly mixing, and casting into a blank ingot; carrying out face milling on the aluminum alloy blank ingot, wherein the single-side face milling quantity is greater than or equal to 12mm, the thickness difference between the two sides is less than or equal to 2.6mm, and the face milling roughness is 0.06-0.15mm; heating the aluminum alloy blank ingot subjected to face milling to 500-560 DEG C within 15-20 hours, keeping the temperature for 6-10 hours, and discharging; rolling the heated aluminum alloy blank ingot in a rolling mill, wherein the thickness of the aluminum alloy blank ingot is distributed by 17-22 passes, and the temperature after hot rolling is kept at 280-320 DEG C; carrying out cold rough rolling by 5-6 times until the thickness is 35-45m, and carrying out interannealing in an annealing furnace; carrying out cold finish rolling on the annealed coil until the thickness of the finished product is 0.17-0.21mm, and selecting the extensibility according to the size and shape to carry out stretch bending and straightening; and cleaning and trimming the straight coil with a cleaning machine, and finally, cutting with cutting equipment according to the technological requirements.

Owner:WUXI LED TRUST PHOTONIC TECH

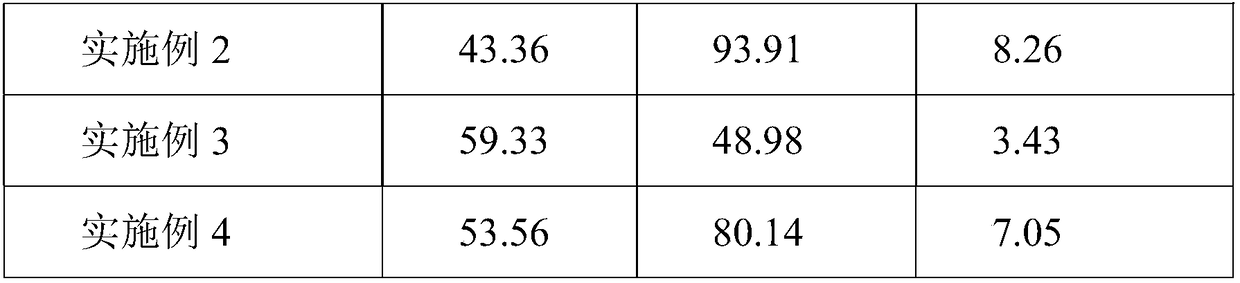

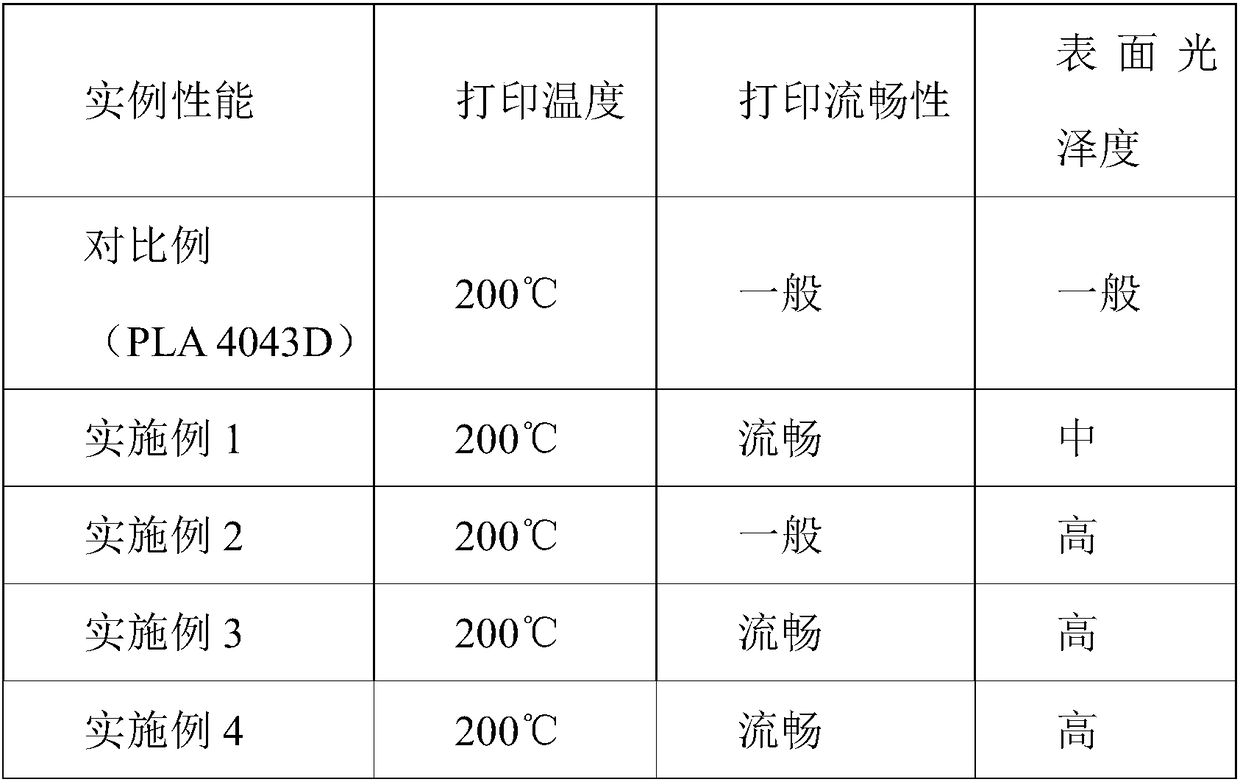

Toughened polylactic acid material for additive manufacturing

InactiveCN108192305AImprove toughnessUniform tensile strengthAdditive manufacturing apparatusUltravioletPhenol

The invention relates to a toughened polylactic acid material for additive manufacturing. The toughened polylactic acid material comprises the following components in percentage by weight: 75-90% of polylactic acid, 8-22% of a polyurethane elastomer, 0.1-0.3% of styrene / acrylic acid polymer, 0.2-0.4% of a hindered phenol antioxidant, 0.2-0.4% of a sulfur-containing auxiliary antioxidant, 0.1-0.3%of a benzophenone ultraviolet absorber, 1-2% of a lubricant and 0.2-0.3% of diffusion oil. The toughened polylactic acid material provided by the invention has the beneficial effects that the toughness of the obtained polylactic acid material is greatly improved and the elongation at break is greatly improved by adjusting the contents of the polyurethane elastomer and the styrene / acrylic acid polymer and adjusting other components, and the product has high glossiness and shows silk luster, so that the surface quality of the product is not influenced by printing layer lines in a printing process of a wire rod.

Owner:诺思贝瑞新材料科技(苏州)有限公司

Core/shell fluoropolymer

InactiveUS20150021814A1Uniform tensile strengthHigh tensile strengthSynthetic resin layered productsCellulosic plastic layered productsVinyl etherTetrafluoroethylene

A core / shell polymer is provided and is optionally heat aged, wherein the core comprises one of (a) melt-fabricable tetrafluoroethylene / perfluoro(alkyl vinyl ether) copolymer and (b) melt-processible polytetrafluoroethylene and the shell comprises the other of (a) and (b), wherein the amount of (b) in said core / shell polymer is 15 to 45 wt % based on the total weight of (a) and (b) whether (b) is the core or shell of the core / shell polymer.

Owner:THE CHEMOURS CO FC LLC

A kind of membrane material for infusion soft bag and its application

ActiveCN104354417BEliminate hazardsProtect healthSynthetic resin layered productsPharmaceutical containersThermoplasticWax

The invention relates to a membrane material for a transfusion soft bag and application of the membrane material. The membrane material is obtained by at least co-extruding an outer layer material, a middle layer material and an inner layer material, wherein the outer layer material comprises PP (Polypropylene), PE (Polyethylene) and SEBS (Styrene-Ethylene-Butadiene-Styrene segmented copolymer), wherein the PP accounts for 60wt%-99wt%, the PE accounts for 0.5wt%-30wt% and the SEBS accounts for 0.2wt%-20wt%; the middle layer material comprises PP, PE and SEBS, wherein the PP accounts for 20wt%-90wt%, the PE accounts for 0.5wt%-20wt% and the SEBS accounts for 0.2wt%-65wt%; and the inner layer material comprises PP, SEBS, TPO (Thermoplastic Polyolefin) and polyolefin wax, wherein the PP accounts for 37wt%-99wt%, the SEBS accounts for 0.1wt%-30wt%, the TPO accounts for 0.2wt%-9wt% and the polyolefin wax accounts for 0.1wt%-7wt%. The membrane material for the transfusion soft bag does not contain PVC (Polyvinyl Chloride) or DEHP (Diethylhexyl Phthalate) and a heat transfer film can be used for printing words or coating colors and printing; the membrane material for the transfusion soft bag has good low-temperature resistance falling performance and separation performance; and a false welding connection part can be formed in the inner layer to prepare the multi-chamber transfusion soft bag.

Owner:LANGHUO MEDICAL MATERIAL BEIJING

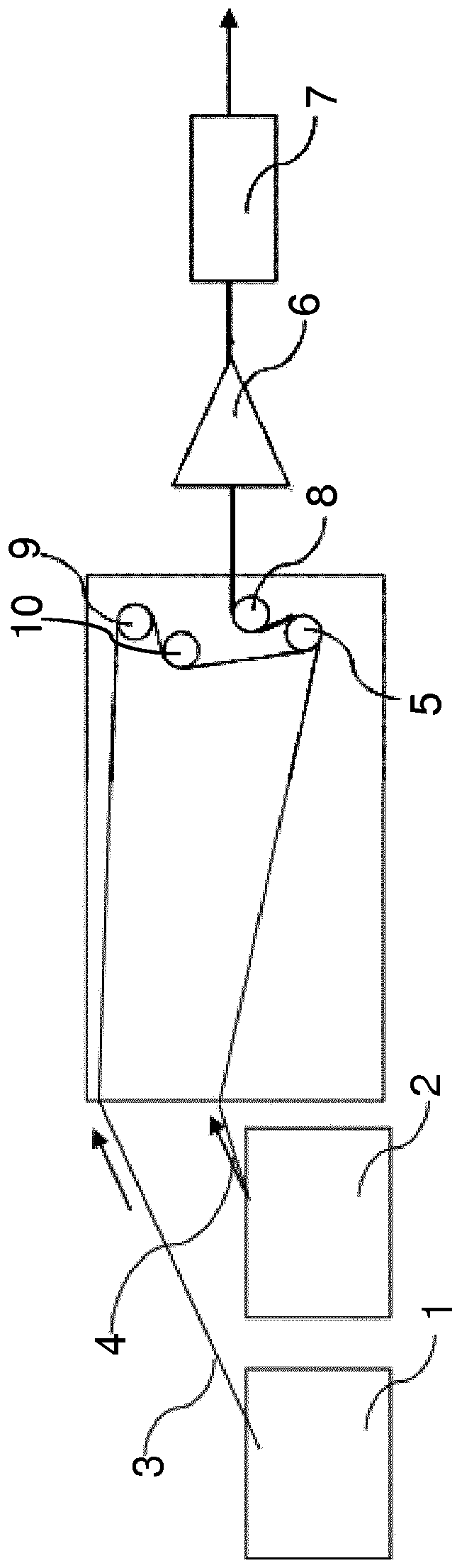

Apparatus and method for forming filter rods

ActiveCN110381755AUniform tensile strengthUniform treatmentTobacco smoke filtersEngineeringFilter material

The invention relates to an apparatus for forming filter rods for aerosol-generating articles. The apparatus comprises a first and a second source, the first source being provided to supply filter material in the form of a first tow, and the second source being provided to supply filter material in the form of a second tow. The apparatus further comprises a single driven delivery roller for advancing the first tow and the second tow and an extrusion tool for processing the first tow and the second tow. The delivery roller is arranged such that the first and second tows are advanced from the first and second source towards the extrusion tool by the delivery roller only. The extrusion tool is configured to process several sources of filter material simultaneously to create one filter rod. The invention also relates to a method for forming filter rods for aerosol-generating articles.

Owner:PHILIP MORRIS PROD SA

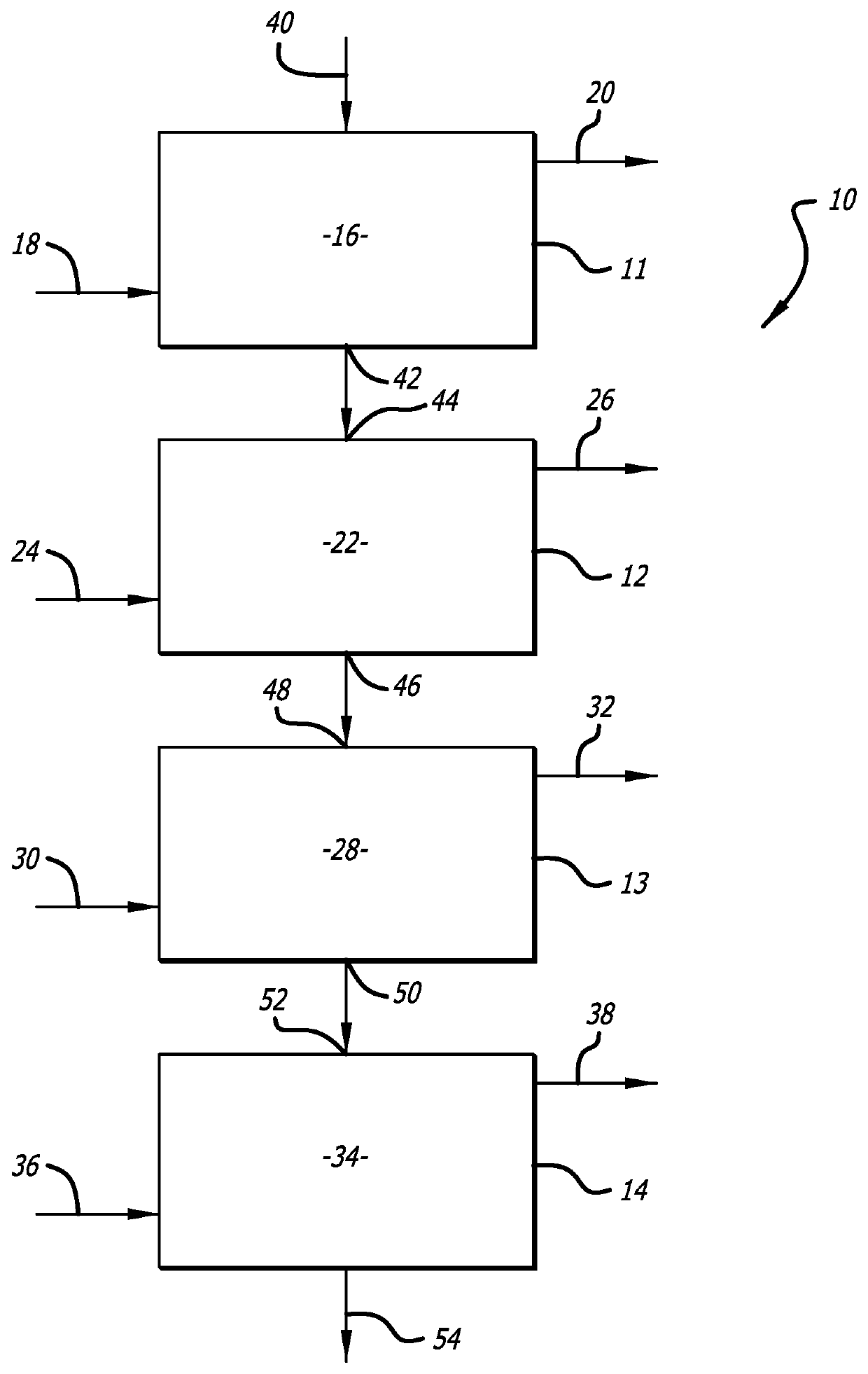

Selective control of oxidation atmospheres in carbon fiber production

ActiveUS11299824B2High strengthTensile strengthArtificial filament heat treatmentCarbon preparation/purificationFiberCarbon fibers

Owner:HEXCEL

A coiled steel bar grouting connector

ActiveCN105064618BReduce lateral stiffnessHigh tensile strengthBuilding reinforcementsSteel barMechanical property

The invention discloses a coiled material steel bar grouting connector, and belongs to the field of a preassembled building structure in the civil engineering. The coiled material steel bar grouting connector comprises a coiled material, expansive mortar and a support frame, wherein the coiled material is a soft coiled building material; the support frame is provided with transverse and / or longitudinal stress bars; the expansive mortar is connected with steel bars; the coiled material is wound around the outer surface of the support frame; and the expansive mortar is injected into the coiled material. The coiled material steel bar grouting connector can be used for connecting steel bars between assembled components. The coiled material steel bar grouting connector can be arranged at a connecting joint part of the assembled components in the engineering, can bear the axial tension generated by building components under the load effect, and can enable the building material at the joint part to be subjected to coordinate deformation. The coiled material steel bar grouting connector has the advantages that the structural form is simple and free; the mechanical property is reliable; the installation is convenient and fast; the industrialization can be realized; and the coiled material steel bar grouting connector has wide engineering application prospects.

Owner:BEIJING UNIV OF TECH

Electrolytic copper foil, and collector, negative electrode, and lithium battery comprising same

ActiveUS10158119B2Increased grain mean diameterUniform tensile strengthElectrode carriers/collectorsNegative electrodesMean diameterElectrolysis

Disclosed is an electrolytic copper foil obtained by heat treating a copper foil manufactured through electrolysis, the electrolytic copper foil having specific resistivity of 1.68 to 1.72 μΩ·cm and a grain mean diameter of a crystallite of 1.0 to 1.5 μm.

Owner:ILJIN MATERIALS CO LTD

A method for preparing layered composite materials by spark plasma sintering

Owner:HARBIN INST OF TECH

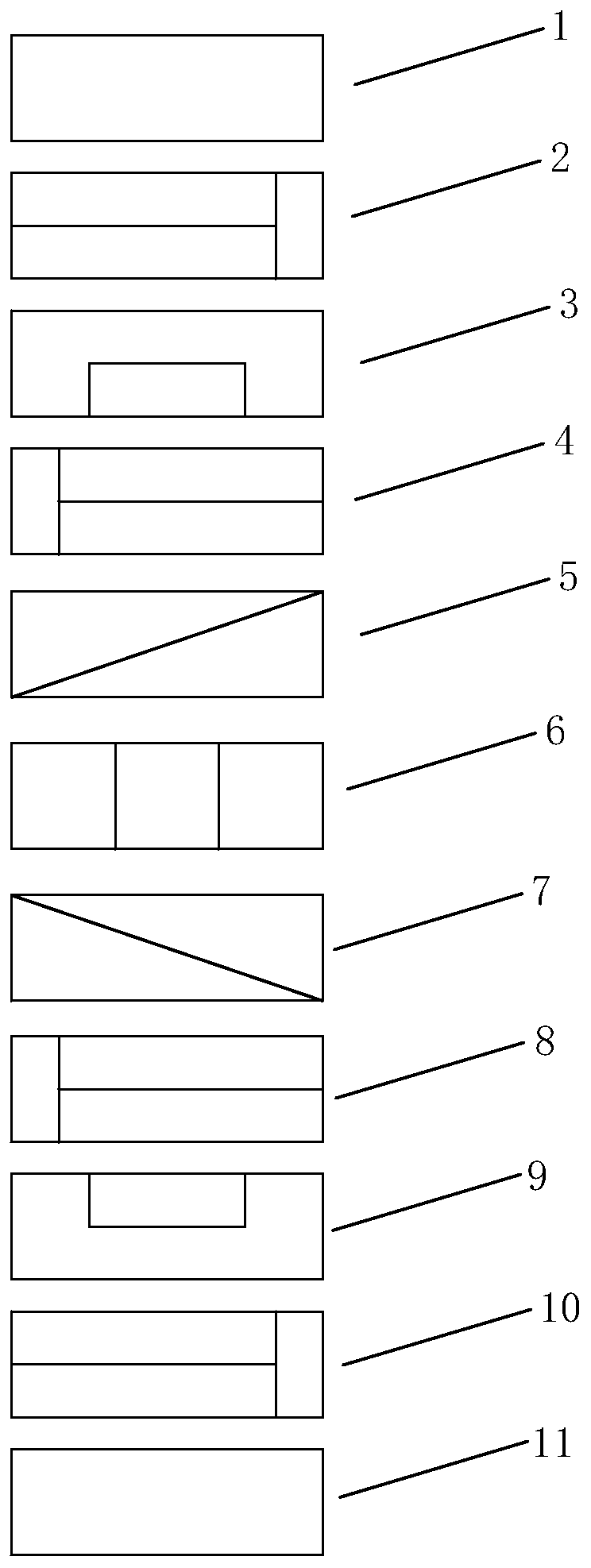

Multilayer structure inverted formwork with high strength

InactiveCN109881883AGuaranteed to be smoothIntegrity guaranteedForming/stuttering elementsSurface layerHigh intensity

The invention relates to the technical field of building wood, in particular to a multilayer structure inverted formwork with high strength. Compared with the prior art, a surface layer and a bottom layer of the multilayer structure inverted formwork with the high strength adopt complete single-piece sheets, and thus surface smoothness and the integrity of all the layers can be ensured; the secondlayer, the fourth layer, the eighth layer and the tenth layer are each in a T shape spliced by three sheets, and thus transverse tensile strength can be improved; a large sheet and a small sheet areadopted to be spliced in an embedded mode on each of the third layer and the ninth layer, and thus longitudinal tensile strength can be improved; the fifth layer and the seventh layer are each formedby two triangular sheets in a spliced mode, and thus stability can be improved; three identical sheets are transversely spliced side by side on the sixth layer, and thus the uniform tensile strength of all the positions in the up-down direction of composite plates can be ensured; and the tensile strength in all the directions can be improved effectively by all the layers of splicing structures, splicing seams are reduced, and the product quality is improved.

Owner:泉州市泉港区锋仕机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com