Multilayer structure inverted formwork with high strength

A multi-layer structure, high-strength technology, applied in the field of construction wood, can solve the problems of easy fracture and deformation, poor tensile strength, etc., and achieve the effect of improving product quality, uniform tensile strength, and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

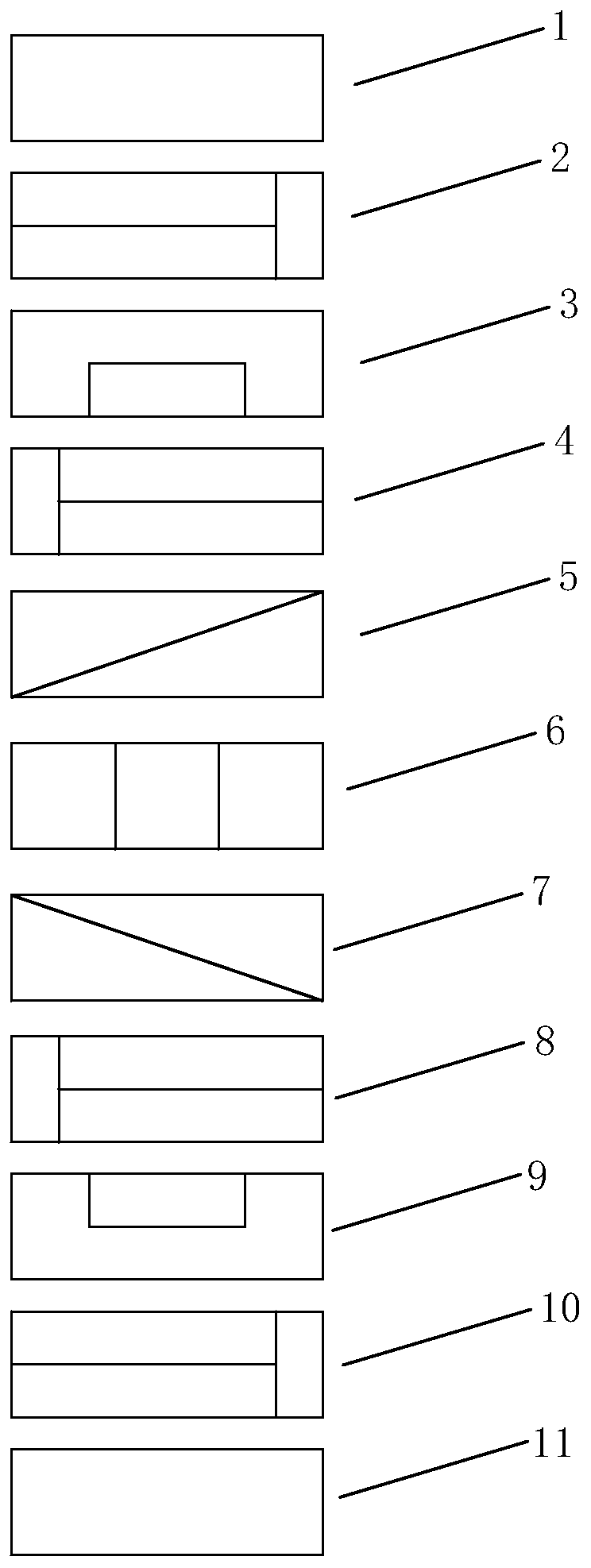

[0008] Such as figure 1 As shown, the high-strength multi-layer structure inverted formwork of the present invention adopts eleven-layer thin plates to be formed by glue bonding and pressing, and the surface layer 1 and the bottom layer 11 adopt a complete single-piece sheet, that is, the surface layer 1 and the bottom layer 11 are a whole board, and Splicing is not required, and the use of a complete single-piece veneer can ensure the smoothness of the surface and the integrity of each layer, and there will be no splicing gaps to meet the surface matching requirements of the formwork and facilitate processes such as painting and polishing.

[0009] Such as figure 1 As shown, the second layer 2, the fourth layer 4, the eighth layer 8 and the tenth layer 10 are spliced by three thin boards, two of which are long boards, one is a short board, and the two long boards are Longitudinal symmetrical distribution, the splicing line is horizontal, and the short plate is spliced wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com