Apparatus and method for forming filter rods

A filter and equipment technology, applied in applications, e-liquid filter elements, tobacco, etc., can solve the problems of high waste of extrusion tools, different tow strength, etc., and achieve uniform processing, uniform pulling strength, and quality increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

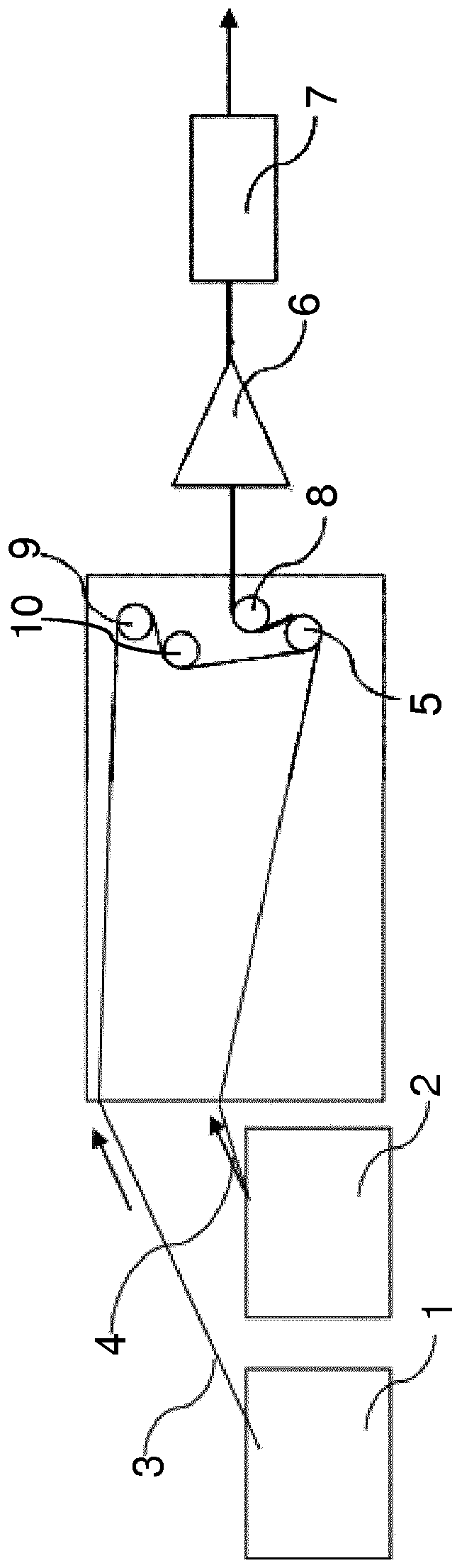

[0027] figure 1 The shown device comprises a first source 1 and a second source 2 . Both sources include filter material.

[0028] Cellulose acetate can be used as filter material. The filaments may subsequently be treated with a plasticizer to promote interfiber bonding of the various filaments, including tows, for the purpose of providing the filler with uniform density and overall cohesive characteristics. The tow may comprise a plurality of cellulose acetate filaments extending longitudinally and coextensively along the mass of the tow. The cellulose acetate may have a total denier of 25,000 to 75,000, more preferably in the range of 30,000 to 50,000, the foregoing being based on a fiber denier of about 1 to 16 and preferably 3 to 6 denier. Other materials are suitable for use as fillers and may include polyolefins, polyethylene and paper tow.

[0029] As a preliminary process for forming filter rods, the filter material described in representative form as a cellulose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com