A method for preparing layered composite materials by spark plasma sintering

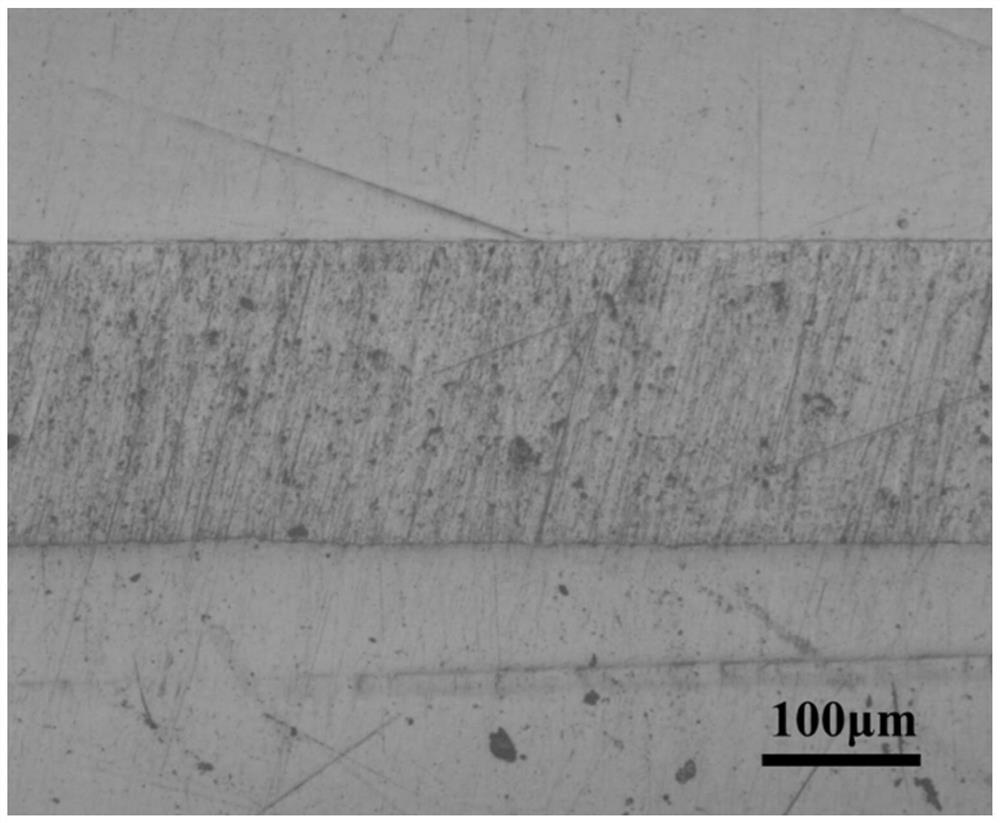

A technology of layered composite materials and discharge plasma, which is applied in the field of preparing layered composite materials, can solve the problems of low bonding strength of layered composite materials, and achieve the effects of shortening the holding time, high sintering temperature, and smooth composite interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

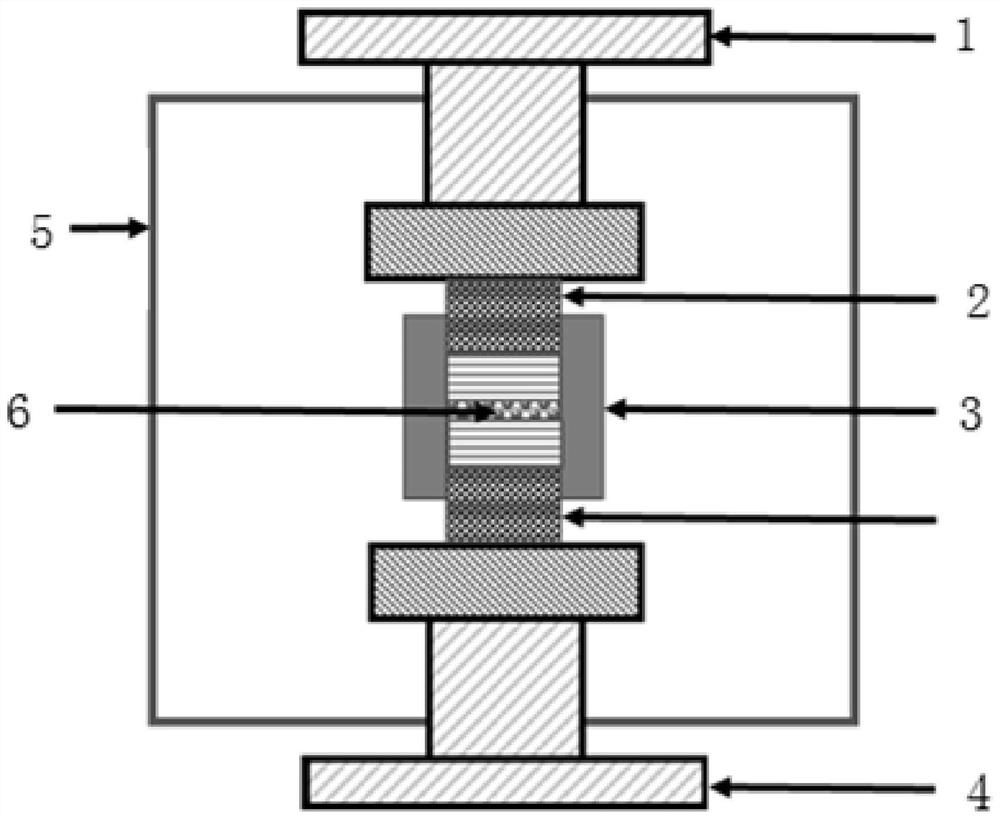

[0020] Embodiment 1: In this embodiment, the method for preparing a layered composite material by spark plasma sintering is carried out according to the following steps:

[0021] First, roughen the surface of the metal sheet until the roughness is greater than Ra12.5 and clean it with alcohol, then stack the multi-layer metal sheets, and spread a layer of metal powder between adjacent metal sheets to form a sheet-powder stack Layer component, place the plate-powder laminated component in the graphite mold, apply pressure to the plate-powder laminated component in the graphite mold, and carry out spark plasma sintering, which is completed;

[0022] The melting point of the metal powder is 0.5 to 0.9 times the lower melting point of the metal sheets on both sides; the materials of the metal powders in different layers in the sheet-powder laminated component are one or more; the The metal sheets of different layers in the sheet-powder laminated component are made of one or more m...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the material of the metal plate is pure metal or metal alloy; the pure metal is Fe, Ni, Ti, Cu, Zn, Al, Mg or W ; The metal alloy is an alloy whose main component is Fe, Ni, Ti, Cu, Zn, Al, Mg or W. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment is different from Embodiment 1 in that: the thickness of the metal plate is 0.05-10 mm. Other steps and parameters are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com