Method and device for making extension net slice and battery using the extension net slice

A manufacturing method and a manufacturing device technology, which are applied in the directions of electrode manufacturing, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as difficulty in manufacturing extended mesh sheets, and achieve improved welding reliability, good current collection, and The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

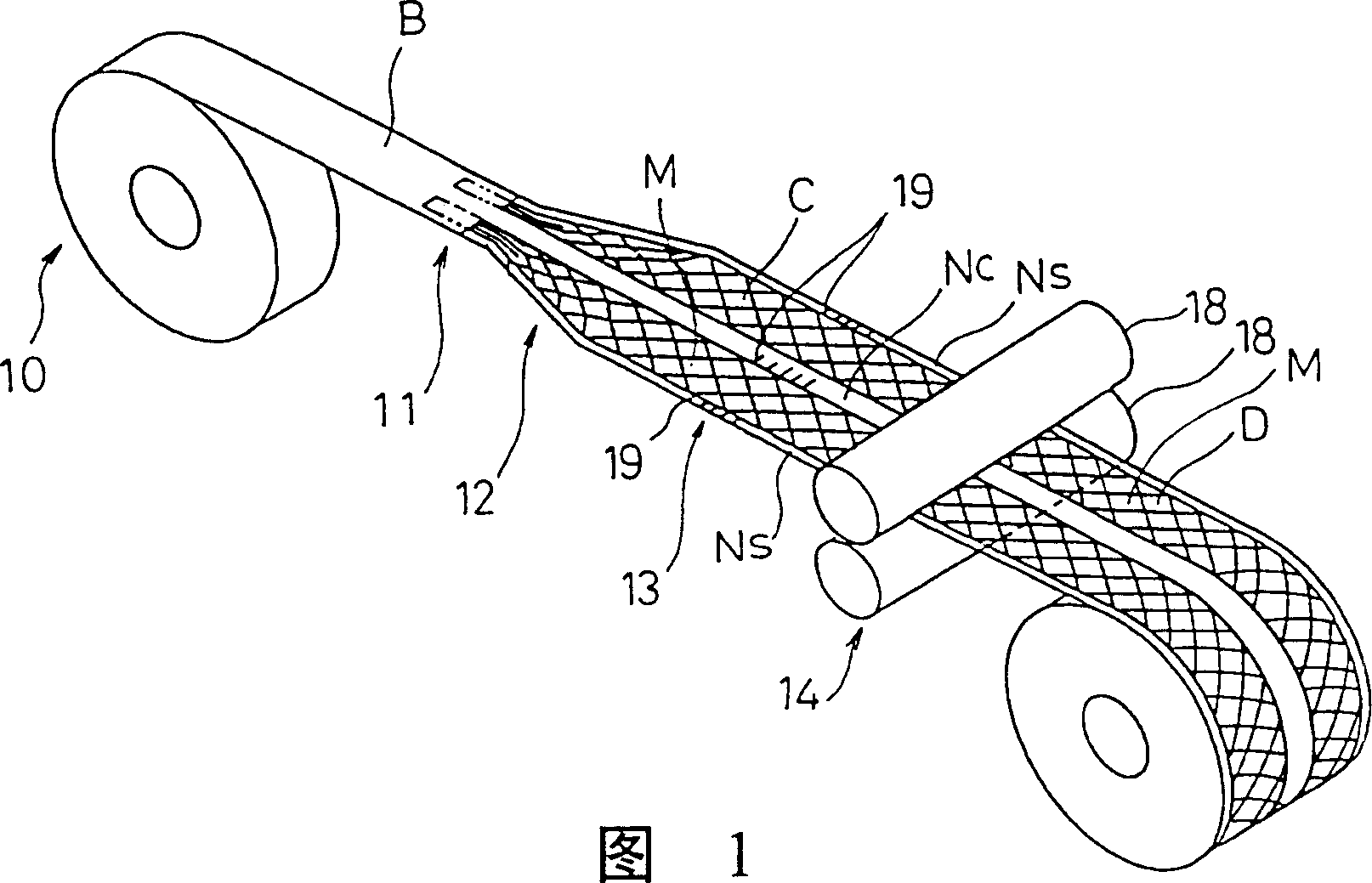

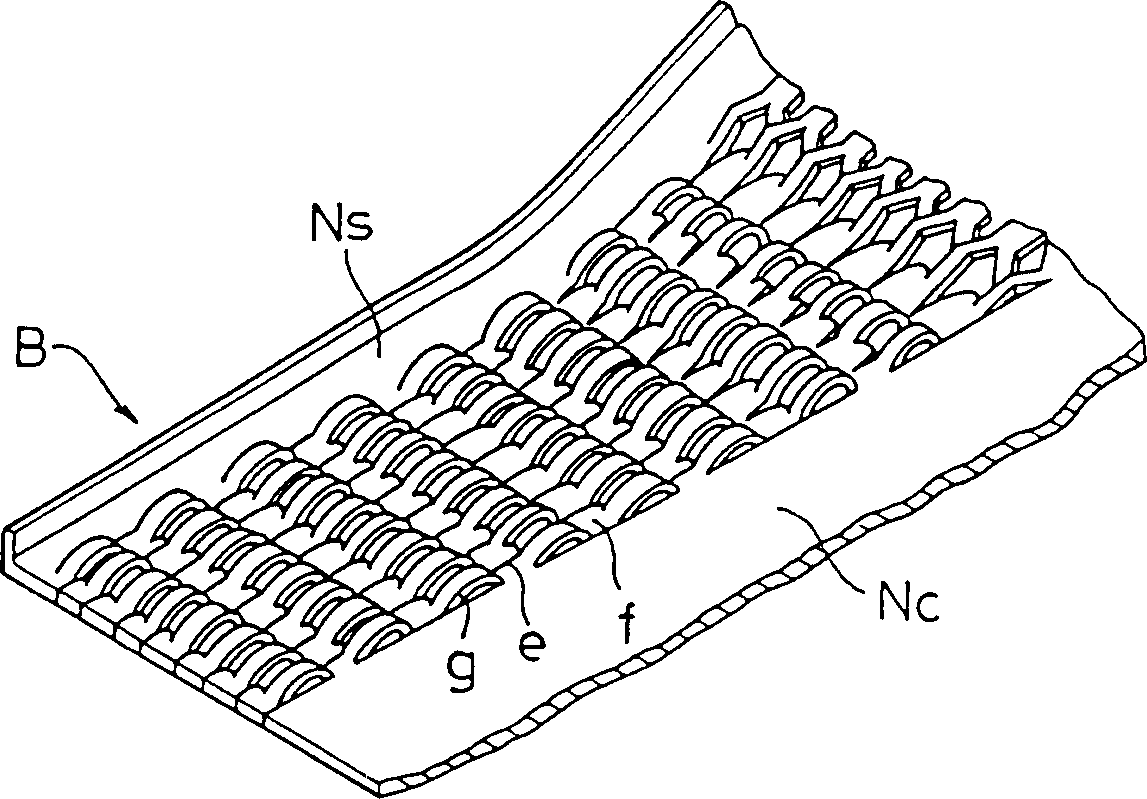

[0052] Combined with Figure 1~ Figure 8 One embodiment of the present invention will be described.

[0053] Fig. 1 shows the processing steps performed by the method of manufacturing the expanded mesh sheet of the present invention. The extended mesh sheet of the present embodiment forms fine meshes on a thin strip metal sheet, such as a copper sheet or an aluminum sheet, and at the same time, a blank portion without meshes is provided at its central part and both sides, as a structure for forming a non-aqueous electrolyte battery. The current collector of the electrode plate is used.

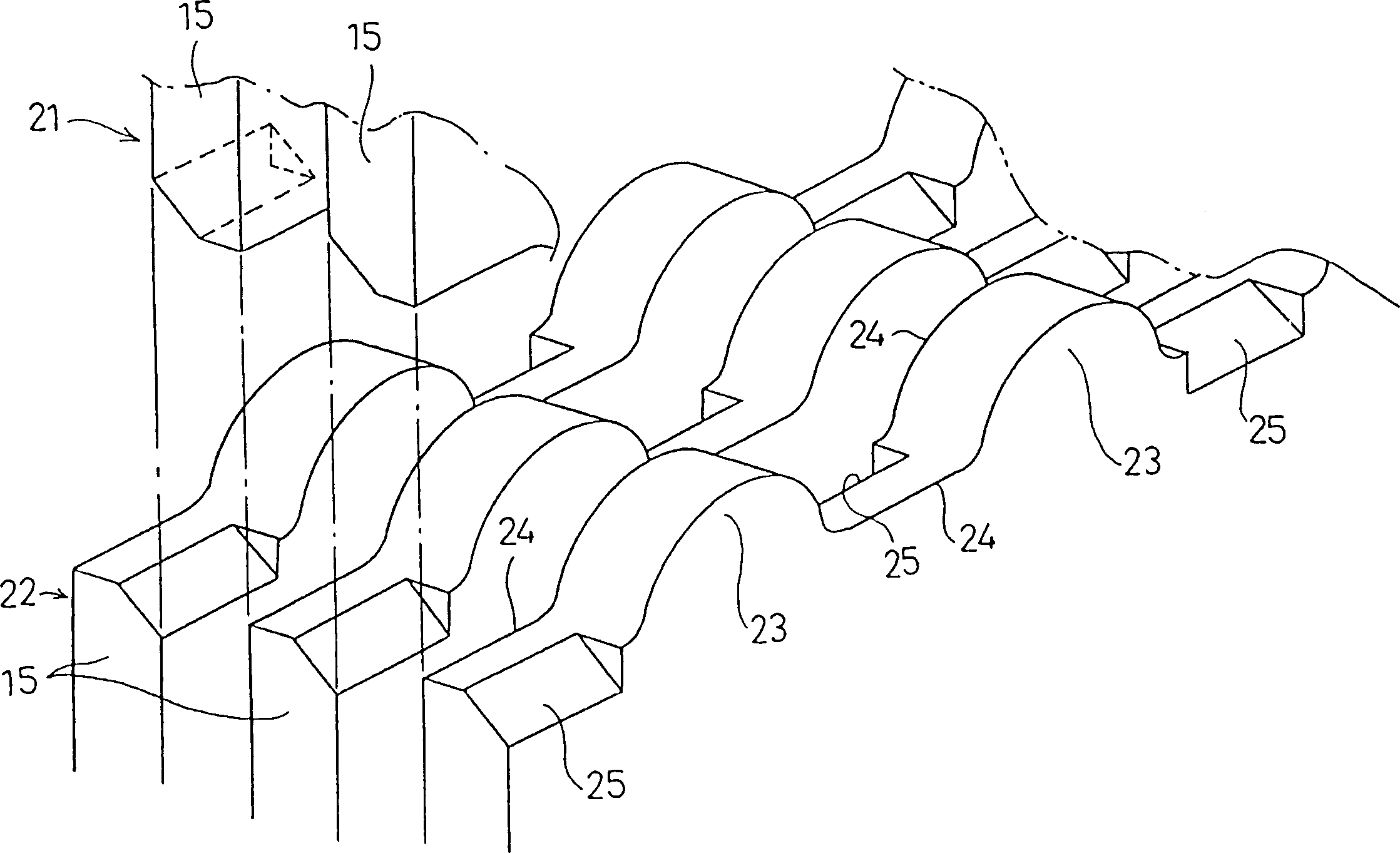

[0054] In FIG. 1 , the elongated metal sheet B spirally wound around the coil part 10 is pulled out from the end and sent to the slit forming part 11 . In the slit forming part 11, the upper mold and the lower mold, which are formed by overlapping the plate-shaped cutters described later, are arranged oppositely, and are driven forward and backward by the opposite direction, such as figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com