Toughened polylactic acid material for additive manufacturing

A polylactic acid material and additive manufacturing technology, applied in the field of polylactic acid materials and toughening polylactic acid materials, can solve the problems of low surface gloss and insufficient toughness, and achieve high surface gloss, good fluidity and improved mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

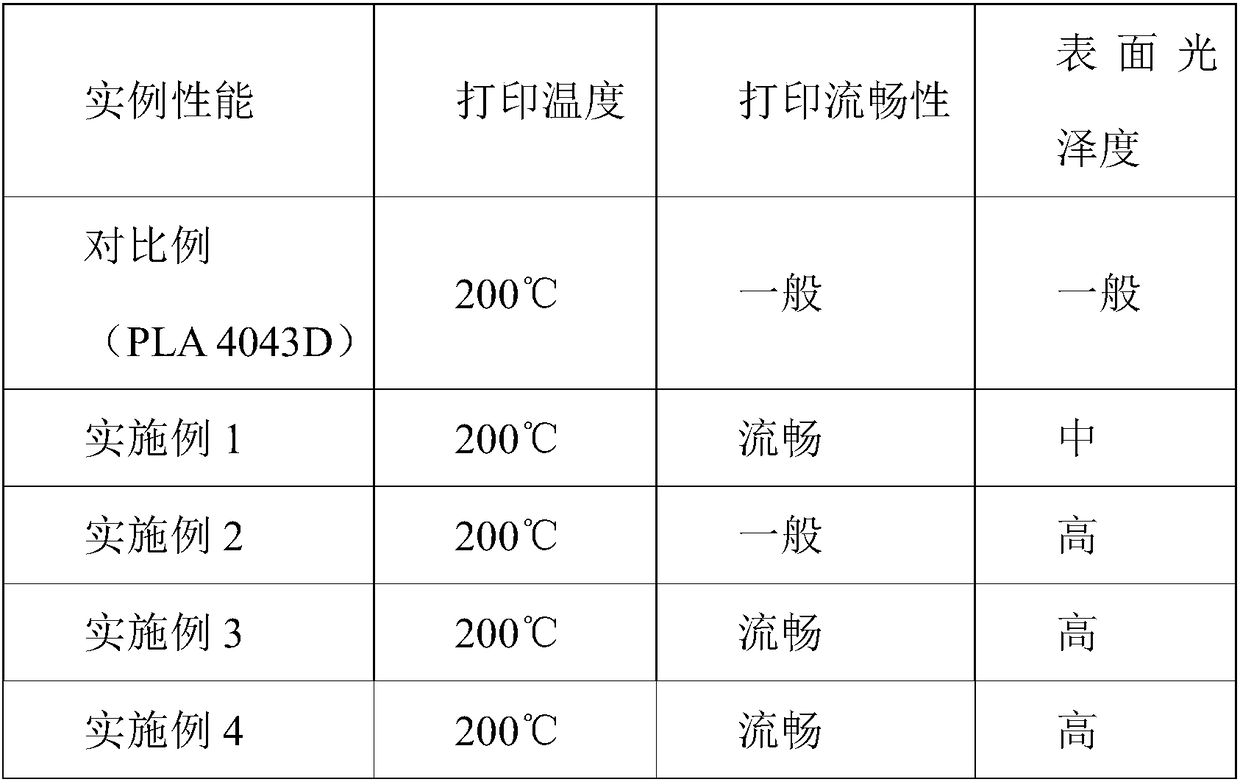

Embodiment 1

[0031] The polylactic acid and styrene / acrylic acid polymers were respectively placed in an airflow drying oven, and dried at 65° C. for 4 hours to ensure that their moisture content was controlled below 0.05%. Place the polyurethane elastomer in a vacuum oven at 70°C to dry for 4 hours to ensure that its moisture content is also controlled below 0.05%.

[0032] Then the dried polylactic acid, styrene / acrylic acid polymer, and polyurethane elastomer are proportioned according to the weight percentage of the entire polylactic acid material obtained, wherein 90% of polylactic acid PLA and 8% of polyurethane elastomer TPU are put into high-mixing Mix in the machine at low speed for 10 seconds, and the mixing temperature does not exceed 50°C. After mixing, add diffuser oil DSP 0.2% and mix at low speed for 5 seconds. Observe that the material particles are evenly covered with dispersing oil, and then add styrene / acrylic acid polymer ADR 0.1%, hindered phenolic antioxidant 1010 0.2...

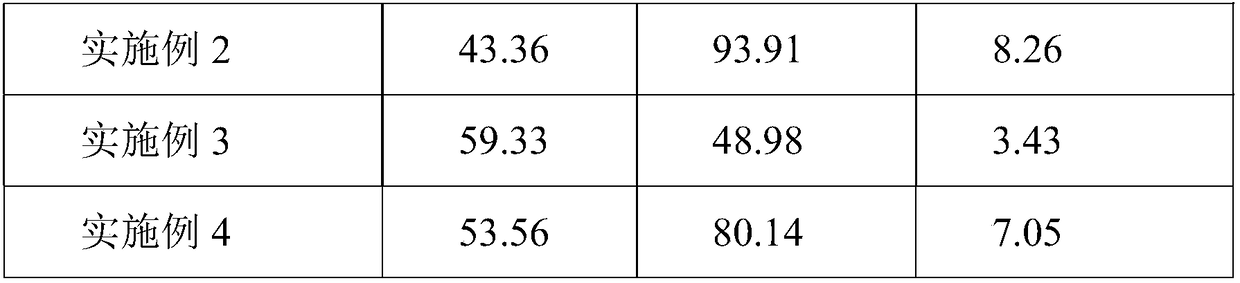

Embodiment 2

[0036] The polylactic acid and styrene / acrylic acid polymers were respectively placed in an airflow drying oven, and dried at 65° C. for 4 hours to ensure that their moisture content was controlled below 0.05%. Place the polyurethane elastomer in a vacuum oven at 70°C to dry for 4 hours to ensure that its moisture content is also controlled below 0.05%.

[0037]The dried materials of polylactic acid, styrene / acrylic acid polymer and polyurethane elastomer are proportioned according to the weight percentage of the whole polylactic acid material, among which polylactic acid PLA75% and polyurethane elastomer TPU22% are put into the high mixer Mix at medium and low speed for 15 seconds, and the mixing temperature does not exceed 50°C. After mixing, add 0.3% dispersing oil DSP and mix at low speed for 15 seconds, and observe that the material particles are evenly covered with dispersing oil. Then put styrene / acrylic acid polymer ADR 0.3%, hindered phenolic antioxidant 1010 0.2%, su...

Embodiment 3

[0041] The polylactic acid and styrene / acrylic acid polymers were respectively placed in an airflow drying oven, and dried at 65° C. for 4 hours to ensure that their moisture content was controlled below 0.05%. Place the polyurethane elastomer in a vacuum oven at 70°C to dry for 4 hours to ensure that its moisture content is also controlled below 0.05%.

[0042] The dry materials of polylactic acid, styrene / acrylic acid polymer and polyurethane elastomer are proportioned according to the weight percentage of the whole polylactic acid material, among which polylactic acid PLA88% and polyurethane elastomer TPU 9% are put into high-mixing Mix in the machine at low speed for 15 seconds, and the mixing temperature does not exceed 50°C. After mixing, add dispersing oil DSP 0.2% and mix at low speed for 15 seconds, and observe that the material particles are evenly covered with dispersing oil. Then put in styrene / acrylic acid polymer ADR 0.3%, hindered phenolic antioxidant 1010 0.2%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com