Steel sheet

a technology of steel sheets and tensile steel, applied in the field of steel sheets, can solve the problems of deterioration of weldability, impaired formability of steel sheets, and often subjected steel sheets to welding, and achieve excellent weldability, tensile strength and uniform elongation, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

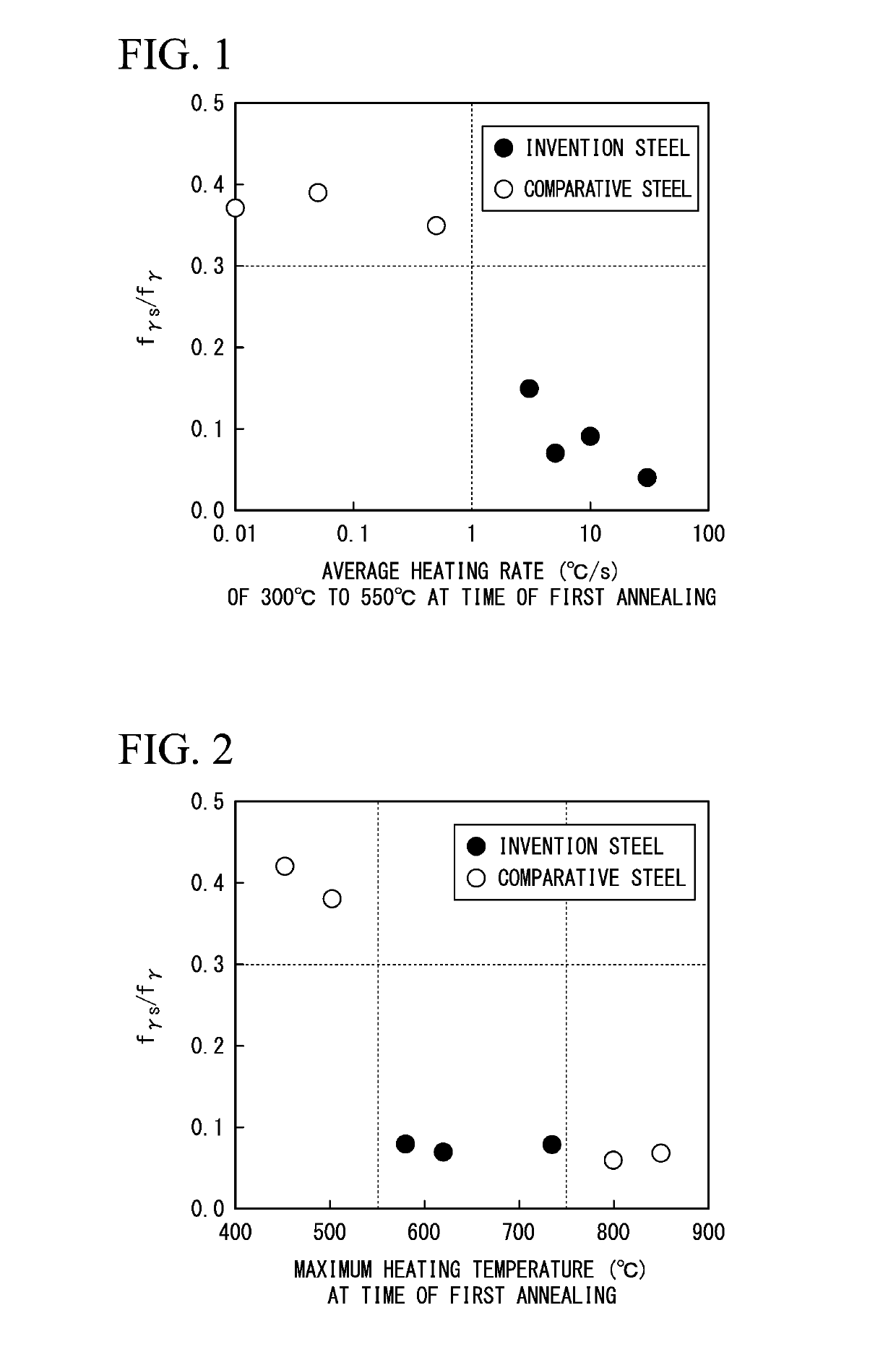

[0137]First, in order to investigate the influence of the heating rate in the first annealing, an experiment was performed as described below.

[0138]A slab having the chemical composition, by unit mass %, consisting of C: 0.10%, Si: 1.0%, Mn: 4.3%, P: 0.010%, S: 0.0020%, Al: 0.03%, N: 0.0020%, O: 0.0012%, and the remainder was Fe and impurities was produced by using a vacuum melting furnace. The obtained slab was heated to 1,200° C. and was subjected to hot rolling at the finishing temperature of 921° C. Thereafter, the slab was cooled at the average cooling rate set to 50° C. / s within the temperature range from 800° C. to the coiling start temperature and was wound at 450° C. After the wound hot rolled steel sheet was cooled to room temperature, the first annealing was performed. In heating before the first annealing, the average heating rate within the temperature range of 300° C. to 550° C. was set to various values within a range of 0.01° C. / s to 30° C. / s. The annealing temperatu...

example 2

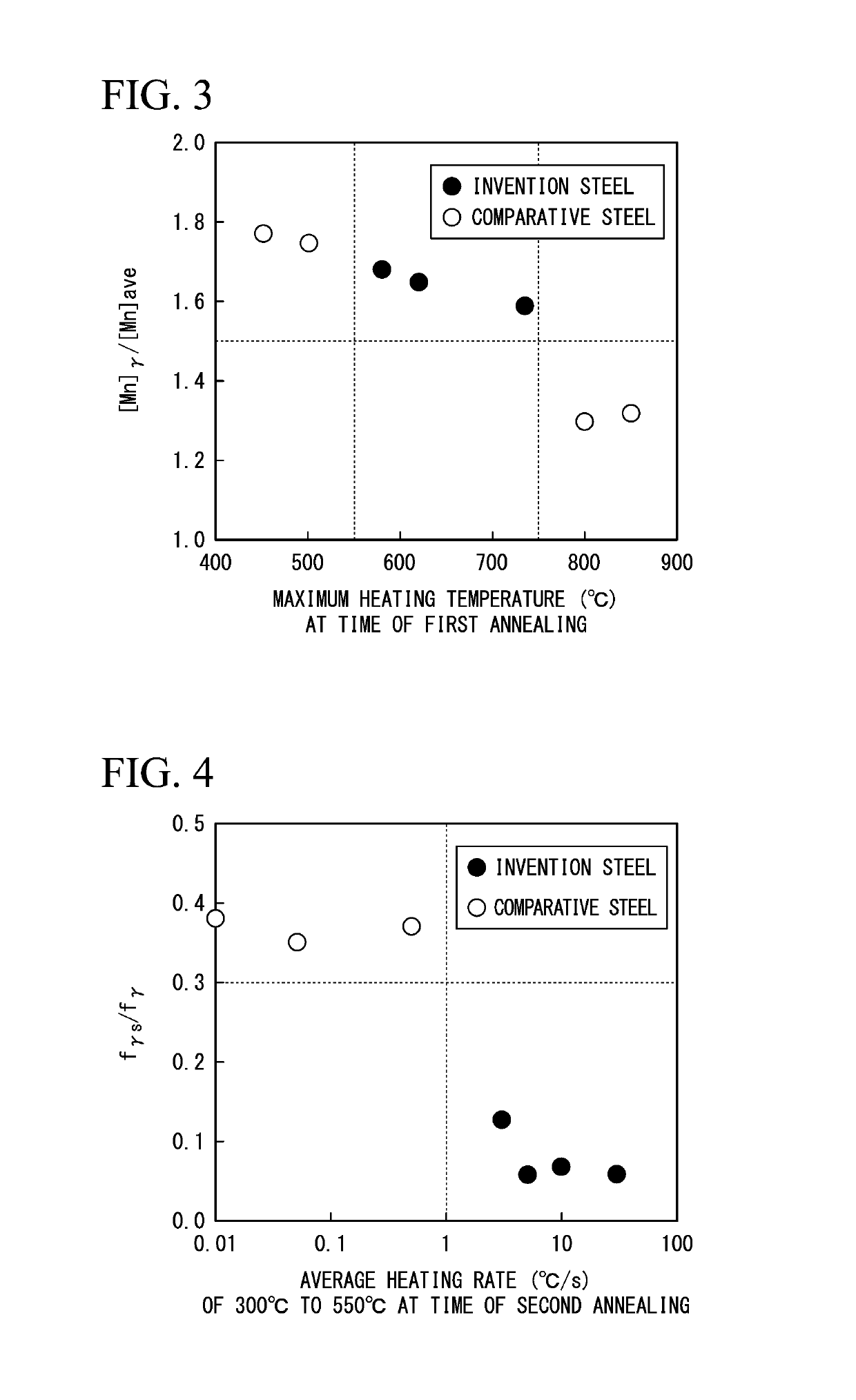

[0142]Next, in order to investigate the influence of the annealing temperature in the first annealing, an experiment was performed as described below.

[0143]The slab used in Example 1 was heated to 1,200° C. and was subjected to hot rolling at the finishing temperature of 921° C. Thereafter, the slab was cooled at the average cooling rate of 50° C. / s within the temperature range from 800° C. to the coiling start temperature, and coiling treatment was performed at 450° C. After the wound hot rolled steel sheet was cooled to room temperature, the first annealing was performed. The average heating rate within the range of 300° C. to 550° C. before the first annealing (in a case where the annealing temperature was less than 550° C., within the range from 300° C. to the annealing temperature) was set to 3.5° C. / s. Subsequently, heating of each of the samples ended at 450° C. to 850° C. Thereafter, each of the samples was retained at each annealing temperature for 7,200 seconds, and then e...

example 3

[0145]Next, in order to investigate the influence of the heating rate in the second annealing, an experiment was performed as described below.

[0146]The slab used in Example 1 was heated to 1,200° C. and was subjected to hot rolling at the finishing temperature of 921° C. Thereafter, the slab was cooled at the average cooling rate set to 50° C. / s within the section from 800° C. to the coiling start temperature, and coiling treatment was performed at 450° C. Thereafter, in the first annealing, each of the samples was heated at the average heating rate of 2.5° C. / s within the range of 300° C. to 550° C., and each of the samples was retained at 590° C. for 7,200 seconds. Then, each of the samples was cooled to room temperature by air cooling. Thereafter, cold rolling at a cold rolling reduction of 52% was performed for each of the samples. Then, each of the samples was heated the average heating rate of 0.01° C. / sec to 30° C. / sec within the range of 300° C. to 550° C. Moreover, after ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| metallographic structure | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com