Environment-friendly modified polyvinyl chloride tight buffering material for soft communication optical cable and preparation method of material

A technology of polyvinyl chloride and polyvinyl chloride resin, which is applied in the field of environment-friendly modified polyvinyl chloride tight sleeve material for communication soft optical cable and its preparation, can solve the problems of low thermal shrinkage rate and the like, and achieves low thermal shrinkage rate and thermal shrinkage resistance. Good performance, good flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

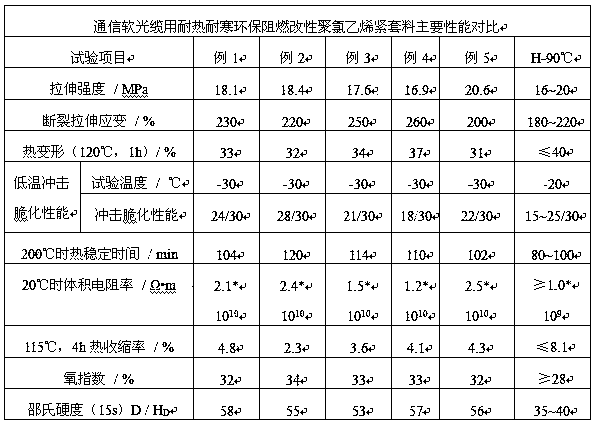

Embodiment 1

[0014] Example 1: Weigh 100kg of SG-3 type polyvinyl chloride resin, 32kg of polyester plasticizer UN488, 6kg of plasticizer DOS, 6kg of calcium-zinc composite stabilizer, 25kg of activated calcium carbonate, 5kg of environmentally friendly antimony trioxide, hard Calcium fatty acid 1 kg, ACR 4kg, CPE 4kg, SBS 3kg. Add the above-mentioned raw materials that have been weighed into the high-speed mixer, mix and pre-plasticize fully at low speed and then high speed for 25 minutes, and use twin-screw extruder to extrude, knead and plasticize, and the temperature of each section of the extruder starts from the feeding port , followed by 110°C, 140°C, 150°C, 130°C; single-screw granulation, single-screw temperature 120°C, head temperature 130°C; air-cooled sieving; metering and packaging.

Embodiment 2

[0015] Embodiment 2: Weigh 95kg of SG-3 type polyvinyl chloride resin, 30kg of polyester plasticizer UN488, 8kg of plasticizer DOS, 5kg of calcium zinc composite stabilizer, 20kg of active calcium carbonate, 8kg of environmental protection antimony trioxide, hard Calcium fatty acid 1.5kg, ACR 3kg, CPE 6kg, SBS 5kg. Add the above-mentioned raw materials that have been weighed into the high-speed mixer first at low speed and then at high speed, fully mix and pre-plasticize for 20 minutes, and use the twin-screw extruder to extrude, knead and plasticize, and the temperature of each section of the extruder starts from the feeding port , followed by 115°C, 135°C, 155°C, 125°C; single-screw granulation, single-screw temperature 125°C, head temperature 135°C; air-cooled sieving; metering and packaging.

Embodiment 3

[0016] Embodiment 3: Weigh 98kg of SG-3 type polyvinyl chloride resin, 35kg of polyester plasticizer UN488, 5kg of plasticizer DOS, 8kg of calcium-zinc composite stabilizer, 30kg of active calcium carbonate, 7kg of environmental protection antimony trioxide, hard Calcium fatty acid 2 kg, ACR 5 kg, CPE 2 kg, SBS 4 kg. Add the above-mentioned raw materials that have been weighed into the high-speed mixer first at low speed and then at high speed, fully mix and pre-plasticize for 30 minutes, and use the twin-screw extruder to extrude, knead and plasticize, and the temperature of each section of the extruder starts from the feeding port , followed by 105°C, 145°C, 160°C, 135°C; using single-screw granulation, the single-screw temperature is 115°C, the head temperature is 125°C; air-cooled and sieved; metered packaging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com