High-temperature-resistant photo-curing material for 3D ink-jet printing, preparation method thereof, 3D printed product and 3D printer

A light-curing material and inkjet printing technology, applied in the field of 3D printing, can solve the problems of low viscosity, low temperature resistance, and restrictions on the application of light-curing materials, and achieve the goals of increasing temperature, highlighting impact resistance, and enhancing mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

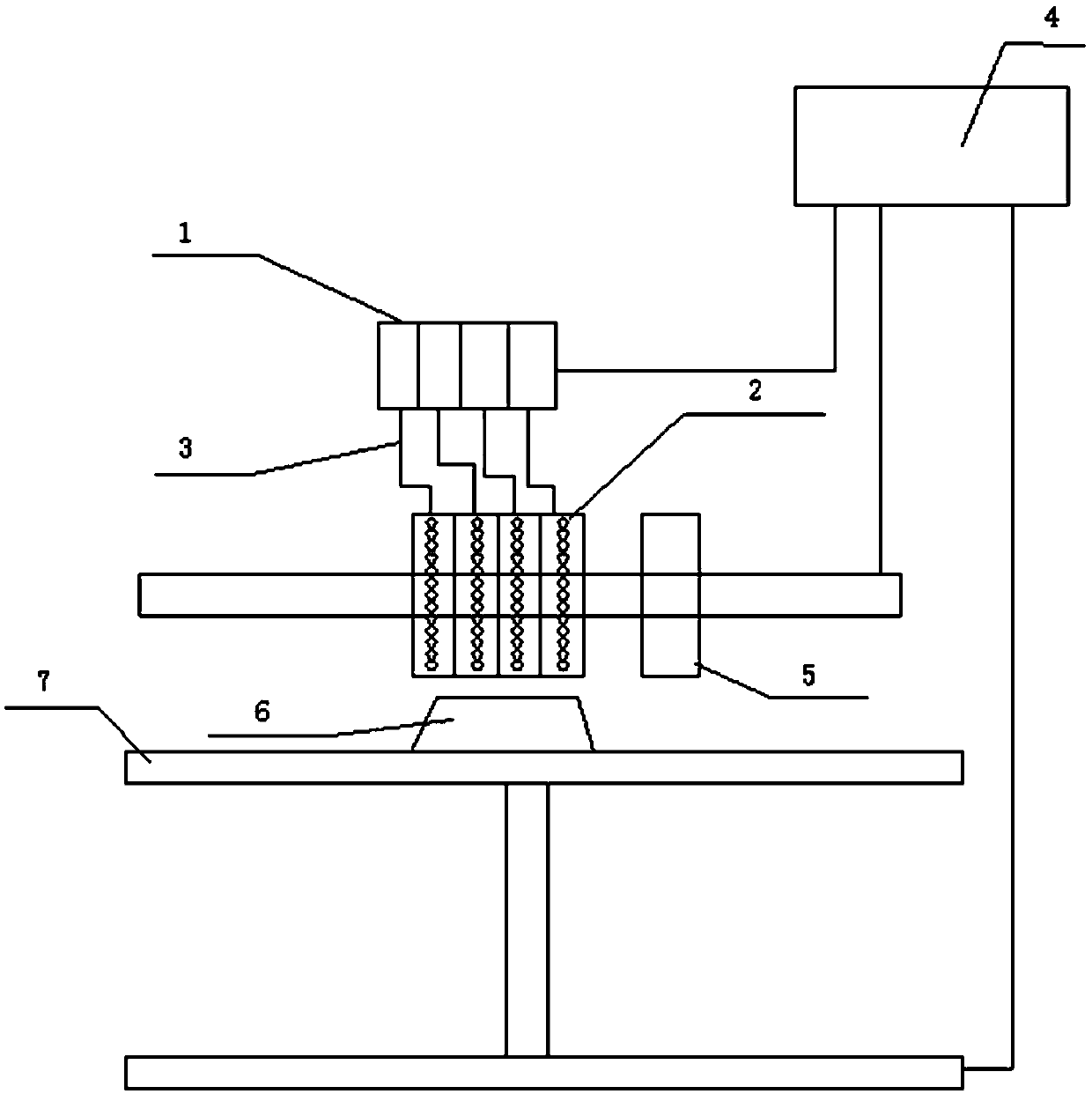

Image

Examples

Embodiment 1

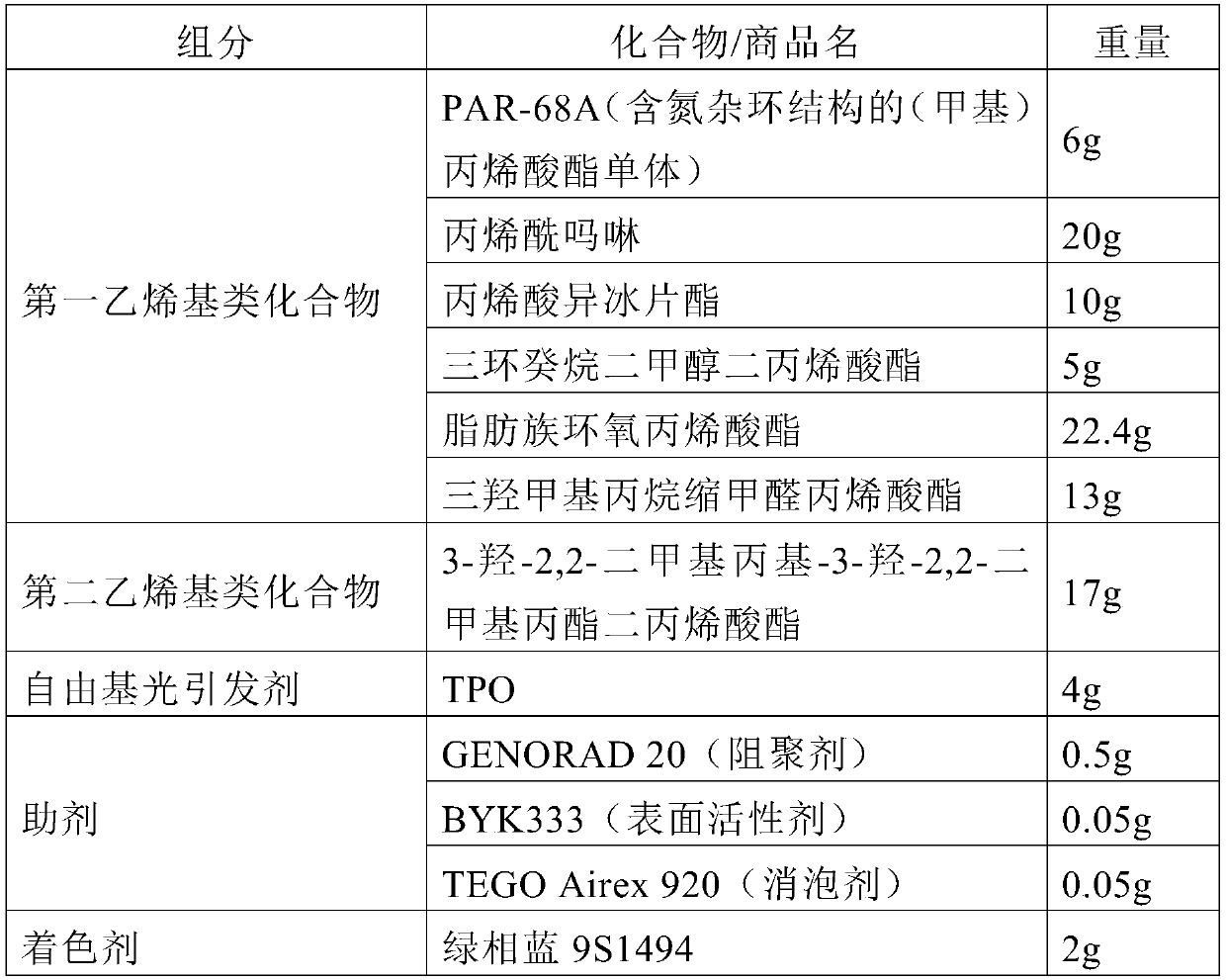

[0084] This embodiment provides a high temperature resistant photocurable material for 3D inkjet printing, which has the composition of the following table 1:

[0085] Composition of high temperature resistant photocurable material for 3D inkjet printing in Table 1 Example 1

[0086]

[0087] The preparation method of the high-temperature photocurable material for 3D inkjet printing is as follows:

[0088] (1) All components except the free radical photoinitiator are placed in a glass container, and stirred with a stirrer to obtain a uniformly mixed first mixture; then add the free radical photoinitiator to the first mixture and continue stirring until the free radical photoinitiator is completely dissolved to obtain the second mixture;

[0089] (2) Carry out primary filtration to the second mixture with a 0.6 μm glass fiber membrane, and then perform secondary filtration with a 0.2 μm polypropylene membrane (PP membrane) to obtain a filtrate;

[0090] (3) Under a vacuum ...

Embodiment 2

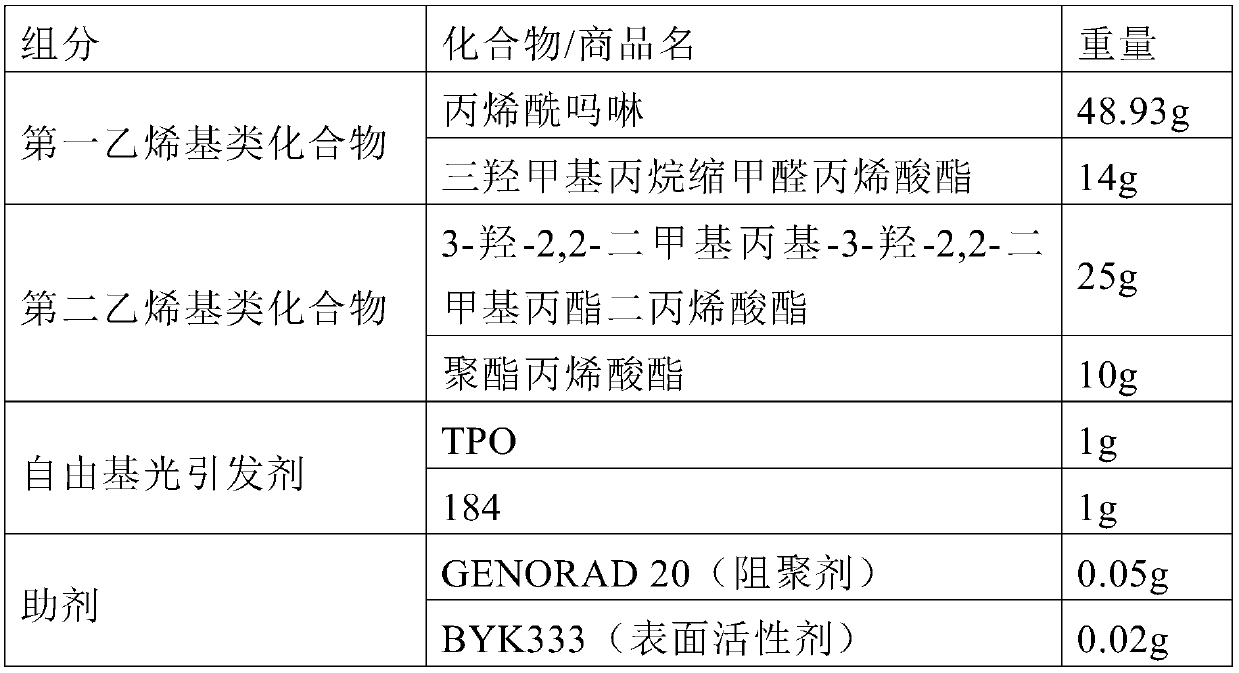

[0092] This embodiment provides a high-temperature photocurable material for 3D inkjet printing, which has the composition of the following table 2:

[0093] Composition of high temperature resistant photocurable material for 3D inkjet printing in Table 2 Example 2

[0094]

[0095] The preparation method of the high-temperature photocurable material for 3D inkjet printing in this example is basically the same as in Example 1, except that the components used are replaced accordingly, and in step (3), the method of heating and degassing is adopted. (2) The obtained filtrate was heated to 40° C. for degassing treatment, and the degassing time was 50 minutes.

[0096] The high-temperature photocurable material for 3D inkjet printing obtained in this embodiment is a transparent material.

Embodiment 3

[0098] This embodiment provides a high temperature resistant photocurable material for 3D inkjet printing, which has the composition of the following table 3:

[0099] Composition of high temperature resistant photocurable material for 3D inkjet printing in Table 3 Example 3

[0100]

[0101] The preparation method of the high-temperature photocurable material for 3D inkjet printing in this embodiment is basically the same as that in Embodiment 1, except that the components used are replaced accordingly, and in step (3), the specific time for decompression and degassing is adjusted to 2 Hour. The high temperature resistant photocurable material for 3D inkjet printing obtained in this embodiment is a red material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com