Preparation method of high-temperature gas filter material for three-dimensional orthogonal woven fabric bag-type dust removal equipment

A technology for high-temperature gas filtration and dust removal equipment, which is applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of short service life and poor mechanical properties of high-temperature filter materials, and achieve low equipment investment and operating costs. High temperature resistance properties and the effect of improving capture efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

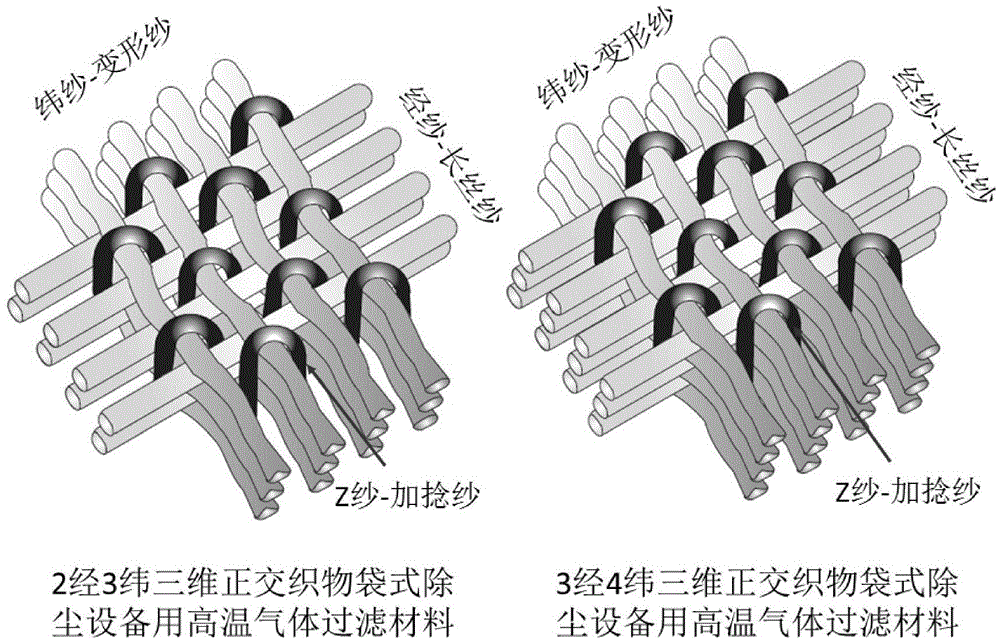

Embodiment 1

[0031] Select the aramid fiber air textured yarn with an overfeed rate of 20% and a linear density of 111tex as the weft yarn; select the carbon fiber filament yarn with a linear density of 200tex as the warp yarn; select 2 strands of 40tex aramid filament twisted plied yarn as the Z yarn , woven into a three-dimensional orthogonal structure fabric with 2 warps and 3 wefts. Wherein, the warp density of the fabric is 6 threads / cm, and the weft density is 6 threads / cm.

Embodiment 2

[0033] Select the aramid fiber air textured yarn with an overfeed rate of 20% and a linear density of 111tex as the weft yarn; select the glass fiber filament yarn with a linear density of 290tex as the warp yarn; select 2 strands of 20tex aramid filament twisted plied yarn as the Z The yarn is woven into a three-dimensional orthogonal structure fabric with 2 warps and 3 wefts. The warp density of the fabric is 5 threads / cm, and the weft density is 6 threads / cm.

Embodiment 3

[0035] Select aramid fiber air textured yarn with an overfeed rate of 10% and a linear density of 111tex as the weft yarn; select basalt fiber filament yarn with a linear density of 462tex as the warp yarn; select 2 strands of 20tex aramid filament twisted plied yarn as the Z The yarn is woven into a three-dimensional orthogonal structure fabric with 2 warps and 3 wefts. The warp density of the fabric is 5 threads / cm, and the weft density is 6 threads / cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com